In this element14 presents episode, Katie tackles the challenge of revamping a budget-friendly toaster oven and transforming it into a dependable resin-curing tool with precise temperature control. She begins by explaining her need for clear epoxy resin with specific curing requirements, as well as the dilemma she faces regarding temperature settings. Intrigued by the 'for best results' instructions and a desire to reduce the curing time, Katie turns to an economical toaster oven she found online. Although acknowledging its lower quality, she hopes to modify it for her purpose.

Watch the Video:

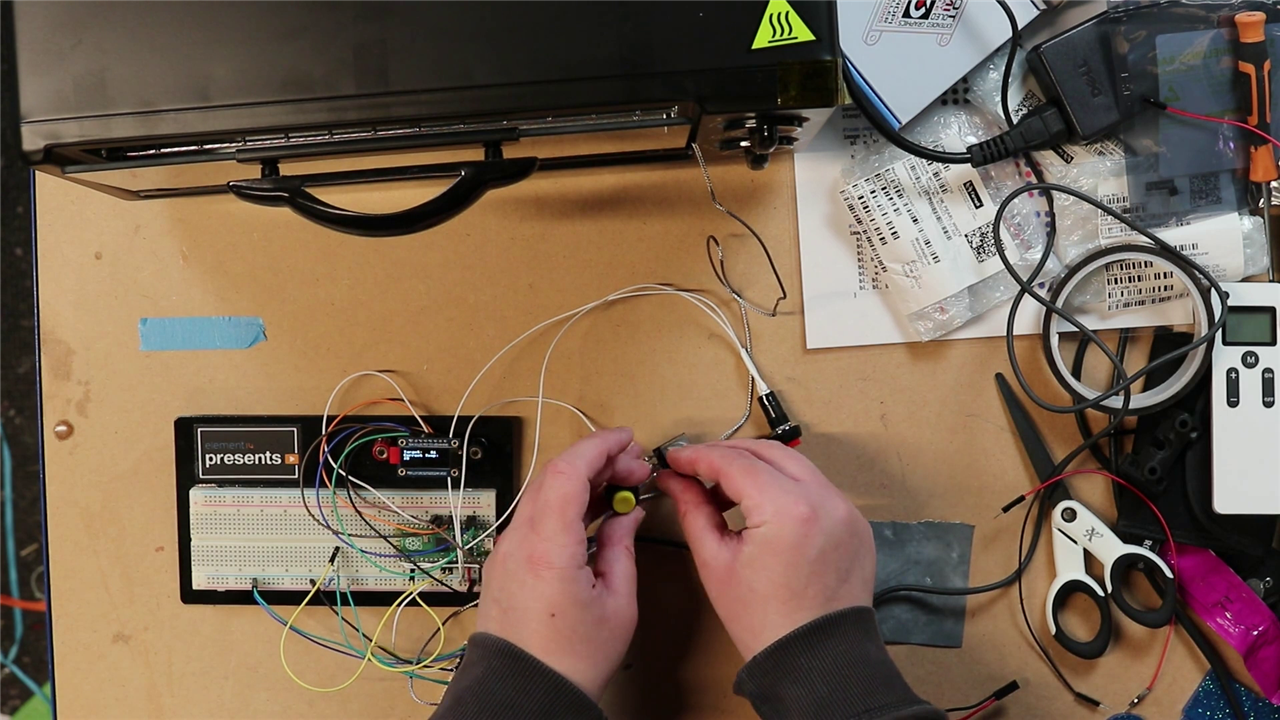

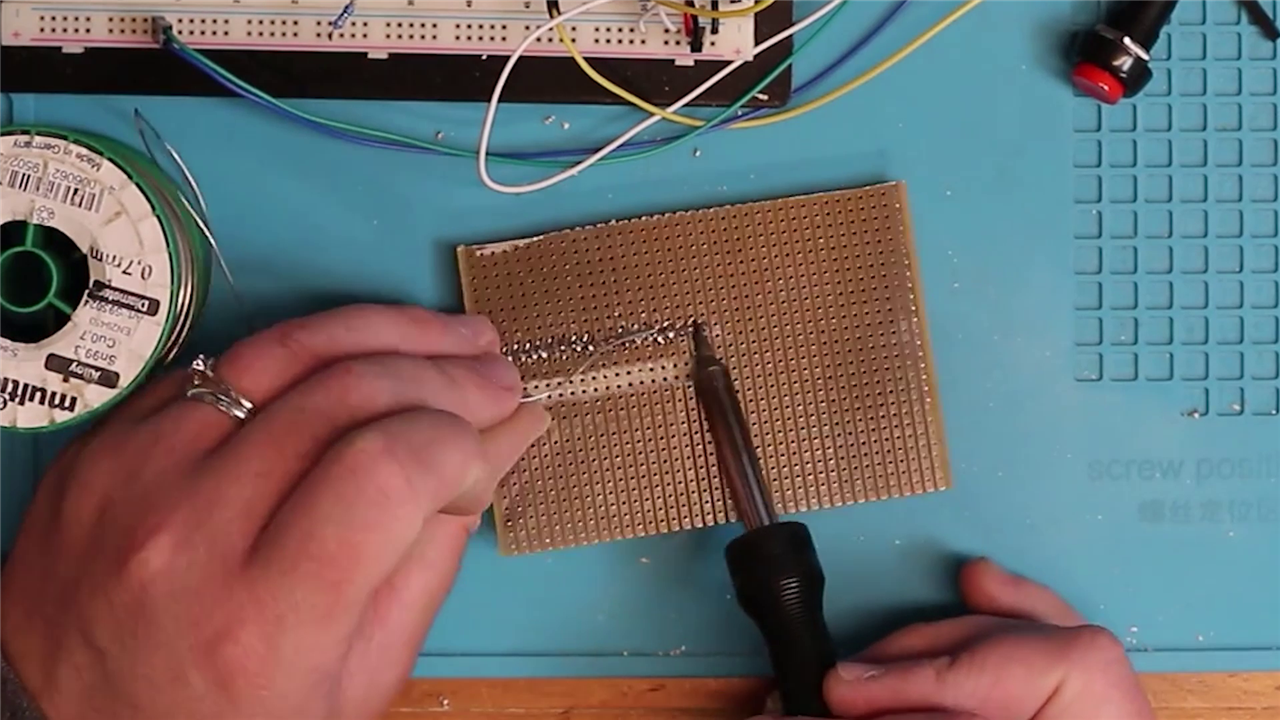

Katie's attention shifts to the toaster oven's temperature control mechanism, which she suspects might not accurately reflect the actual temperature output. The oven's operation involves adjusting the desired temperature and time, but Katie aims for more accuracy. To address this, she opts for a Raspberry Pi Pico and a spare thermistor. However, the thermistor's leads fall short of reaching outside the oven, necessitating soldering. Since the solder's melting point is near the curing temperature, Katie anticipates potential connection challenges.

The project's crucial stages encompass adapting a kitchen thermometer probe for precise temperature measurement and managing the oven's heating elements. Katie delves into the inner workings of the toaster oven, discovering the series connection between the timer and temperature control. She plans to replace the original control system with her design, integrating an Omron power relay to handle mains voltage switching. She acknowledges the requirement for a separate 24V power supply for the relay coil.

Constructing a detailed circuit and programming the Raspberry Pi Pico are fundamental steps in Katie's project. She successfully incorporates temperature readouts, buttons for setting and initiating oven functions, and a relay for heating element control. During testing, Katie observes that the temperature remains within a 10-degree range of the set value, marking a significant improvement over the original controller. Impressed with the results, she highlights the potential for wider applications beyond resin curing.

