Exploring thermal Switches

LED's performance:

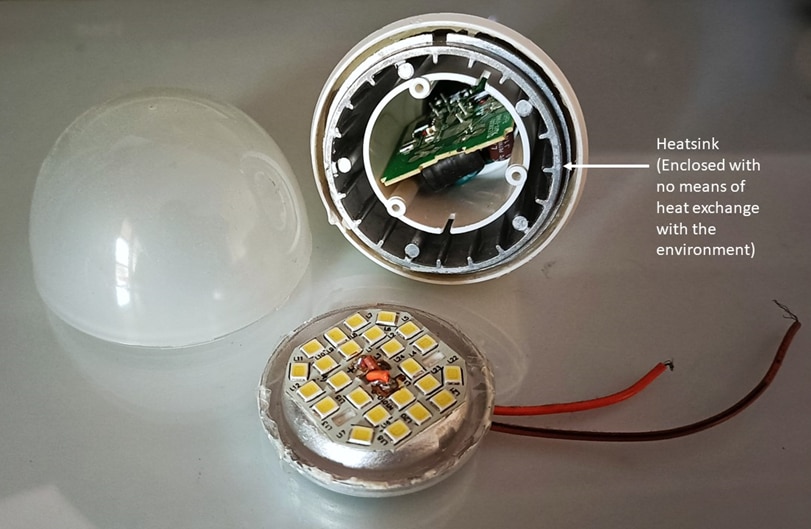

LEDs are known to work better in colder temperatures. With increasing temperature, their performance/light output comes down. The present-day LED bulbs are more compact and only have a heatsink to dissipate heat. Their compact construction is in such a way that the heatsinks have very minimal heat exchange with the atmosphere as they are enclosed in the plastic molding of the bulb.

Operating within the junction temperature rated by the manufacturer will ensure proper functioning of the LEDs. Often they surpass this temperature which leads to an early failure of the LEDs.

Thermal switch selection:

A switch with 50°C cut off temperature was chosen. Though the usual junction temperature rated for LEDs are much higher, for the purpose of demonstrating the usage of KEMET thermal switches and having no datasheet of the LEDs, a junction temperature of 50°C was considered. Having a wide range of KEMET switches supporting different junction temperatures, it would be a matter of changing to a more suitable switch based on application.

Switch bounce:

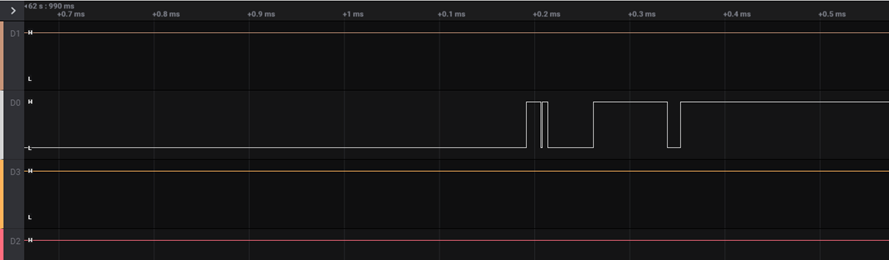

In this experiment, the thermal switches were used as a digital input to the MCU, based on which the corresponding block of code were executed. To avoid reading multiple values during switch state transition, the bouncing of reed switch contacts was checked using Logic Analyzer.

The bouncing was observed in the analyzer and the debouncing was done by the software.

Magnetic interference:

The switches being made of temperature-sensitive ferromagnetic substance, it's functioning can be influenced by external magnetic fields. Since the experimental set-up includes LED and no magnetic components, the effect of external magnetic fields is not being considered in this case.

The next blog would cover the implementation and outcome of the experiment.