As technology providers or innovators search for an answer to climate change, electric vehicles (EVs) have emerged as a promising solution for reducing both greenhouse gas emissions and air pollution. Because of recent developments, they have become widely accepted as a means of transportation. Although EV sales have increased year-to-year, the construction of a nationwide EV charging infrastructure has lagged, which impacts consumers' concerns regarding their EV's maximum driving range. Additionally, the rapid development of EV technology has spurred research into new battery chemistries that aim to enhance range, charging speed, longevity, and safety standards. This learning module focuses on EV batteries, the current state of EV charging infrastructure, and the challenges associated with its development, as well as featuring an affordable solution that enables charging and remote monitoring of EV charging.

Related Components | Test Your Knowledge

2. Objectives

Upon completion of this module, you will be able to:

- Describe the various types of rechargeable EV batteries

- Understand EV battery chemistry and the charging process

- Discuss the challenges of EV charging infrastructure

- Explain the types of EV charging stations available

3. Basic Concepts

- 1.1 Basics of EV Batteries

A typical battery module comprises several cells connected in series, parallel, or series-parallel configurations. The cell is the central and most crucial component of an electric vehicle (EV) battery, as it determines the overall performance of an electric vehicle. The capacity of a battery is measured in kilowatt-hours (kWh). The higher the capacity, the more miles the car can travel without recharging. The lifespan of an EV battery depends on several factors, including how it is used, how deeply it is discharged, and the rate at which it is charged or discharged. These usage patterns have a direct impact on the battery's longevity. Higher temperatures can also accelerate battery aging. Another factor that influences battery life is cell chemistry, with different battery chemistries exhibiting varying characteristics related to aging and self-discharge.

- 1.2 Different Types of Rechargeable Batteries

Various cell chemistries are available on the market today:

- Nickel-Cadmium (Ni-Cd) batteries have higher performance than lead-acid batteries in terms of weight, specific energy, specific power, and energy density. However, they are no longer used in EV applications due to their high cost, memory effect, high self-discharge, and environmental concerns related to cadmium toxicity. Despite these factors, Ni-Cd batteries have a relatively long cycle life, meaning that they can be charged and discharged many times (approximately 2000-2500) before their performance significantly degrades. Ni-Cd batteries are resistant to overcharging and over-discharging, which helps prolong their lifespan and enhances their safety. Ni-Cd batteries also have certain limitations. One major drawback is their relatively low energy-density compared to newer battery technologies. Ni-Cd batteries have been largely replaced by other rechargeable battery technologies such as nickel-metal hydride (Ni-MH) and lithium-ion (Li-ion) batteries.

- Nickel-metal hydride (Ni-MH) batteries are rechargeable batteries that use a combination of nickel oxide hydroxide and a hydrogen-absorbing alloy as the active materials in their electrodes. They offer higher energy-density than Ni-Cd batteries, yet generate more heat during charging and typically have a 50% higher self-discharge rate than Ni-Cd batteries.

- Lead-acid batteries have been used for many years in vehicles and have proven to be a reliable and cost-effective energy storage solution. They are known for their low cost of production, wide availability, and ease of recycling. Lead-acid batteries offer a relatively low energy-density compared to other battery technologies, which means they can store a limited amount of energy per unit of weight or volume. In EVs, lead-acid batteries are used as auxiliary batteries due to their affordability and low self-discharge rate.

- Lithium-ion batteries (Li-ion) are currently the preferred choice for EV applications, and are known for their high-power density, long lifespan, and low self-discharge characteristics. They offer an excellent balance of performance, safety, and reliability. Graphite is commonly used as the anode (negative electrode) in lithium-ion batteries, while the cathode (positive electrode) can be made from a variety of materials. There are seven major types of cathode materials, including Lithium Cobalt Oxide (LCO), Lithium Nickel Oxide (LNO), Lithium Nickel Cobalt Aluminium Oxide (Li-NCA), Lithium Nickel Manganese Cobalt Oxide (Li-NMC), Lithium Manganese Oxide (LMO), Lithium Titanium Oxide (LTO) and Lithium Iron Phosphate (LFP). Figure 1 depicts a Li-ion EV battery module.

