|

I'm writing a flow to automate long-term temperature measurement.

|

Test Setup

Setup:

- Keithley DMM6500

- Keithley 2000-SCAN 10 channel scan card

- K-type thermocouple

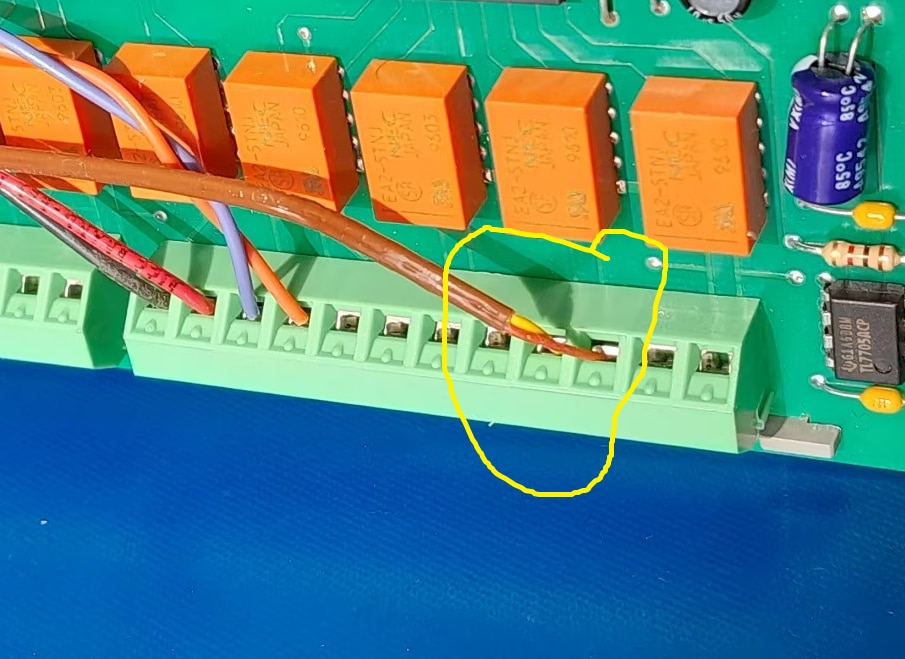

a thermocouple in channel 2. Note: wires are wrong way in this phote

Software:

