Tuning Current for a Good amount of Torque

After making the linear pressing system with the 3D printed parts and stepper motor I was curious to check it with the foot pedal of the sewing machine. The pedal is not very easy to press and it requires a moderate amount of pressure to operate. It can be comfortably done with the foot but I was a bit afraid of whether my pressing mechanism is capable of moving it down or not. For checking it I placed the foot pedal at the bottom of the armature and started the motor. I was disappointed, it stops when the armature touches the pedal. After thinking for a few moments I got the idea of increasing the supply voltage. I removed the power adapter and connected a power supply to the TMC5272 controller board. I set the voltage to 12V and observed the current and it was only around 60mA while running the motor. I increased the voltage to 20V and this time motor was capable of pressing down the foot pedal as shown in the video below.

Though it worked I was not convinced to do it by increasing the voltage. I wanted to make it workable with 12V. So, I started reading the TM5272 datasheet again to find out whether it has any solution. The article "Setting the Full-Scale Current" on page 54 drew my attention. I got an equation for the RMS and Peak current.

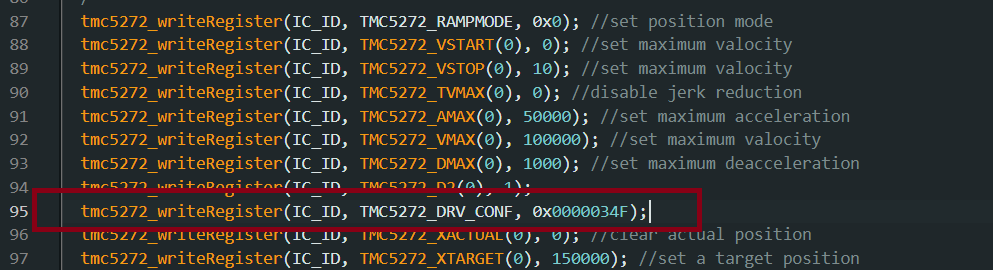

I came to know that by configuring the DRV_CONF register we can set the 100% current or less and the default current setting is not 100%. From the table 14 and 15, I found the required value for the DRV_CONF register for an expected current. I revisited the code and found that the content for four LSB bits is D (1101) which means FSR_Mx bits are 01 and FSR_IREF_Mx bits are 11 which allows a maximum 410mA for the motor. It should work but not!

Possibly the current was not bad for pressing the pedal but it was not working for any reason. I changed the contents of the DRV_CONF register and replaced D with F. F will allow maximum current (800mA) to the motor. I added the marked line in my main code inside the setup function with other configurations to write the value to the DRV_CONF register.

Surprisingly it worked and this time motor was capable of pressing the pedal very easily even from an 8V supply. Current flowing was also increased reasonably.