Figure 1: Li-ion EV Battery module. Image Source: Gereon Meyer/Wikimedia Commons

- Solid-state batteries are a significant breakthrough in battery technology. Unlike lithium-ion batteries, solid-state batteries use solid materials for both the electrolyte and the electrodes, providing benefits such as increased safety, higher energy-density, quicker charging times, and enhanced thermal stability. In solid-state batteries, sulfide superionic conductors allow for fast ion transport. They have exceptional thermal stability and can sustain high temperatures without sacrificing performance or safety. Solid-state batteries can charge at remarkable speeds. Solid-state batteries hold tremendous potential, however, there are still significant challenges that must be overcome before they become available on EVs. The Solid-State Batteries Tech Spotlight sheds more light on the development of solid-state batteries.

- Supercapacitors (aka ultracapacitors or electrochemical capacitors) are energy storage devices with different method of operation and performance than traditional batteries. While batteries store energy through chemical reactions, supercapacitors store energy electrostatically. Supercapacitors consist of two electrodes separated by an electrolyte, which can be a polarized liquid or a solid material. This design allows them to store energy through the liquid's polarization or the accumulation of ions at the electrode-electrolyte interface. Supercapacitors offer rapid energy storage and release capabilities, making them valuable for high-power burst applications.

Among the various types of batteries, lead-acid batteries, nickel-based batteries, and particularly lithium-ion batteries play prominent roles. Li-ion batteries have gradually replaced lead-acid and nickel-based batteries due to their superior key performance indicators (KPIs), such as energy storage capacity, fast charge rate, and low maintenance requirements, as well as their enhanced safety features. Lithium-ion batteries are expected to dominate the EV market at least through the next decade, serving as the primary power source for transportation.

- 1.3 Design and Construction of Lithium-ion EV Batteries

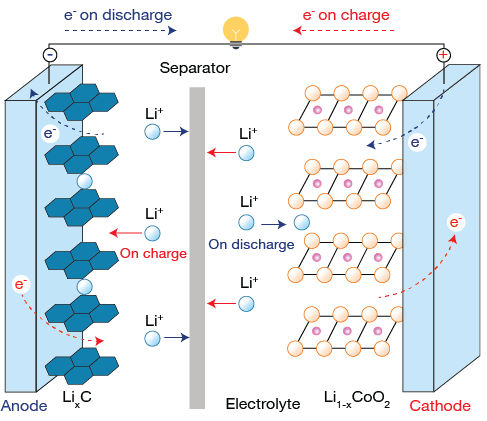

A Li-ion battery cell consists of three main components: the anode, cathode, and electrolyte (including separator). Figure 2 illustrates a typical Li-ion battery cell, where lithium ions move between the two electrodes during the charging and discharging processes.

Figure 2: Schematic of a lithium-ion battery cell. Image Source: sciencedirect.com

The anode typically consists of a graphite-based material that can intercalate lithium ions during charging and release them during discharging. The cathode, on the other hand, commonly contains a lithium metal oxide compound that can accommodate lithium ions during charging and release them during discharging.

The electrolyte is the medium that allows the movement of lithium ions between the anode and cathode. It is usually a lithium salt dissolved in an organic solvent. The separator is a porous membrane placed between the anode and cathode, preventing direct contact and short circuits while allowing the flow of lithium ions.

- 1.4 Battery Management System (BMS)

To maximize a battery’s lifespan, EVs use battery management systems (BMS) for controlling and monitoring charging and discharging, ensuring the battery is operating within safe limits, and achieving optimum performance over the life of the battery. Functions performed by a BMS include monitoring, measuring, calculating, communicating, control, and balancing, considering factors such as charge, temperature, voltage levels, and cell balancing.