- a SCPI script that I write in this blog

- Keithley Communicator

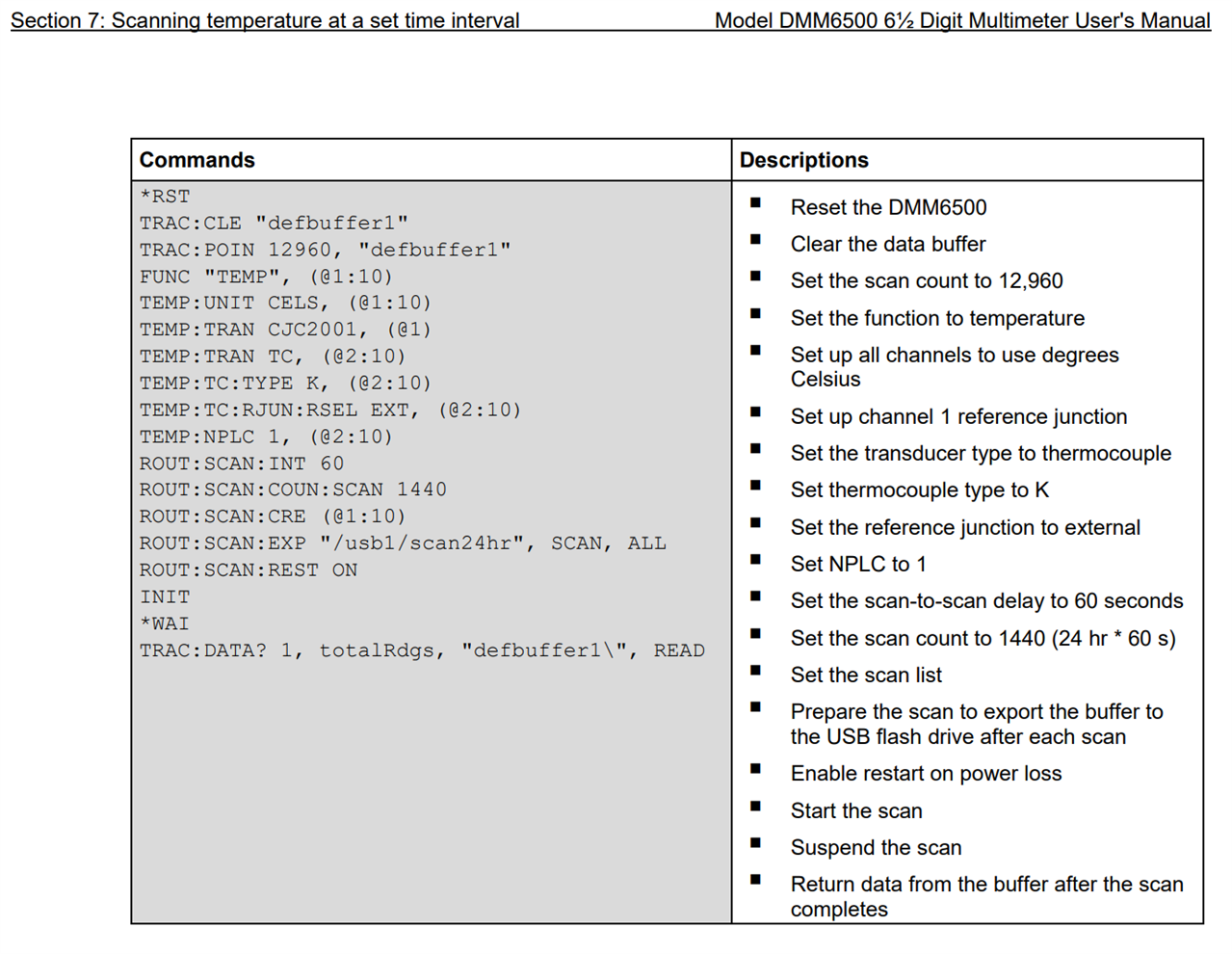

The start is humble. It's Keithley's example adapted to simulated cold junction temperature mode.

In that mode, you "hard code" the temperature of the area where the thermocouple is connected to the scanner card.

I've defined the script to scan channel 2 and 3 - even though nothing is connected to channel 3. It will overflow.

I sample 2 channels to learn myself how to do multiple measurements. In hindsight, I should have bridged CH2 and 3 on the card, so that I'd have valid measurements.

