Let's imagine that you have to build a test jig for resistors. The task is to check if they are within tolerance. If the resistor is good, you have to put it in the "good" bin. The others ones need to be rejected.

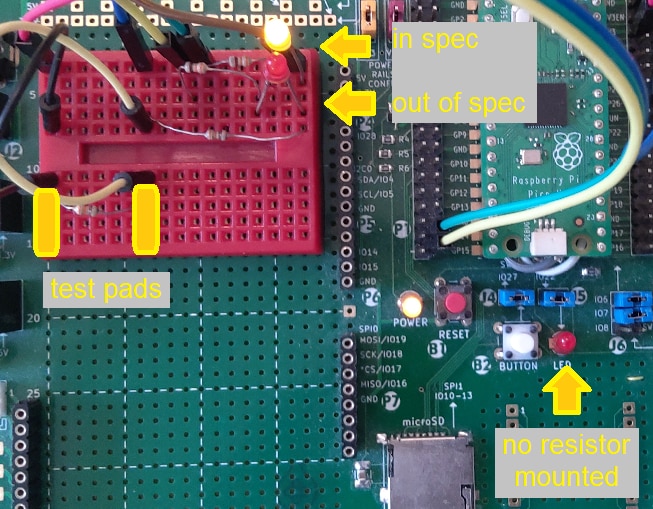

You can build a LabVIEW process with the Pico SCPI labTool (PST) to run this process. It has the necessary ADC inputs that can be used to test the resistor, and outputs that can control status LEDS*.

Requirements:

- check tolerance of a resistor. Is its value within range?

- indicate yes or no

- indicate if the test jig does not detect a resistor.

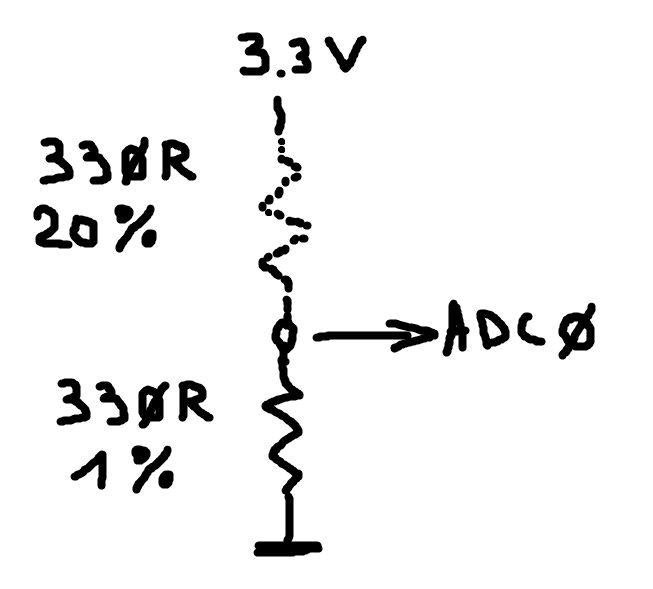

To test the resistor, you can use a divider, with a high precision known resistor and the "resistor under test" in series. You can sample the connection node with a LabVIEW driver ADC block.

Based on the sampled value, you can make the decision if it's within tolerance, and is allowed to be put in the "good" bin.

