Removing castellated PCBs, once soldered, can be a tricky task. It's not easy to get the solder on all castellations heated up at the same time.

I had to replace the XIAO RP2400 board on my Pi Pico Eurocard Development Board. Doing this with a high capacity iron, or with hot air isn't easy. By the time you get to pin 14, pin 1 has gone solid again.

You may get away with prying under the board while attacking each castellation, but chances are that you 'll tear off the pads from the motherboard.

One possible solution is to ply a thick copper wire in such a way that it surrounds the PCB and touches all castellations. Then, with a decent iron and a lot of flux, heat up that wire.

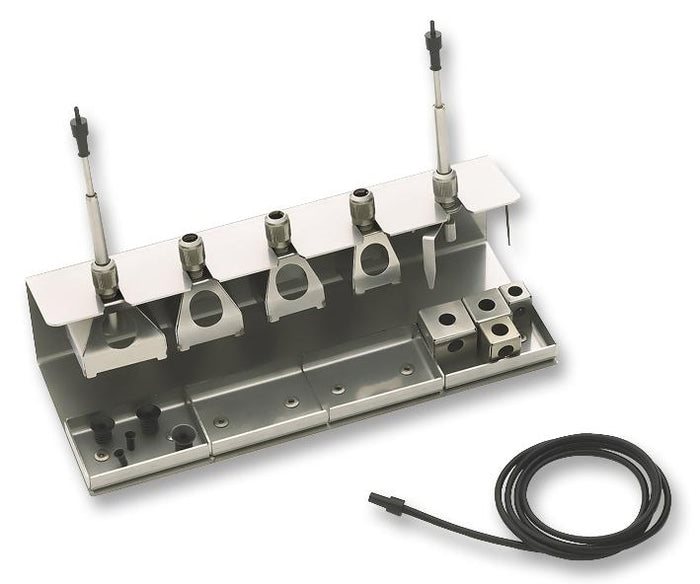

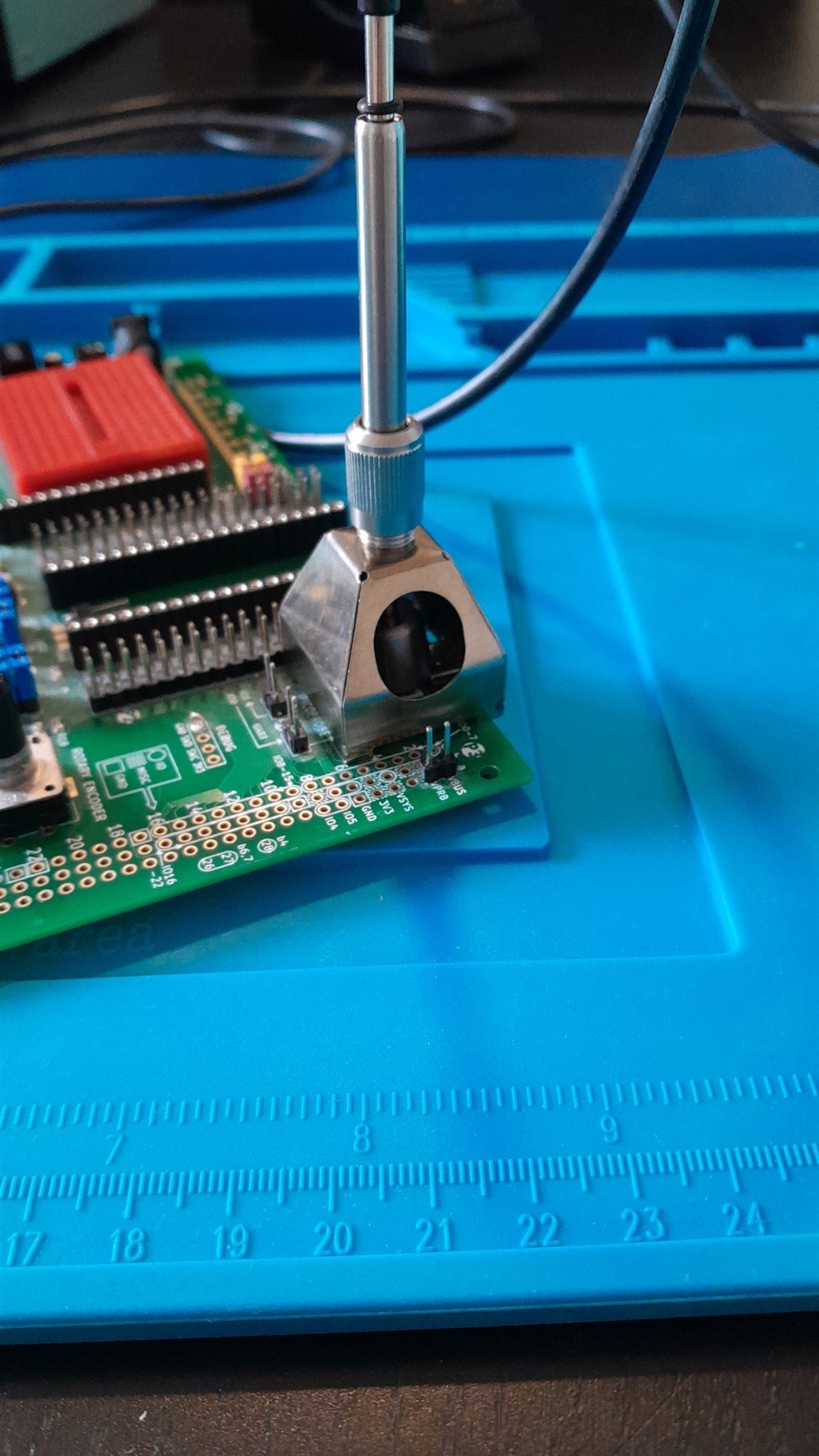

I decided to try removing the IC with a Weller WRK SMD reflow kit.

This kit has little ovens that you can put on top of something. And it has a vacuum-actioned suction cup that you can stick on top of the device that needs to be removed.

When you then put a hot air pencil in the little oven's opening, the inside gets hot very fast. No risk of burning the neighbour components. And very efficient heat usage.

When I tried this at 380° C, the castellated board lifted off in 20-30 seconds. Without any damage.