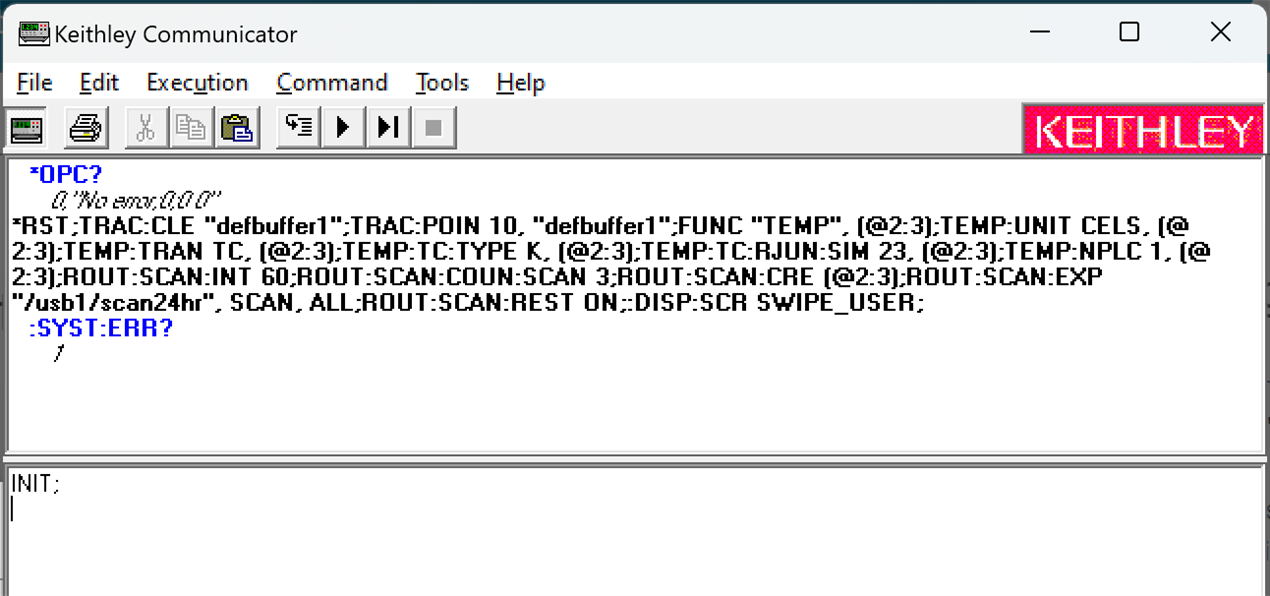

The Keithley SCPI test app, just before starting the scan

The First Version of the SCPI Script

*RST; TRAC:CLE "defbuffer1"; TRAC:POIN 10, "defbuffer1"; FUNC "TEMP", (@2:3); TEMP:UNIT CELS, (@2:3); TEMP:TRAN TC, (@2:3); TEMP:TC:TYPE K, (@2:3); TEMP:TC:RJUN:SIM 23, (@2:3); TEMP:NPLC 1, (@2:3); ROUT:SCAN:INT 60; ROUT:SCAN:COUN:SCAN 3; ROUT:SCAN:CRE (@2:3); ROUT:SCAN:EXP "/usb1/scan24hr", SCAN, ALL; ROUT:SCAN:REST ON; :DISP:SCR SWIPE_USER; INIT; *WAI; TRAC:DATA? 1, 6, "defbuffer1", READ;

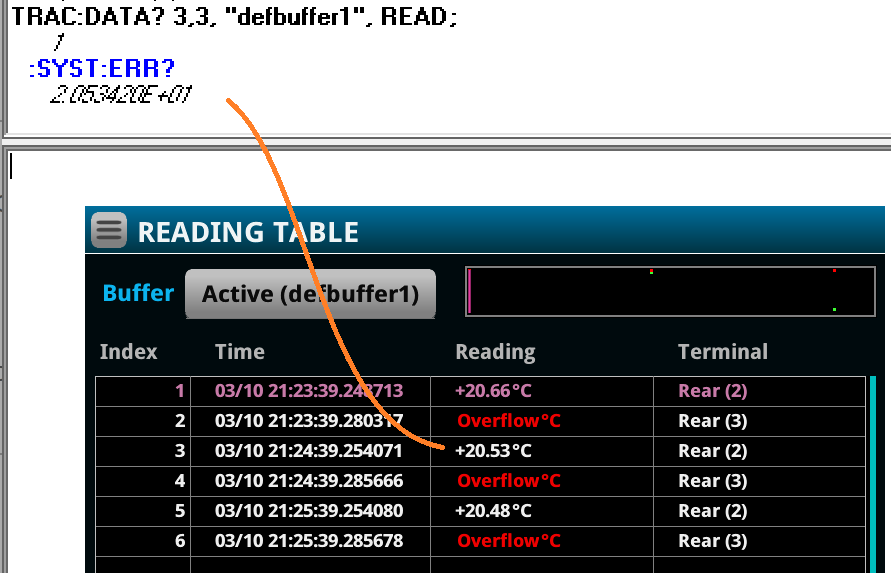

Here's a view of the results. Channel 2 and 3 sampled 3 times.

All samples are visible in the buffer display on the screen, and I read the 2nd sample of channel 2.

