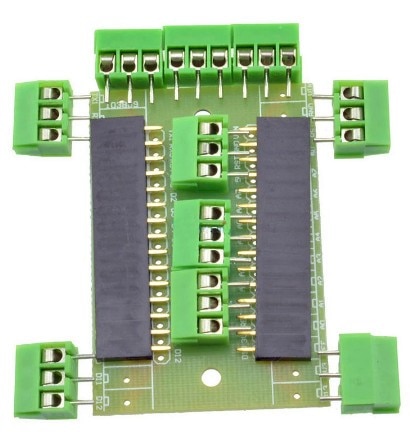

I’ve purchased the Arduino Nano holders above in the past for projects.

I have gone one step further and created PCB’s to hold a Nano and a JQ6500 sound module. I can share the KiCAD files if someone is interested. I reluctant to post them until I can improve the quality.

The ellipses shown on the boards proves that just because you can find a KiCAD footprints doesn't mean it is right. The ellipses on the left shows bow-legged pins because the footprint was wider than the actual module. The foot print dimension for the ellipse on the right were also off by 2.54mm. Live and learn.

After baring witness to Shabaz PCB design, I thought what would the E14 Community put as the bare minimum on a project board. I agree "it depends on what you want to do on the board." But I'm thinking there would be some general support even before the project starts. Things like power, protection, options.......

In the above project example. There is power I/P. I included a diode to prevent computer power feeding back into the power supply. I'm thinking maybe a 5V power supply. My design has the JQ6500 being supplied by the Nano. The example above uses 12VDC I/P. The 5V PS used in Shabaz design would be great on this board. Note my design doesn't have any filter capacitors that are see on other PCB's.

I'm currently working on a single Nano multi-function animation PCB. The board would have option to support light, sound and motion. The light would be LED's, the sound is the JQ6500 module and the motion would be some type of motor control. I'm currently thinking 5V servo but that is expanding. The board above supports a MOSFET module to drive a 12V load. There is a input to trigger the Nano with a button and speaker pins.

I'm trying to get the model railroad community I play in, interested in microcontroller animation. If there was a small inexpensive PCB that allowed them to dabble in Arduino code to create simple animations, Lights coming on in a building. a car horn honking or a door opening on a building (i.e. light, sound and motion) maybe it would generate some interest.

I'm curious what are your bare minimums for a Arduino project type board?