In addition to the main Solar generation system, I am going to build a backup Hydro-Electric system in the year-round stream. Currently, it is the dryest part of the year and there is still a good amount of water flowing in the stream. From the water lines I can see in the stream it's going to get *much* higher in the winter months which should be more than enough for the turbine. I should be able to generate enough electricity from a turbine to offset the lack of sun in the winter.

The coolest part of hydro is that it generates 24h a day rather than the 5-6 hours of sunlight one might expect on Solar Panels. It's much less wattage, but running all night and day makes up for that.

I am not starting this project just yet, there are a couple more that need to be done first (keep an eye out for those as well), I just wanted to get the topic open so we can discuss.

This topic is open for discussion, I would love to hear your ideas and have you all involved. I will be documenting every step of the build here with descriptions, pictures and videos.

Why Hydro if I am installing Solar?

The solar array is going to be the main power generator. But during the winter months, it will generate much less than the summer months. I need a way to offset that. Many people run a generator for several hours every couple of days, or as needed. Since I am running a shop with CNC routers, welders, laser cutters, etc, I would need to run the generator quite often. And with gas prices around $6.70/gal right now, It's the most expensive way to generate electricity that I can think of. With the stream flowing all winter, It's a perfect opportunity to harness that potential energy to generate power.

Setting the Stage

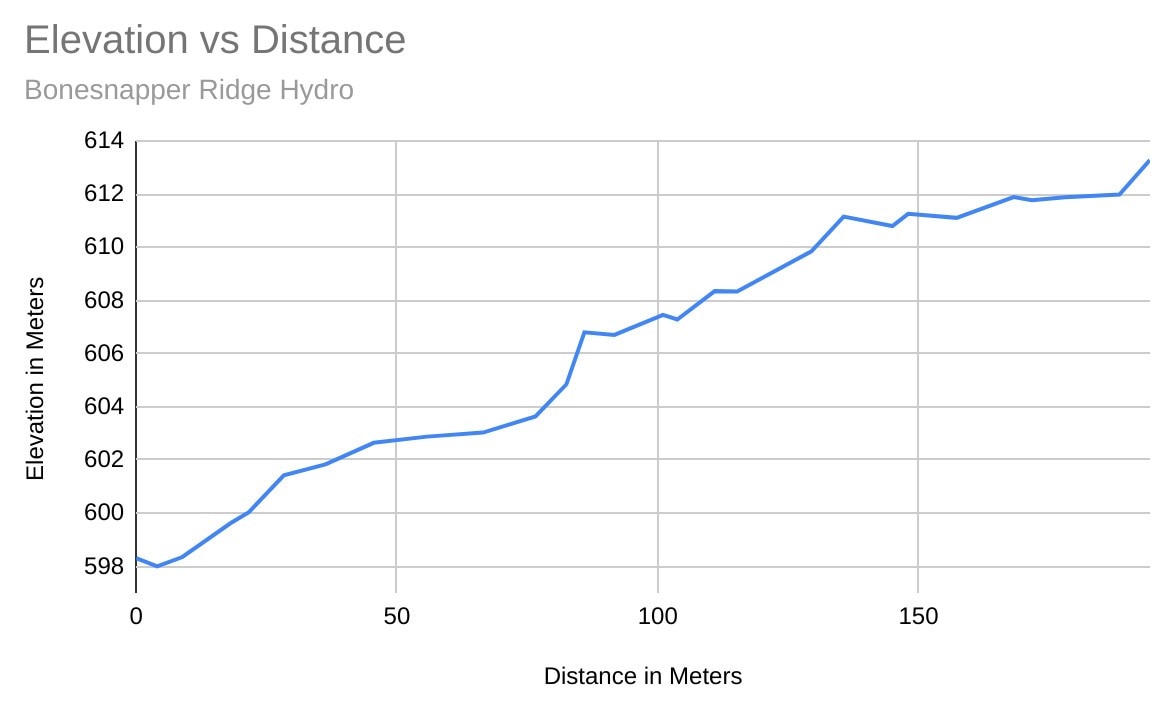

The stream runs through a large part of the property dropping in elevation. I walked the creek from the bottom to the top looking for good sites to collect water, and to place the turbine. The graph below shows the elevation & distance between these locations. Yes, it's in reverse, but I walked from bottom to top and did battle with google sheets and lost... Currently, it is October and the dryest part of the year in my area. There is still flow in the stream right now. Not much, but it is running. From observing (what I think are) the high water lines, it will have quite a bit of water flowing during the winter months.

As you can see, we get about 16m of elevation drop over about 200 meters in distance. I think this qualifies as a "low head" system. I won't know a GPM or L/S rate until it the rain starts, and I get a capture system in place.

I will also need to run a conduit from the hydro generation site up to the solar site since that is where all of the batteries will be.

The Current Plan

The current plan is to build some sort of intake system with filtration to filter out large debris and pipe that into a 50gal plastic barrel. The water will enter from the top of the barrel and exit about half way up the barrel in a 2" poly tube. The water will then run through approximately 500-700' of 2" poly tube to a motorized ball valve and then into the turbine distribution. The 2" pipe needs to be reduced to much smaller nozzles that shoot the water into the pelton wheel of the turbine. As beacon_dave suggested, I could also install motorized valves on each of the nozzles to control the amount of flow to the pelton wheel.

The Intake

The intake will divert water from the natural streambed into (probably multiple) 2" poly tubes. It will have to be constructed at a place in the stream where there is a small but dramatic elevation change. It could be as simple as cutting a plastic barrel at a diagonal and fitting it with 2" fittings. It will also have to have a screen to filter out large debris. I have seen some pretty clever methods for intakes. One was a rotating screen drum with catchment on the bottom 1/3rd. The rotating screen let all the large debris fall off back into the flowing stream.

The Barrel

Water flows into the barrel from the top, and exits in the center. This serves two purposes. First, it is another stage of filtration by having any heavy debris fall to the bottom of the barrel (I will have to have some sort of cleanout), and second, it removes any air in the line by having the water enter at the top, and exit at the center.

The 2" Poly Tube

This may be the most critical part of the system. The 2" tube needs to be as long as possible, and drop in as much elevation as possible to build up enough "head" to run the turbine. "Head" is the height measurement from where the water enters the system down to where it exits the system at the turbine. Combined with the amount of water flowing through the 2" poly tube we can calculate how much pressure will be in the tube, and even calculate how much power could be generated. This is a very simplified description of how this works and there are formulas for all of this which I do not understand yet but have a general idea.

The Turbine

I have looked into building my own, and that's not off the table, but there are off-the-shelf options available that are within the budget. If they are more efficient and can generate more power, that is going to be very attractive. Dont worry, there is plenty of other DIY in the rest of the system.

These systems typically use a Pelton wheel connected to a generator, with multiple reducer nozzles firing the water at the wheel from different angles. These are what I think of as a "side load" type of turbine. Another style which I have not investigated much yet, but supposedly works better for a "low head" are what I think of as a "top load" where the water falls down onto some sort of impeller to turn the generator.

The turbine type is all up in the air still. I have not decided on which type to buy, use, or build.

That is about all the information I have on this project so far. Please feel free to discuss this, I will be monitoring this blog and will try to respond to everyone.

-Kaleb

-

beacon_dave

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

KalebTheMaker

in reply to beacon_dave

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

KalebTheMaker

in reply to beacon_dave

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children