Channel 3 measures are in overflow because I didn't connect a thermocouple

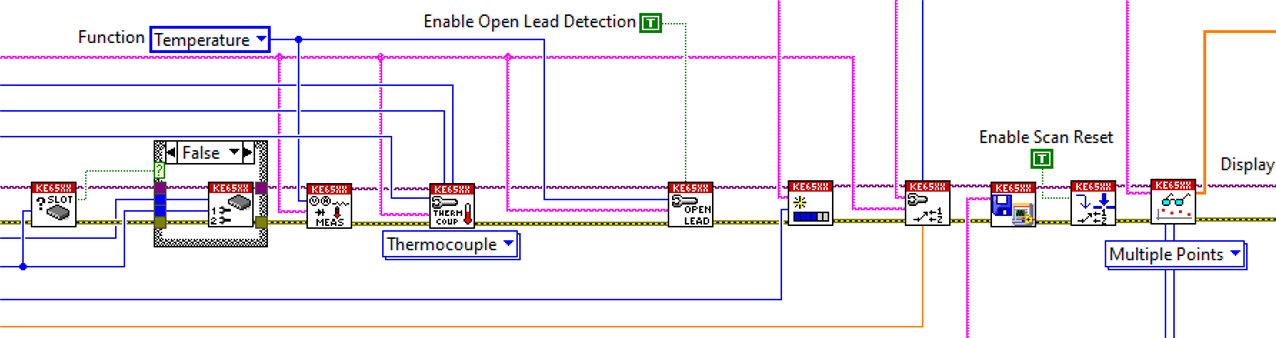

Below is how this will look like in LabVIEW, in a few blog posts.

scrap pad for my next post - ignore

if you don't ignore, you 'll find the instructions to define channel 1 as the cold junction sampler with a PT100 RTD. It is then set as the external reference for the other channels, instead of the simulation mode used in this blog.

18: Write Operation (TRAC:POIN\s500,\s"defbuffer1") Return Count: 26 bytes 2: Write Operation (FUNC\s"TEMP",\s(@1:3)) Return Count: 19 bytes 3: Write Operation (TEMP:UNIT\sCELS,\s(@1:2)) Return Count: 22 bytes 4: Write Operation (TEMP:TRAN\sRTD,\s(@1)) Return Count: 19 bytes 5: Write Operation (TEMP:TRAN\sTC,\s(@2)) Return Count: 18 bytes 6: Write Operation (TEMP:UNIT\sCELS,\s(@1:3)) Return Count: 22 bytes 7: Write Operation (TEMP:TRAN\sTC,\s(@2:3)) Return Count: 20 bytes 8: Write Operation (TEMP:TC:TYPE\sK,\s(@2:3)) Return Count: 22 bytes 9: Write Operation (TEMP:TC:RJUN:RSEL\sEXT,\s(@2:3)) Return Count: 29 bytes 10: Write Operation (EMP:NPLC\s1,\s(@2:3)) Return Count: 18 bytes 11: Write Operation (TEMP:NPLC\s1,\s(@2:3)) Return Count: 19 bytes 12: Write Operation (TEMP:NPLC\s1,\s(@2:3)) Return Count: 19 bytes 13: Write Operation (ROUT:SCAN:INT\s60) Return Count: 16 bytes 14: Write Operation (ROUT:SCAN:COUN:SCAN\s5) Return Count: 21 bytes 15: Write Operation (ROUT:SCAN:CRE\s(@1:3)) Return Count: 20 bytes 16: Write Operation (ROUT:SCAN:EXP\s"/usb1/scan24hr",\sSCAN, \sALL) Return Count: 41 bytes 17: Write Operation (INIT) Return Count: 4 bytes Return Count: 27 bytes 19: Write Operation (INIT) Return Count: 4 bytes 20: Write Operation (*WAI) Return Count: 4 bytes 21: Write Operation (TRAC:DATA?\s1,\stotalRdgs,\s"defbuffer1", \sREAD) Return Count: 43 bytes