Table of contents

Abstract

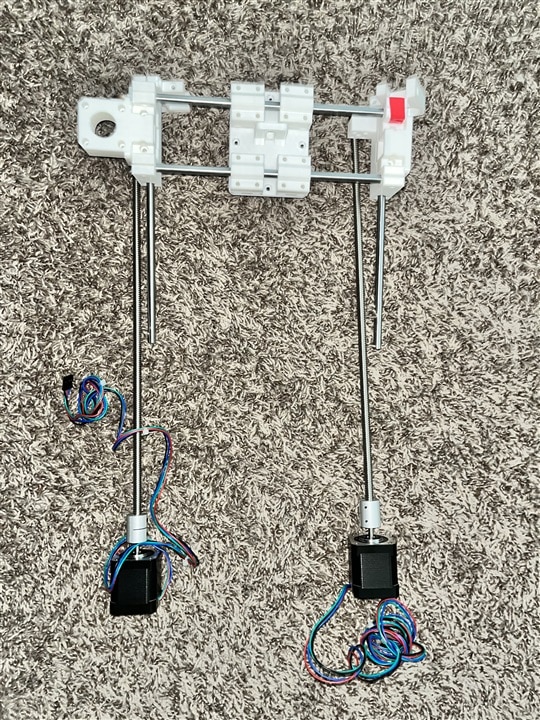

Building the frame for the project

Project

Project Genesis: Modifying the Green Mamba v2.0

Every great project starts with a solid foundation, and my DIY Pick and Place Machine is no exception. I began by repurposing the Green Mamba v2.0 DIY 3D Printer design as the structural blueprint for my machine. This versatile base provides an excellent starting point for creating a custom pick and place system.

Structural Components: 3D Printed Aluminum Extrusion Mounts

The frame came together through careful modification of the original Green Mamba design, with a focus on 3D printing mounts for 2020 aluminum extrusion. These precision-printed components allow for a robust and customizable frame that can be precisely adjusted to meet the specific requirements of a pick and place machine.

Axis Configuration

The machine's frame is built around three primary axes:

- Y-axis:

- 2 Guide Rails

- TX2 Pulley

- 1 Nema17 Motor

- X-axis:

- 2 Guide Rails

- TX2 Pulley

- 1 Nema17 Motor

- Z-axis:

- 2 Guide Rails

- 2 Lead Screws

- 2 Nema17 Motors

Challenges and Modifications

No DIY project comes without its challenges, and this build is no exception. I encountered a critical issue with the lead screws and T-nuts that required some creative problem-solving. The 400mm lead screw worked perfectly with the T-nuts, but the 200mm lead screw I initially purchased didn't align as expected.

Adaptation Strategy

- Identified mismatched lead screw dimensions

- Explored alternative mounting solutions

- Developed custom modifications to ensure precise axis movement

Next Steps in the Build

Electronics Integration

The next phase of the project involves:

- Wiring up the electronic components

- Configuring motor connections

- Calibrating the axis movements

Motor Programming

A critical step in bringing the machine to life is programming the motors to understand and navigate the X-Y-Z planes. This involves:

- Developing precise movement algorithms

- Calibrating step sizes and movement accuracies

- Ensuring repeatable and consistent positioning

Image Recognition Development

Looking ahead, the ultimate goal is to implement image recognition capabilities:

- Designing algorithms for component identification

- Creating a machine vision system

- Developing pick and place coordination code