Making Connections Fixed

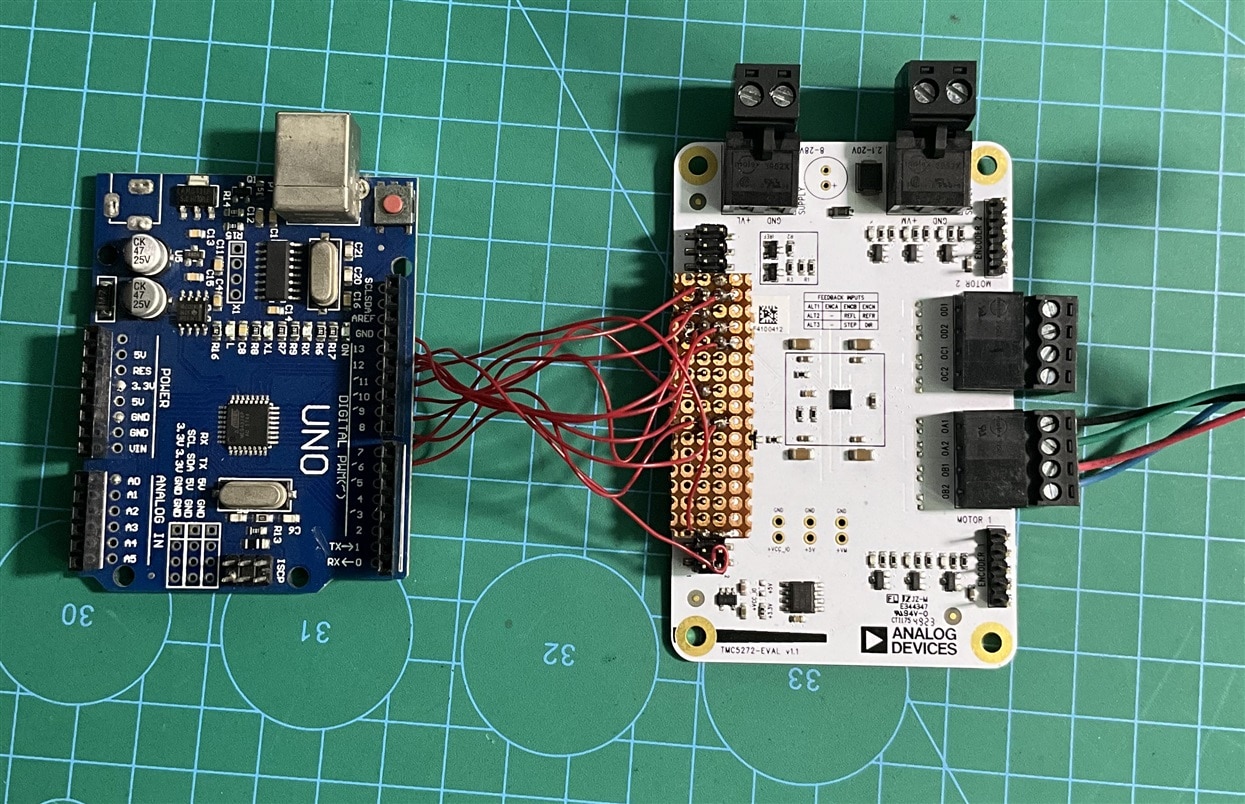

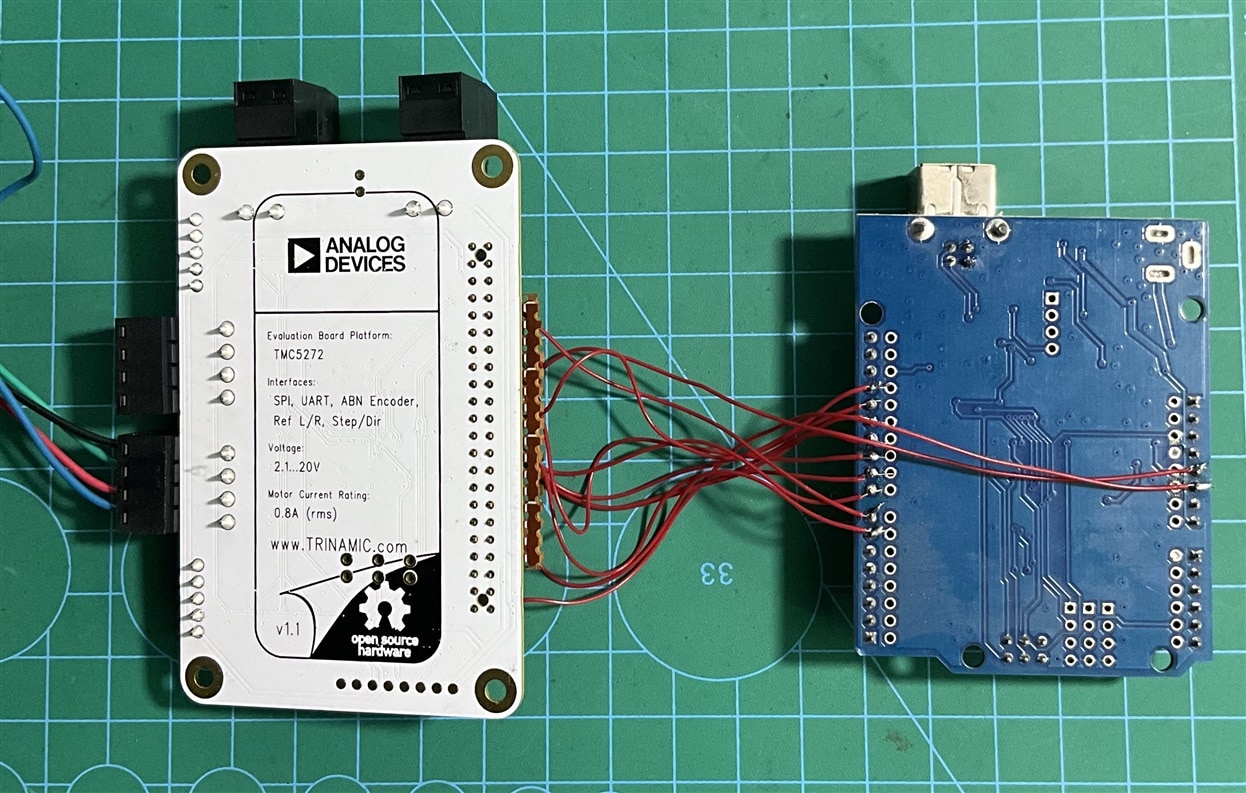

When I started this project I decided to use Landungsbrucke which came with the kit as the main controller of my project. I intended to write custom firmware to read the sensor and control the stepper motor accordingly. The Landungsbrucke board came with preloaded firmware that helps to control the TMC5272 Motor Controller board from TMCL IDE. This is an excellent way for testing and debugging. The most interesting fact is you can monitor and modify all the registers from the IDE. It helped me to clearly understand some of the functionalities of the TMC5272 motor controller. The Landungsbrucke MCU board is based on the GigaDevice Arm Cortex M4 microcontroller and I have no previous experience with GigaDevice MCU. So, I started with Arduino Mega and fortunately, I got a sample Arduino program for the TMC5272 motor controller from Analog Devices official GitHub link. I was able to run the code without any issues and it worked successfully. However, I faced some difficulties while modifying the code and I was able to successfully solve the issues with the help of TMC IDE. After solving the issues I decided to implement the code in GigaDevice Arm Cortex M4 microcontroller. I downloaded the Keil IDE and the required Add-ons for the Keil IDE for GigaDevice. I also downloaded the source code of the pre-loaded firmware. After a few hours of study and experiment, I realized it would be tough for me to implement the GigaDevice MCU within the limited time (I have 6 days only before the deadline). Even I don't have any GD-Link programmers and I am not sure whether ST-Link will work with the GigaDevice MCU or not. So, I changed my mind and decided to use Arduino UNO in my project. I removed all the connections with the Mega and inserted a double-line male pin header into the connector of the TMC5272 and then soldered with the Arduino UNO with jumper wires as shown in the images below.

I made the necessary pin change in my code and uploaded the code to Arduino UNO. It worked as expected.