1 Drive the led

Normally, led can be driven with MCU directly, for some industrial MCU, 50mA can be achieved. But this is not applicable for this case ,since led in series leads to more power consumption and damage the MCU easily.

In fact, for most ports or pins, it shall be limited to 1mA to output

2 Drive led with arduino zero

2.1 Core Architecture & Key Hardware Features

2.2 Codes to drive the led

const int ledPin = 13;

void setup() {

// Initialize the LED pin as an output

pinMode(ledPin, OUTPUT);

}

void loop() {

// Turn the LED on (HIGH means 3.3V on Arduino Zero)

digitalWrite(ledPin, HIGH);

delay(1000); // Wait for 1 second (1000 milliseconds)

// Turn the LED off

digitalWrite(ledPin, LOW);

delay(1000); // Wait for 1 second

}

2.3 Arduino Zero Output Current Limits

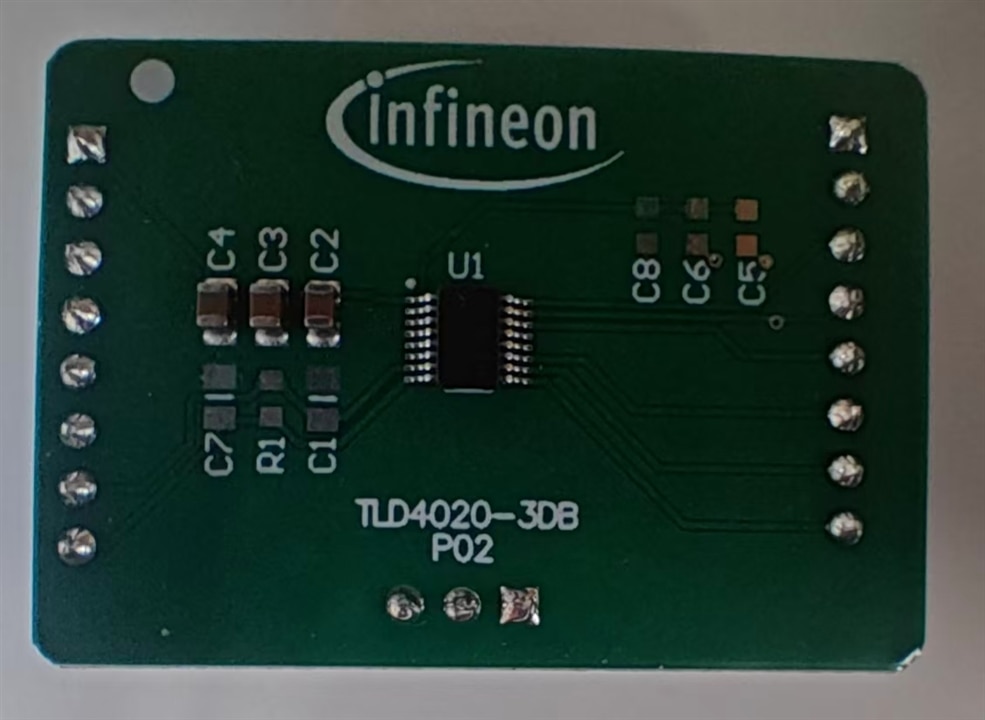

3 Introduction to TLD4020-3ET Chip

3.1 Core Architecture & Key Hardware Features

1.1 Microcontroller (MCU) Subsystem

1.2 On-Chip Memory

1.3 On-Chip Peripherals & Debug Support

3.2 LED Driver Capabilities

3.3 Communication Interface(Not used in this design)

3.4 Automotive-Grade Reliability & Compliance

3.5 Typical Applications

4 Summary

Here is some comparation of how to drive the led in this project.

Then, how to drive Würth Elektronik SMD size WL-ICLEDs would be more challenging. Of course , more interesting as well.