The EV Battery Life Expectancy Tech Spotlight contains more details on Battery Management Systems.

- 2. The Challenges of Charging EV Batteries

The current state of EV batteries and their charging poses significant challenges that can prevent their widespread adoption. Key challenges include lack of charging infrastructure, long charging times, grid capacity, standardization, energy demand balance, and battery degradation. Automakers, infrastructure providers, governments, utilities, and stakeholders will need to work together to address these challenges. EV charging infrastructure, often referred to as electric vehicle supply equipment (EVSE), is a core component of a healthy EV ecosystem and requires substantial planning and dedicated electrical infrastructure at various levels of the distribution grid.

- 2.1 EV Charging Infrastructure

Utilities must make significant investments in charging infrastructure to ensure the grid can handle the increased electrical load. The Electric Vehicle Charging Infrastructure (EVCI) encompasses a variety of power distribution and control elements necessary for safely delivering power from the grid or local generation resources to the EV battery. These components typically include EV charging stations, electric grid interconnection components, power inverters, surge protection devices, circuit breakers, and loadcenters.

- 2.2 EV Charging Stations

Charging stations comprise a set of power electronics supplying regulated and safe power from the grid to the battery in the EV. Charging stations are generally wall or pedestal mounted. Several types of chargers are available, providing different current and voltage levels as required to meet vehicle-specific battery requirements. The power handling of EV chargers ranges from as low as 500 W to a high of 500 kW. It is predicted that improvements in battery chemistry will enable even higher charging rates in the future. Many EV owners do not have access to private or dedicated parking with charging capabilities and rely on publicly available charging options. The current charging infrastructure is classified into the following categories:

- Residential: Residential charging provides with a convenient and cost-effective way to keep an EV powered up and ready to go. Home charging is typically done using a residential charging station or an EVSE that is installed in your home. These are designed to charge EVs safely and efficiently from a standard electrical outlet or a dedicated charging point.

- Public: This category includes EV charging stations in publicly accessible areas or along highway corridors. Any driver can use public charging infrastructure, although some stations may have certain qualifications or restrictions. For example, some stations may be accessible to the public only after business hours or require payment through a specific application. Additionally, stations reserved for business patrons, such as hotel guests, museum visitors, or retail store customers, are classified as public restricted access.

- Retail Spaces: Retail spaces often offer AC charging stations with power up to 7 kW per charging port. These charging stations are suitable for slow charging sessions and are commonly found in parking lots or garages of shopping centers, supermarkets, and other retail establishments.

- Workplace: This category refers to EV charging stations intended to provide charging options for employees during the workday. Workplace charging infrastructure is typically accessible only to employees of a specific business and is therefore classified as private station. Similar to retail spaces, workplace charging stations typically offer AC charging with power up to 7 kW per charging port.

- Commercial/Fleet: EV charging stations in this category charge electric fleet vehicles. Municipal or private fleets, car-sharing services, and transportation network companies generally draw power from these stations. Fleet charging infrastructure is classified as private.

- 3. Types of EV Charging

The two main types of charging equipment for electric vehicles (EVs) are AC chargers and DC chargers. AC power that is fed into the vehicle needs to be converted to DC to charge the battery; this conversion needs to take place either inside the vehicle using an onboard charger (OBC) or inside the charge station. In both cases, the AC power is rectified using a PFC (power factor correction) stage to improve power efficiency and reduce harmonic distortion. PFC helps align the current drawn from the electrical source with the voltage waveform, making the charger more efficient and reducing strain on the power grid. AC charge points rely on the vehicle’s onboard charger to rectify and boost the supply to as much as 800 VDC to charge the vehicle’s battery. An OBC enables a vehicle to be charged directly from a standard home plug (slow AC) or from a specialized AC charger (moderate AC) at a home, workplace, or public location.

