|

I'm writing a flow to automate long-term temperature measurement.

|

DMM6500 Driver example

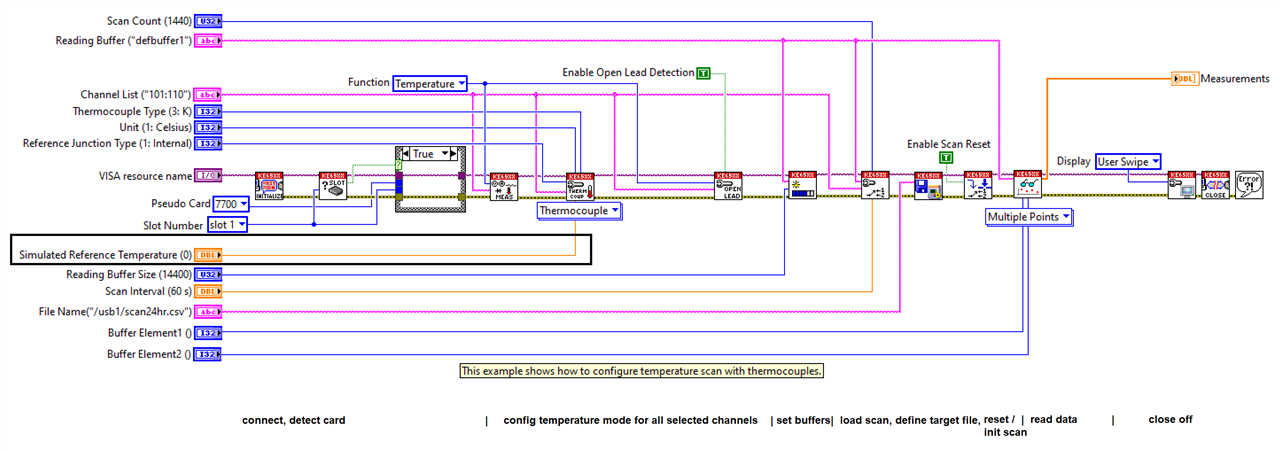

For most of the use cases that are explained in the user or reference manuals, there is also an example flow in the LabVIEW driver. Both Tektronix and Keithley have a (good) habit of doing that. It makes my job here easy. I can just use their Thermocouple example. The only change I have to make to the design, is to expose the field where I can set the simulated cold junction temperature. You can see that in the black rectangle below:

The flow is very similar to the script of the first post, except that it 'll do some checks first to see what hardware is available:

- the first 2 blocks and the case structure after that, connect to the meter and check what scanner card is installed.

- The next 3 blocks configure the channels for temperature, K-type thermocouple, and some other measurement attributes

- Then the scan gets loaded to the meter and primed.

- A destination for the file is defined

- In the Read block, everything starts running, until the complete scan process has executed

- Finally, the meter is set to a neutral screen, and the resources are closed.

What will I have to change when I use a PT100 for cold junction compensation?

The driver examples have a ready-to-use flow for using simulated compensation, and when using the dedicated 2001-TSCAN Thermocouple extension card. When you wire a PT100 in yourself, you (I in this case) will have to write some custom LabVIEW code.

That code will have to set the configuration of the PT100 on channel 1 first, before the thermocouple channels are configured. It 'l then have to take care that that channel 1 is part of the scanned channels. I don't think it 'll be a hard exercise, if I start from what's available as examples in the LabVIEW driver.