Subsequently, Katie addresses practical issues, such as preventing the K-Type thermocouple from coming into contact with grounded metal, which could disrupt temperature readings. She develops a protective insulation approach and further optimizes her control setup. Replacing loose connections with Wago block connectors enhances reliability and safety, mitigating grounding concerns. Throughout her journey, Katie demonstrates resourcefulness in troubleshooting and determination to create a refined and user-friendly DIY solution.

Ultimately, Katie successfully crafts a compact and functional control box for her toaster oven project. While acknowledging potential aesthetic improvements, she celebrates her accomplishment in developing a cost-effective and dependable tool for resin curing. She encourages fellow makers to explore this versatile modification, adaptable to various oven systems. Katie's experience showcases the potential of elevating everyday appliances with technical skills, while also addressing the challenges she overcame in achieving her goal.

Bonus Content:

Bill of Material:

| Product Name | Manufacturer | Quantity | Buy Kit |

|---|---|---|---|

| RASPBERRY PI PICO | RASPBERRY-PI | 1 | Buy Now |

| High Temperature Sensor, Gravity, I2C, K-Type, 800℃, for Arduino and Raspberry Pi Board | DFROBOT | 1 | Buy Now |

| Thermocouple, Nozzle, K, 0 °C, 350 °C, Stainless Steel, 6.6 ft, 2 m | LABFACILITY | 1 | Buy Now |

| GROMMET, BLACK M20 PK50 | PRO POWER | 2 | Buy Now |

| Power MOSFET, P Channel, 20 V, 4.2 A, 0.04 ohm, SOT-23, Surface Mount | DIODES INC. | 1 | Buy Now |

| Plastic Enclosure, Box, With Lid, Multipurpose, ABS, 83.1 mm, 177 mm, 120 mm | MULTICOMP PRO | 1 | Buy Now |

| IC, V REG +5.0V, 7805, TO-220-3 | ONSEMI | 1 | Buy Now |

| Power Relay, SPST-NO, 24 VDC, 10 A, G2R Series, Through Hole, Non Latching | OMRON ELECTRONIC COMPONENTS | 1 | Buy Now |

Additional Parts:

| Toaster Oven |

Top Comments

-

michaelkellett

-

Cancel

-

Vote Up

+1

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

hifromkatie

in reply to michaelkellett

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

rmd6502

in reply to hifromkatie

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

rmd6502

in reply to hifromkatie

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children