AC chargers are typically categorized into Level 1 and Level 2 chargers for home charging. Level 1 chargers are slower, using a standard 110VAC household electrical outlet and charging at a rate of 1 kW to 3 kW per hour. They provide roughly five miles of driving distance per hour of charging. Level 2 chargers, on the other hand, require a 240VAC on a dedicated circuit and can deliver power in the range of 7 kW to 22 kW. They provide 12 to 80 miles of driving distance per hour of charge.

Chargers that provide direct current to the vehicle battery and bypass the onboard converter are referred to as DC chargers or DC fast chargers. They are also called Level 3 chargers due to their ability to provide higher charging rates. A DC charger bypasses the OBC's AC/DC conversion stage and supplies DC directly to the vehicle's battery management system. DC charging is classified as either rapid or ultra-rapid depending on the amount of power delivered. The output starts at around 50 kW (rapid) and can reach 350 kW (ultra-rapid).

A commercial DC charger performs many of the same tasks as an AC charger. The main difference is in the charging path, which now provides high-power DC to the EV. The higher power delivery requires a 2-phase or 3-phase AC feed; this is converted to a DC charging signal by an AC/DC power supply. Isolation is also required in both DC and AC chargers. Table 1 lists the various specifications of Level 1, 2, and 3 chargers.

| Charger type | Supply voltage | Phase | Type of use | Energy supply interface | Power level | Charging time |

|---|---|---|---|---|---|---|

| Level 1 | 120V | 1 phase | Charging at home or office | Conventional outlet | 1.4 - 1.9 kW | 17 Hours |

| Level 2 | 240 V | 1 or 3 phase | Charging at private or public outlets | Dedicated chargers | 3.1 - 19.2 kW | 8 Hours |

| Level 3 | 300 - 600 V | 3 phase | Charging at station | Dedicated chargers | 50-240 kW | 30 minutes |

Table 1: EV charger type classifications. Image Source: doi.org

EV chargers also include control and monitoring circuitry, such as microcontrollers (MCUs) and digital signal processors (DSPs), that control and monitor various aspects of the charging process. These devices manage the charging rate, monitor battery voltage and temperature, and ensure safety features are functioning correctly. Other safety features include surge protectors or circuit breakers. Many chargers have built-in communication interfaces such as CAN (Controller Area Network) or Ethernet to facilitate communication between the charger and the electric vehicle. These enable features such as data exchange, vehicle identification, and control commands.

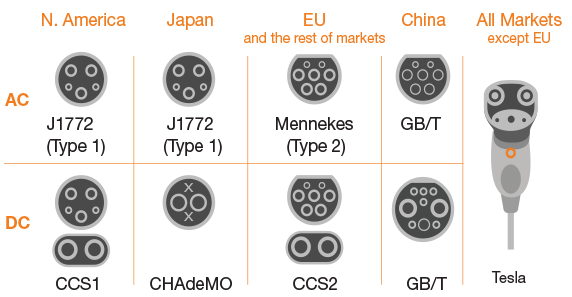

EV Connector Types

EV supply equipment often supports more than one connector type. It is common to find charging points that have more than one connector cable per charging point. CCS1 (Combined Charging System, Type 1) is a North American standard; CCS2 (Combined Charging System, Type 2) is a European standard; CHAdeMO is a standard that began in Japan and has been adopted mostly by Asian countries. CCS1 (IEC 62196 Type 1) and CCS2 (IEC 62196 Type 2) connectors have two dedicated DC contacts to allow high-power, fast charging at up to 350kW. Figure 3 depicts the various EV connectors used worldwide for AC and DC charging.

