Last week, e14phil from the element14 community invited me to see the Farnell office and warehouse in Leeds. The office is located next to the old warehouse near to the centre of town.

Once we were past the big security gates and guard post, I got a idea for the size of the operation. Not sure why I thought it would be a small office as it houses, marketing, purchasing, logistics and of course the community team along with the software developers who customise and tune the e14 website.

Phil provided me with a lovely lunch in the canteen although I was slightly disappointed to see I'd missed the "National Yorkshire Day" special. The dev team joined us as they were also getting the warehouse tour.

The warehouse is over the other side of town, tucked behind a couple of Amazon warehouses. It looks pretty big from the road but when you get closer you realise it is a lot bigger as the whole warehouse is down a steep bank and hence is a lot taller than first impressions. My estimates from google maps put it at over 100m wide and 250m long, and it's 5 stories tall.

Entrance is over a bridge which leads in on an upper floor, Phil tells me that the ditch and bridge is to keep the zombie apocalypse out and it does seem to be working as there were no zombies anywhere near at the time of the visit, although it was a very sunny day.

After security checks were complete we were met by our guide, Richard. He provided us with anti-static shoes and a high visibility vest. A flight of stairs led up to a viewing balcony where we got to see the massive size of the warehouse.

Richard explained each of the areas and then took us down to see them in closer detail.

The side of the warehouse has some very large doors where trucks unload the palleted deliveries.

Once unwrapped the components are reviewed for quality and then placed into plastic tubs called totes. Smaller components are divided into smaller boxes and big items such as power tools or test equipment are placed onto pallets for storage on racking.

Intake also handle customer returns so have benches for repackaging and inspection. Cut tape can be re-reeled here to ensure it runs through pick and place machines without issue.

Sensitive components are placed ovens for removing moisture before being stored in vertical rotating shelves that are several floors tall.

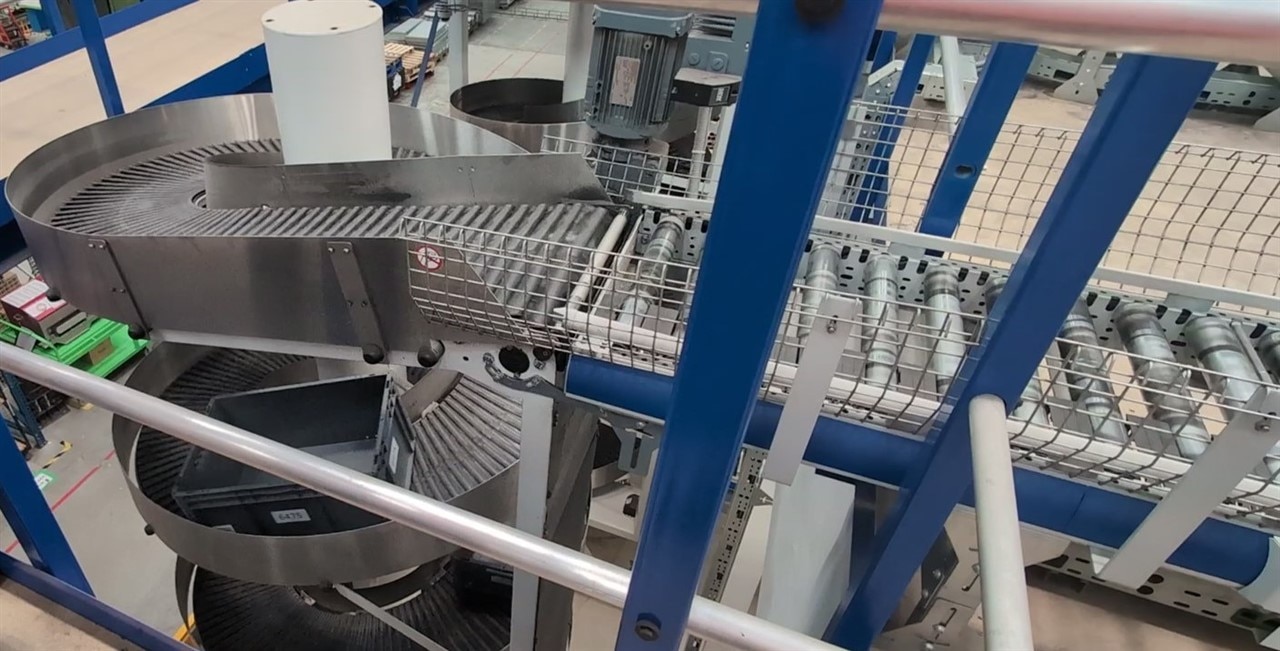

The totes are placed onto conveyors for automatic routing to the right part of the warehouse. These are all controlled with industrial controllers such as PLCs and vision systems. Optical sensors read the barcodes on the totes and check the passage of the totes as they move around the system. Overhead cameras inspect the contents.

| {gallery}Totes |

|---|

|

Curved Conveyor: A roller conveyor going around a corner with lots of totes in the background |

|

Camera: An overhead camera and barcode scanner down below |

|

Ramps: Totes going up a ramp to a higher level |

|

Helter-skelter: A spiral conveyor to send the totes down several floors at once |

When an order comes in from a customer the process of collecting together the right parts is called picking. And picking is split up based on the type of the part.

Automated picking is possible for many components and the totes and conveyors bring the products to the picker. An overhead system shines a red light on the items to be picked and a screen displays the quantity.

Items such as reeled SMD components are manually picked by team members with arm mounted computers and trollies with inbuilt step ladders. Small parts are placed into boxes filled with anti-static foam or into anti-static bags.

Items requiring special processes such as crimps and kits are sent to a slow pick area. Where they can be processed without disrupting the flow of orders in the main areas.

For some components such as Xilinx FPGAs dust is a serious concern. So a special low dust, anti-static room is used to store these.

Down the far end of the warehouse, wire can be ordered by the meter and a fleet of electric forklifts get the bigger items from the high storage.

Once an order is complete it is sent over to packaging. Here's it is placed into a bag or box depending on the size and labels are created for the couriers. International orders are consolidated into big 1m³ sized boxes for local despatch in the destination country.

One interesting feature was the ability for people to schedule their deliveries for invoice on despatch, this allows companies and engineers to manage their own stock levels and cash flow.

The volumes of orders are fairly steady but there are busy times around new Pi launches and end of year in July.

Thanks to Phil for organising and Richard for providing the tour.

Top Comments