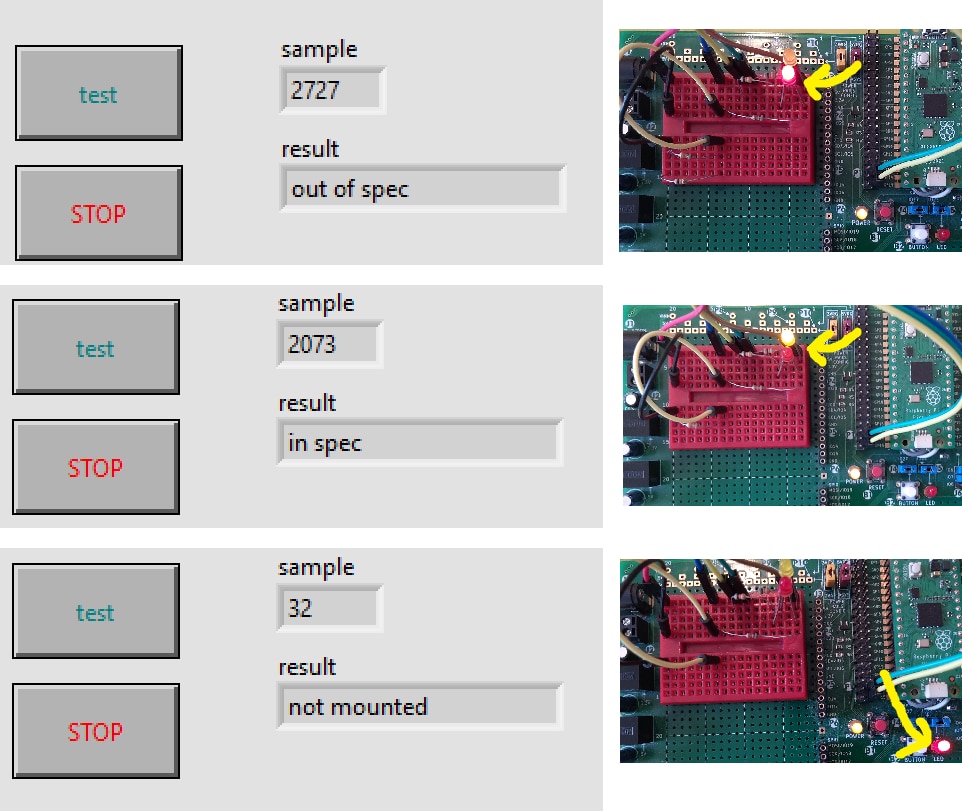

The GUI could look like this. The 3 cases are shown:

Connect LEDs with a series resistor to the PST digital outputs.

Connect the sample node to a PST analogue input.

Connect the high precision resistor to ground.

Mount your "resistor under test" between 3.3V and the other side of the high precision one.

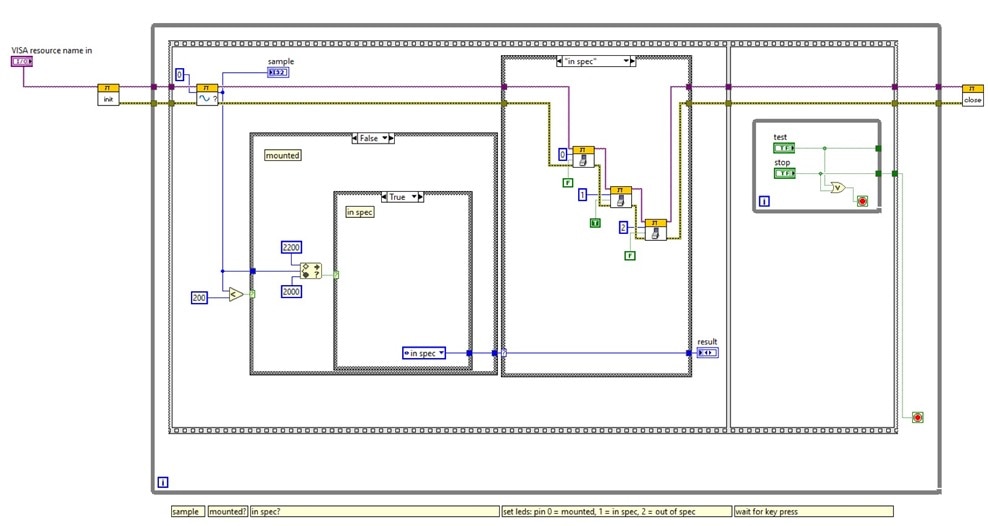

Flow suggestion:

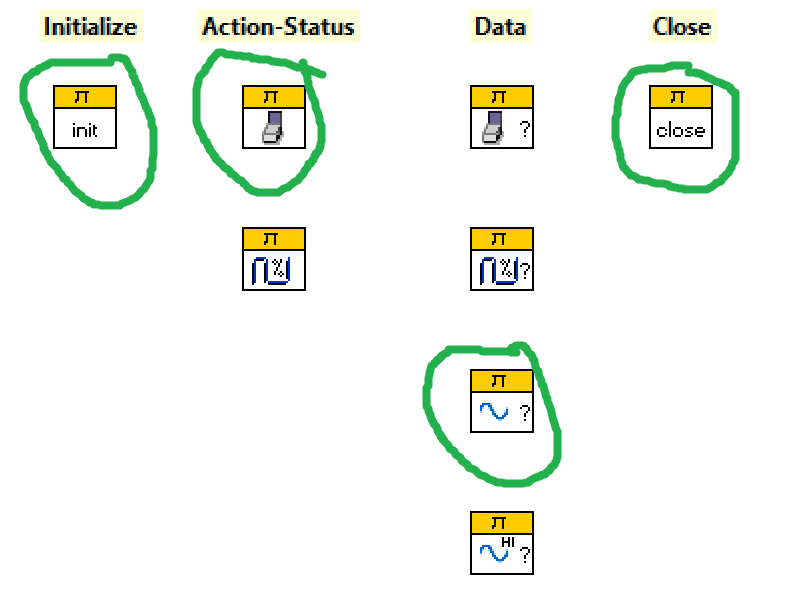

Blocks that look like this are PST LabVIEW driver components:![]()

Blocks used:

Everything else is out-of-box LabVIEW.

* in a industrial setup, this could be automated. Instead of LEDS, we'd use solenoids to push out-of-spec resistors in the rejected bin. Or sound a horn.

The on-screen button could be replaced by a footswitch or an optocoupler, that would spot if a new resitor is test ready (that is: when we finally implement "digital in" functionality)