Figure 3: Depiction of different AC and DC EV connectors. Image Source: evcharging.enelx.com

Standards Governing EV Charging Station Design

It is essential to establish standardization and regulations to ensure the safety, reliability, and interoperability of EV charging infrastructure and battery systems. Table 2 lists the key standards for EV charging. These standards ensure compatibility and safety across different EV charging stations and vehicles, allowing for seamless charging experiences and promoting the widespread adoption of electric vehicles.

| Standard | Description |

|---|---|

| IEC 61851 | Defines the charging system architecture and communication protocols for EV charging infrastructure. |

| IEC 62196 | Specifies the charging connectors and cables used in EV charging systems |

| IEC 60364 | Addresses electrical installations in buildings, including the requirements for EV charging infrastructure |

| ISO 15118 | Focuses on the communication between electric vehicles and charging stations |

| UL 2202 | Covers the safety requirements for EV charging equipment |

| SAE J1772 | Defines the electrical connector interface and communication protocol for Level 1 and Level 2 AC charging |

| CCS (Combined Charging System) | A standardized DC fast charging system for electric vehicles, combining AC and DC charging capabilities into a single charging connector |

Table 2: List of key standards related to EV charging

4. Analysis

Eaton's Solution for EV Charging

Eaton chargers are designed to provide real-time energy insights and seamlessly integrate with onsite renewable and energy storage systems. This integration enables the development of intelligent and environmentally efficient energy systems to fulfill existing and future demands. Eaton EV chargers are affordable charging solutions, providing sustainable mobility in a variety of settings, including homes, offices, and other commercial venues. Eaton EV smart breaker chargers, part of Eaton's smart energy offerings powered by Brightlayer, provide simple interaction with a variety of software platforms.

Some of the features of Eaton EV chargers include:

- Efficient and simple installation enabled by circuit breaker form factor.

- Charging schedules can be set to optimize costs

- The EV Charger Manager app can receive alerts and notifications.

- Control rate of charge with revenue-grade metering accuracy.

- Real-time and remote access allows you to set and change charging times.

- 4.1 Green Motion EV Smart Breaker Charger

Eaton's Green Motion EV charging design combines fast AC charging, metering, and remote access within the traditional footprint of a circuit breaker. The small form factor allows the charger to either be mounted in the form of a wall charger or single/dual port pedestals based on where the car is parked. The EV Smart Breaker Charger contains integral solenoid-controlled contacts in series with QUICKLAG thermal-magnetic breaker. Its advanced metering delivers comprehensive insight into energy usage and enables homeowners to control essential and non-essential energy usage.

Eaton’s Green Motion EV Smart Breaker Chargers Support features such as:

- Energy savings and efficiency with ENERGY STAR® certification

- Fast AC L2 charging at 7.7 kilowatts with 240 VAC

- Highly accurate metering accuracy (+/-0.2%)

- Customization with open platforms—open APIs and Open Charge Point Protocol (OCPP) support

- Eaton’s EV Charger Manager app enables setting charging schedules to optimize costs, receiving alerts, and notifications

Figure 4: Eaton Green Motion EV Smart Breaker Chargers

The EV Smart Breaker Charger is intended for charging plug-in hybrid and all-electric vehicles and is compatible with the Society of Automotive Engineers’ SAE J1772 charging standard. In addition to traditional thermal magnetic protection, EV Smart Breaker Chargers are designed to:

- Protect from ground faults, providing automatic reset so no user interaction is needed

- Instruct the vehicle on how much current to draw to keep from overloading the circuit

- Protect users with interlocked power; power is never available at the connector unless it is plugged into an electric vehicle.

Table 3 lists the different variants of Eaton’s EV chargers.

| Green Motion EV Smart Breaker Chargers | Green Motion Building | Green Motion Building Pro | Green Motion Fleet | Green Motion Fleet Pro | Green Motion EV Charging Busway | ||

|---|---|---|---|---|---|---|---|

| Installs directly into Eaton loadcenters and panelboards1 | Residential, EV wall charger | Multi-family and workplace charging solution | Commercial, high-power charging for fleet applications | Commercial and destination charging solution for passenger vehicles | Fleet and Industrial charging solution for medium-duty trucks | Overhead EV charging for large fleet and industrial applications | |

| Max power rating | 32A/7.7 kW | 32A/7.7 kW | 40A/9.6kW | 48A/11.5kW | 80A/19.2kW | 80A/19.2kW | 80A/19.2kW |

