Soft 404

There's a trick to deal with this type of wires:

This works easiest in a through-hole setting, but the capillary action also works in your setting.

When the mounting pad is as big as your example, a preheater can help, so that the little poor iron doesn't have to do all that heating by itself.

.

Sounds like the nickel plated kind. They really don't behave like normal stranded wire. You have to lure the solder in like the Pied Piper of Hamelin.

.

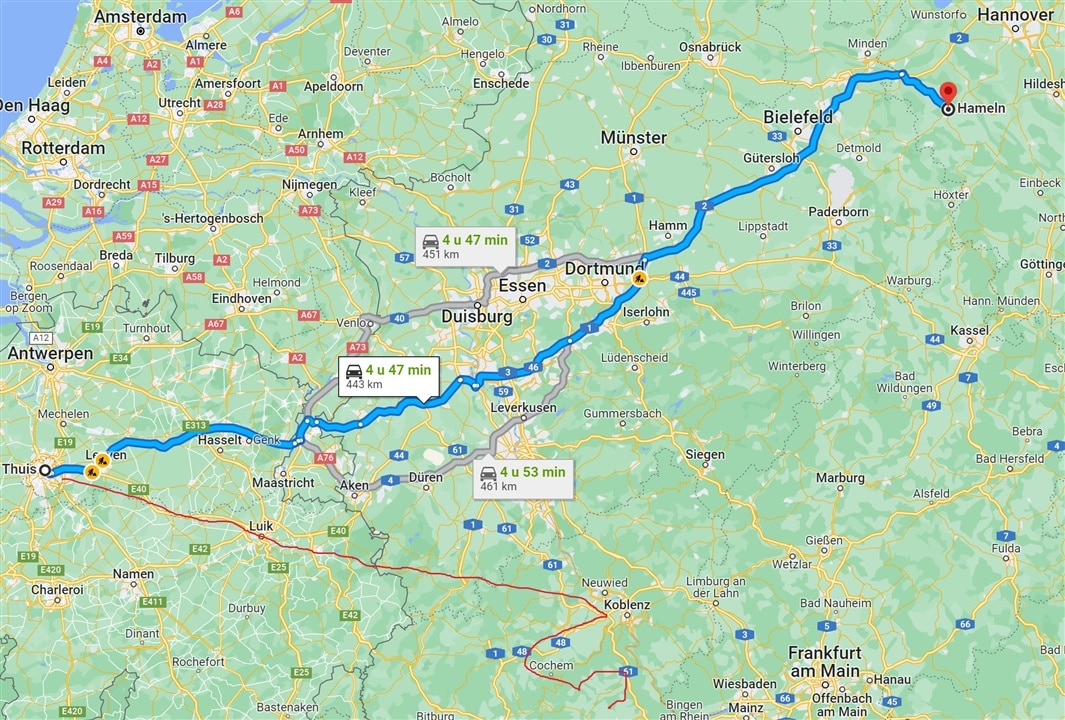

extreme off topic: Hameln isn't crazy far from here.

I drove half the distance a weekend ago (also to Germany, but a bit more south) to go watch volcanos and the Moesel and Rhine river with my <3. And served in the army not too far from there in cold war times.

I think the large copper plane is also taking up the heat from the soldering iron.

Just a small copper pad and a higher temperature may help. I would have tried scraping off the nickle from the wire before soldering. But the thermistor wires are too thin for that.

.

We now know Canada's nuclear code. Cold War PostIt

In scottiebabe's case, where a large copper plain is required, a preheater can do wonders.

When you use that, say to 120° C, the soldering iron has approx. 100° less to bridge.

A preheater makes life easier in general. And the value increases when you deal with large copper planes and lead-free.

If the PCB is traditional, thin trace only, then a preheater doesn't add. Other situations - be it with iron or air gun - it's a step up in solder comfort.

Additional win: it reduces the time you have to heat up components. For hybrid ICs that have an internal PCB (like the TI LM5XXX GaN FET), this can be the difference between success and failure. Hot-airing these too long will desolder internal connections in that type of IC.

Oh haha, I just noticed your post now, AFTER soldering them all... and yes I did run into some oddities. I found it was not too bad though, when I used my older paste type flux instead of the newer "no-clean" flux-pen. Maybe the older type of flux has a bit more bite to it

I was also just soldering to thin wires, so I guess it all got hot more quickly.