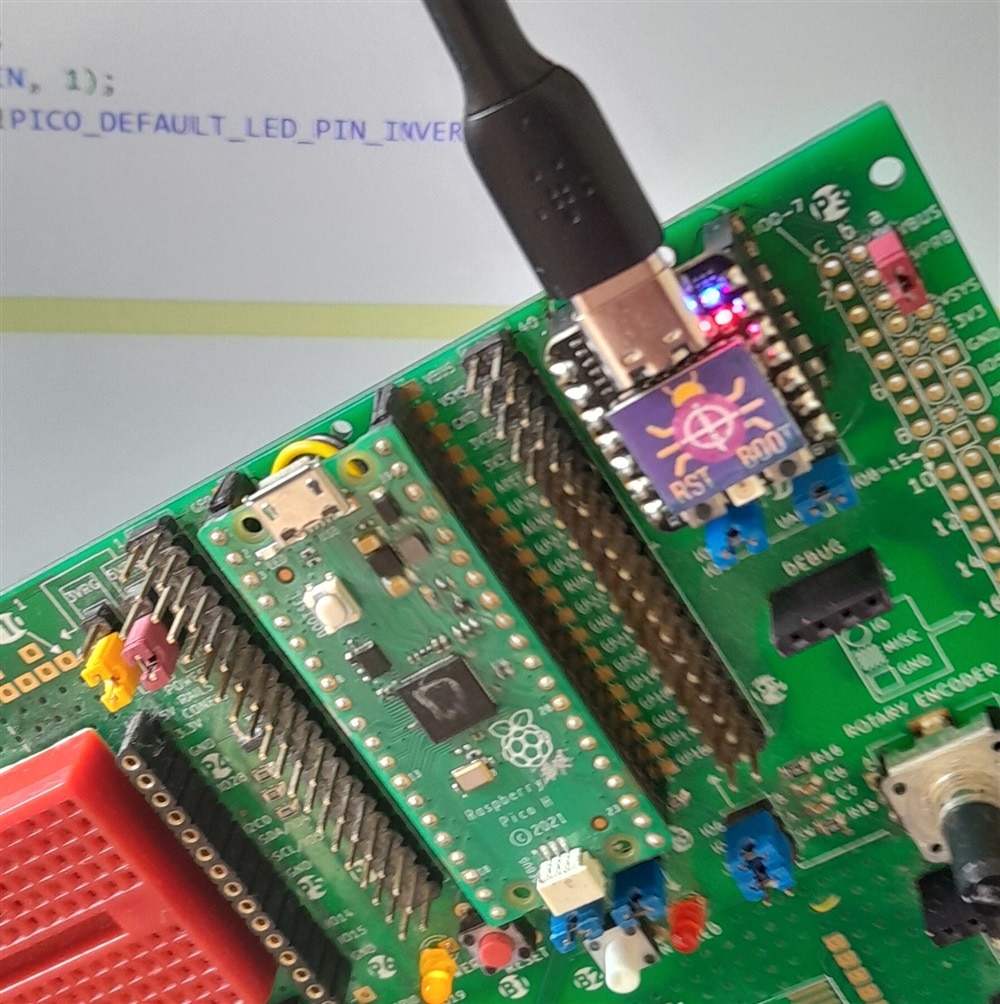

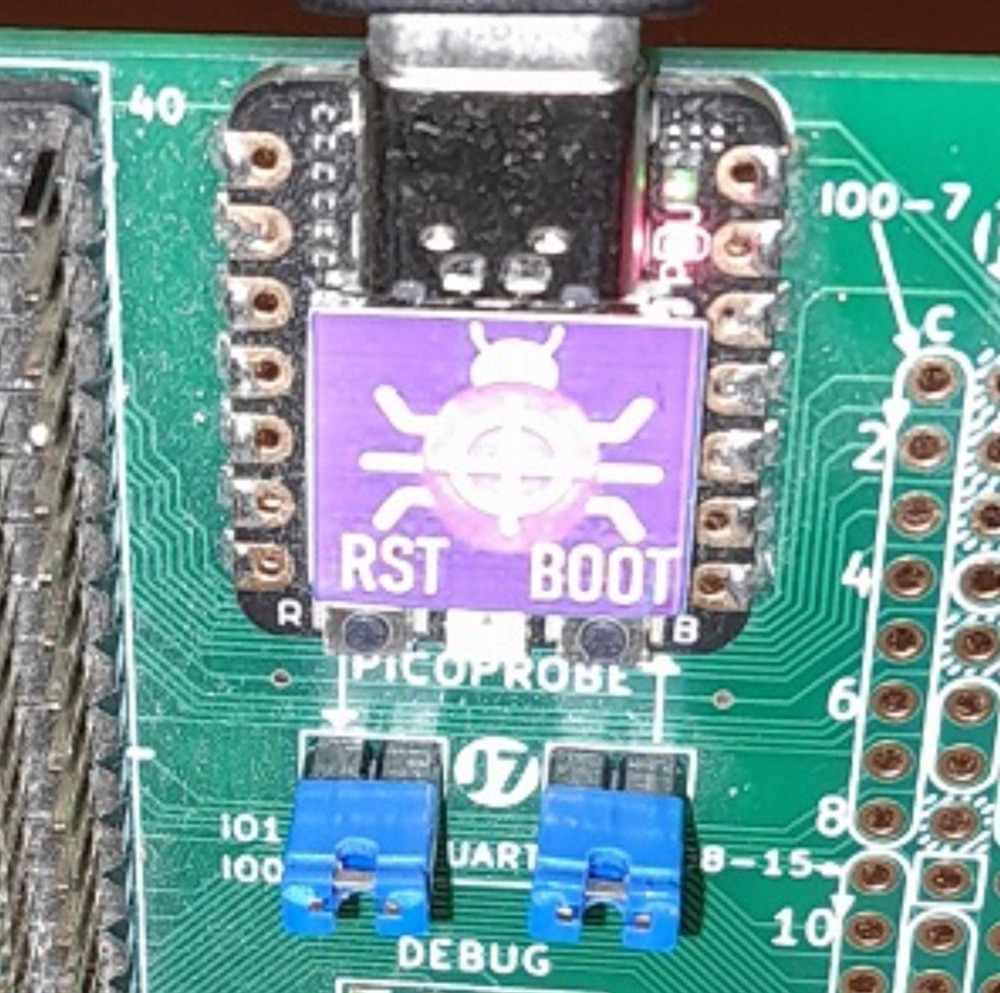

This is the motherboard after the action:

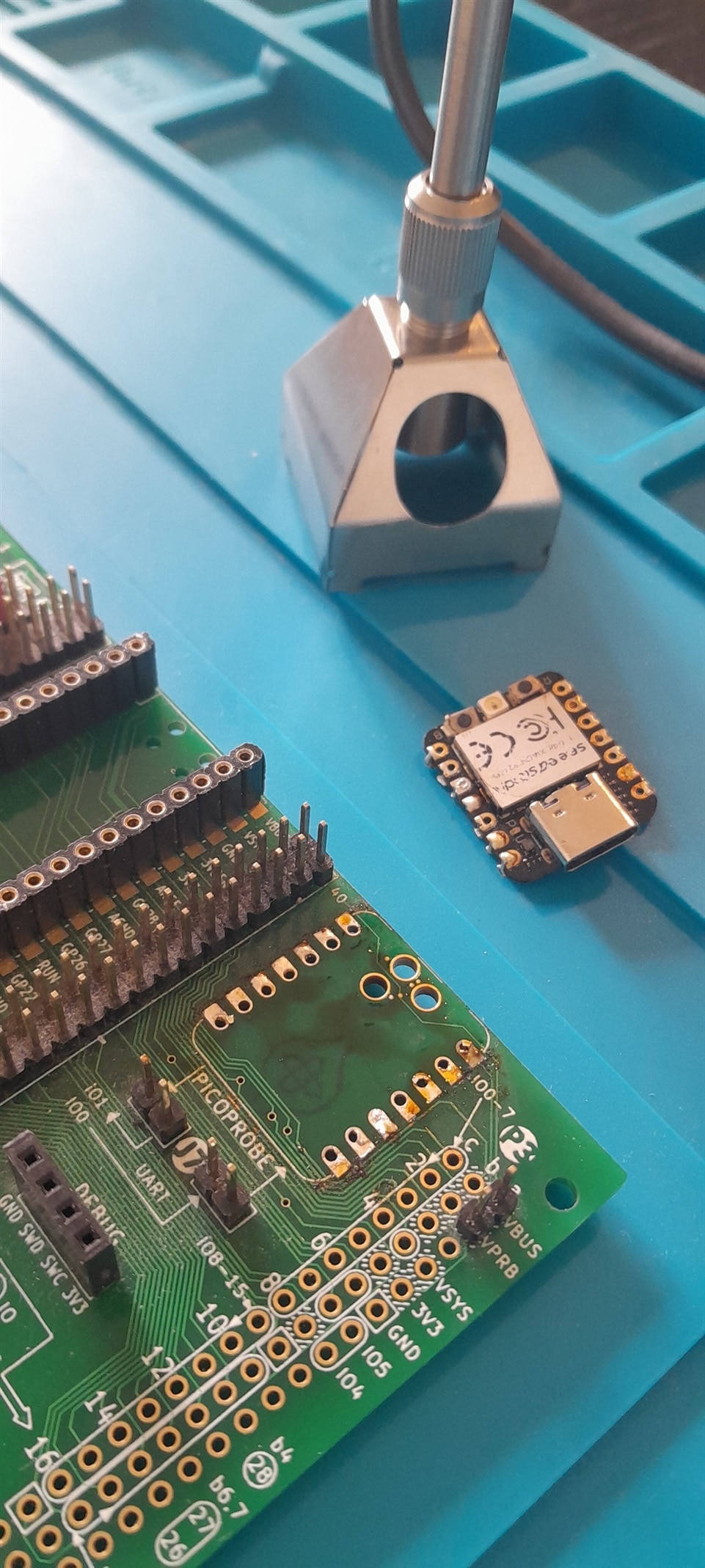

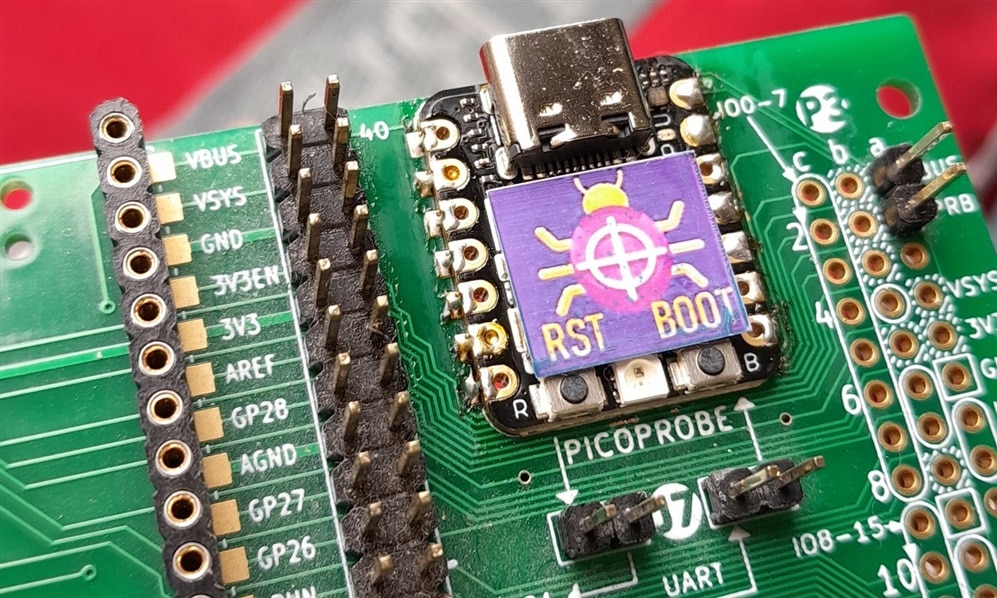

And the castellated board survived too:

There is a little alchemy and experience involved. In my case, the XIAO used lead-free solder, and the castellated board was placed with leaded.

That meant that the castellations melted faster than the components on the XIAO. And when the lift-off happened, the whole board came off.

It's not that easy in every case.

But you can prepare for this. In case the castellated board is placed with lead-free, You can first wick off most of that, and replace it with leaded solder (or even lower melting point specialised products). Then use the oven to remove everything.

Anyways, after this exercise, I cleaned up the motherboard and put on a new XIAO RP2040.

Thanks for reading.