| Metering accuracy | ±0.2% | ±0.2% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Enclosure | 2-pole circuit breaker | Plastic | Plastic | Plastic | Plastic | Metal | Metal |

| Communication protocols | Wi-Fi | Wi-Fi | Wi-Fi, Ethernet, cellular | Wi-Fi, Ethernet, cellular | Wi-Fi, Ethernet, cellular | Wi-Fi, Ethernet, cellular | Wi-Fi, Ethernet, cellular |

| Connector and cord | J1772 EV connector and 25-foot cord with patented LED design to indicate state | J1772 EV connector and 25-foot cord | J1772 EV connector and 25-foot cord | J1772 EV connector and 25-foot cord | J1772 EV connector and 25-foot cord | J1772 EV connector and 25-foot cord | J1772 EV connector and 25-foot cord |

| User interface | Status indicator | Status indicator | Display screen & status indicator | Touchscreen display & status indicator | Display screen & status indicator | Touchscreen display & status indicator | Status indicator |

| Mounting options | Integrates directly into panel | Wall and pedestal options | Wall and pedestal options | Wall and pedestal options | Wall and pedestal options | Wall and pedestal options | Busway |

| Access control2 | QR code | QR code | QR code & RFID | QR code & RFID | QR code & RFID | QR code & RFID | QR code |

| Payment capabilities2 | QR code, mobile app | QR code, mobile app | QR code, RFID, mobile app | QR code, RFID, mobile app | QR code, RFID, mobile app | QR code, RFID, mobile app | QR code, mobile app |

| Trade compliance | TAA | TAA | - | TAA | - | TAA | - |

| CTEP compliant | - | - | Yes | -3 | Yes | -3 | - |

| OCPP compliant (1.6J) | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Outdoor rating (NEMA3R) | - | Yes | Yes | Yes | Yes | Yes | - |

| Energy Star certification | Yes | Yes | Yes | Yes | Yes | Yes | - |

1. Install up to six EV smart breaker chargers

2. QR code, RFID card, and Mobile app provided by EV software provider

3. CTEP compliance: Building Pro and Fleet Pro will have CTEP compliance post launch

Table 3: Comparison of Eaton Green Motion EV chargers

- 4.2 Eaton Green Motion 50–150 kW DC Fast Charger

Figure 5: Eaton Green Motion DC Fast Charger

Eaton Green Motion 50–150 kW DC Fast Chargers are designed to provide fast charging for vehicles with 400VDC battery packs, such as the Ford Mustang Mach-E and Ford F-150 Lightning. Most EVs produced from 2010-2022 with lower voltage, 400V battery packs can take advantage of the fast charging. Green Motion DC Fast Chargers use passively cooled cables, eliminating the need for liquid cooling components in the charger or the cables themselves. This reduces maintenance, complexity, and cost requirements while improving reliability.

Installation Options

There are various options available to facilitate the installation of electric vehicle supply equipment (EVSE) in residential settings, including turnkey solutions. These solutions aim to make the process easier for homeowners by combining EVSE purchases with professional installation services. While the installation of EVSE is typically straightforward for homes with sufficient electrical service capacity, it can become more complex if an electrical service upgrade is needed. The different installation options available are:

- Direct connect kit: Installs directly in Type BR loadcenters or PRL3X panelboards close to where the EV is parked

- Direct connect + junction box kit: Includes a junction box to support greater distances between the EV and charger

- EV wall charger: Installs (hardwired) indoor/outdoor for additional versatility and a modern design

- EV wall charger plug-in: Installs indoor/outdoor and plugs into 240V receptacle for simple and quick installation

- Single & dual port pedestal: Option to mount one or two wall charger(s) on the EV pedestal to make charging more accessible in open parking areas

- EV multi-charger system: Installs directly in a BR loadcenter and can accommodate multiple EV smart breaker chargers

EVSE installation must comply with local, state, and national codes and regulations. Different jurisdictions may have specific requirements regarding electrical installations, building codes, fire safety, environmental considerations, and permits. Contractors must be familiar with these codes and standards to ensure compliance throughout the installation process.

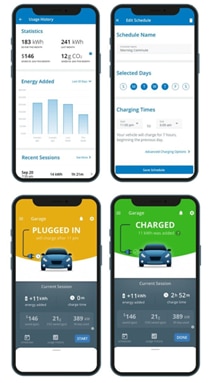

Charger Manager App

The Eaton EV Charger Manager app is available on both the iOS and Google Play stores. The app is capable of tracking energy usage and managing chargers, enabling users to save on energy costs by charging during off-peak hours. The app can also notify users about charging status, power outages, and ground fault conditions. Figure 6 shows the Charger Manager App with various features on the user interface.

Figure 6: Eaton Charger Manager app

Smart Breakers and Cloud Connectivity

Eaton's Wi-Fi smart breakers offer circuit protection, cloud connectivity, remote control, and accurate metering, all packaged in a standard miniature breaker form factor. Because of their standard form factor, installation is straightforward. They are OCPP 1.6J certified, enabling them to integrate seamlessly with your preferred charge management solution. Eaton smart breakers are compatible with most Eaton loadcenters. Leveraging cloud connectivity, they enable monitoring and control of various loads within the home, including electric vehicle chargers and energy storage systems.

Click here for more information about EV Charging.

5. Glossary

- Anode: the negative electrode in a battery where oxidation occurs. During oxidation, the anode loses electrons, which flow from the anode to the cathode, which is the positive electrode. The flow of electrons creates an electric current.

- Battery Management Systems (BMS): a system that manages a rechargeable battery. Functions include protecting the battery from operating outside its safe operating area, monitoring its state, calculating secondary data, and/or balancing it.

- Cathode: the positive terminal of the battery, which accepts electrons during the discharge or use of the battery.

- Circuit breaker: a safety device designed to protect an electrical circuit from damage caused by overcurrent by interrupting current flow. A circuit breaker can be reset (either manually or automatically) to resume normal operation.

- Electrode: a conductor used to make contact with a nonmetallic part of a circuit. In a battery, the electrodes allow for the flow of electric current into and out of the battery.

- Electrolyte: a substance that allows the flow of ions between the electrodes. The ions are charged particles that are created when the battery is charged or discharged.

- Energy Density: the amount of energy stored in a battery per unit mass or volume, measured in watt-hours per kilogram (Wh/kg) or watt-hours per liter (Wh/L).

- Intercalation: the process of inserting ions into a host material. In the context of battery operation, intercalation refers to the insertion of lithium ions into the host material of the negative electrode, typically graphite.

- Loadcenter: a panel that houses circuit breakers. Also known as a breaker box.

- Memory Effect: a phenomenon that can occur in some types of rechargeable batteries, where the battery's capacity decreases over time, even when the battery is fully charged.

- Power Inverter: an electronic device that converts direct current (DC) to alternating current (AC).

- Self-discharge Rate: the rate at which a battery loses its charge when it is not in use.

- Separator: a porous membrane placed between the anode and cathode, preventing direct contact and short circuits while allowing the flow of lithium ions.

- Superionic: a state of matter in which ions exhibit a great deal of mobility. A superionic compound has a great deal of electrical conductivity.

- Solid State Battery: a type of rechargeable battery that uses a solid electrolyte instead of a liquid or gel electrolyte.

*Trademark. Eaton is a trademark of Eaton Corp. Other logos, product and/or company names may be trademarks of their respective owners.

For more related products Shop Now

Test Your Knowledge

Automotive 1

Are you ready to demonstrate your EV charging essentials knowledge? Then take a quick 10-question multiple choice quiz to see how much you've learned from this module.

To earn the Essentials Automotive 1 Badge, read through the learning module, attain 100% in the quiz at the bottom, and leave us some feedback in the comments section below.

Top Comments

-

jelektro

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

jelektro

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children