APPLICATION NOTE

Low Force Crimp-Contacts

ANE001C BY ANDREAS AIGNER

1. Disconnection made easy

Although they are really designed for permanent connection, plug connectors with crimp contacts have to be disconnected every so often. To avoid this becoming a trial of strength for the maintenance technician who then damages the plug connector, Würth Elektronik eiSos developed an alternative with reduced insertion and pulling force.

Manufacturers of household electrical appliances have to take servicing into consideration, even in the development of their products. This means that components prone to wear and defects, such as the brewing unit of a coffee machine, have to be easily accessible. It is even more important to use components that are not damaged for the first time by the repair and are therefore sure to cause follow-on costs. Crimp plug connectors with more than 10 pins are examples of such components. Equipped with standard contacts, they can only be disconnected with great difficulty; with 24 pins they are almost impossible to disconnect. Given an installation situation which is complicated to access, smaller numbers of pins are enough to hamper disconnection of the wire-to-board connection. Because, in these place in particular, it is impossible to use tools, there is only one solution: to tug on the cable! And to mechanically damaged the plug connector in the process.

German Railways had just such problems with cramped conditions during maintenance work on the door controls of their carriages. The wish for a crimp plug connector with the same electrical properties as the one previously used, but easier to connect and disconnect and yet withstand the strong vibrations during travel, prompted Würth Elektronik eiSos to modify the standard crimp contact on the WR-MPC3 series.

2. New contact design, same performance

Standard and low-force crimp contacts are punched and bent parts with the same crimp zone. The secret of the low-force contact's reduced insertion and pulling forces lies in the modified contact geometry. Whereas the standard design has pronounced contact points, the low-force version is flexible as a result of its spring contacts. This flexibility required a change of material to achieve good relaxation behavior and consistent contact pressure on the one hand, and to counteract fatigue, on the other. Nevertheless, both have the same electrical properties: a current carrying capacity of max. 5 A (AWG 20-22) or 4 A (AWG 24), as well as a voltage of 250 V (rms) and performing a low contact resistance of 10mΩ.

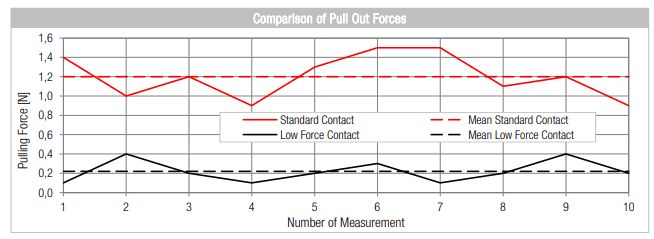

What is decisive, however, is the huge different in the insertion force, which for the standard contact is 8 N (max.) and for the low-force contact 4 N (max.), and the pulling force that has to be applied to the standard design of 3.7 N (min.) and to the low-force counterpart of 1.5 to 3 N. The new contact design achieves a reduction in the insertion force for a single contact of 50% and the pulling force is reduced by 20 to 50% (see graphic). The resulting improvement in handling the plug connector is particularly apparent from the example of a 24- pin plug connector: In the most favorable case of disconnection with standard design contacts, a force of 88.8 N (24 × 3.7 N) is necessary. A force of 72 N (24 × 3 N) has to be applied in the least favorable case with a low-force contact. So there is an effectively reduced application of force of 16.8 N.

Device manufacturers already profit from the low-force crimp contacts in product development. Because the connections often have to be made and disconnected again here, the high friction insertion and disconnection is considered troublesome. Nothing changes for the suppliers of pre-fitted cables: the low-force contacts can be crimped with the same machine as the standard design.

Figure 1: Comparison of Pulling Forces for Standard and Low Force Crimp-Contacts

The connection was disconnected ten times and the respective pulling forces required were measured. With a mean value of 0.22 N for the low-force crimp contact and an average pulling force of 1.2 N for the standard contact, there is a mean force reduction of 0.98 N.

|

|

| Figure 2: The standard crimp contact has a rigid contact sleeve | Figure 3: The sleeves on the low-force crimp contacts are equipped with springs that ease insertion and disconnection |

3. Bill of Materials

| MPN | Description | Farnell P/N |

| 66200113722 | WR-MPC3 Standard Crimp Contact | 1641838 |

| 66200313722 | WR-MPC3 Low Force Crimp Contact | 2472137 |

IMPORTANT NOTICE

Würth Elektronik eiSos GmbH & Co. KG and its subsidiaries and affiliates (WE) are not liable for application assistance of any kind. Customers may use WE’s assistance and product recommendations for their applications and design. The responsibility for the applicability and use of WE Products in a particular customer design is always solely within the authority of the customer. Due to this fact it is up to the customer to evaluate, where appropriate to investigate and decide whether the device with the specific product characteristics described in the product specification is valid and suitable for the respective customer application or not. The technical specifications are stated in the current data sheet of the products. Therefore the customers shall use the data sheets and are cautioned to verify that data sheets are current. The current data sheets can be downloaded at www.we-online.com. Customers shall strictly observe any product-specific notes, cautions and warnings. WE reserve the right to make corrections, modifications, enhancements, improvements, and other changes to its products and services.

WE DOES NOT WARRANT OR REPRESENT THAT ANY LICENSE, EITHER EXPRESS OR IMPLIED, IS GRANTED UNDER ANY PATENT RIGHT, COPYRIGHT, MASK WORK RIGHT, OR OTHER INTELLECTUAL PROPERTY RIGHT RELATING TO ANY COMBINATION, MACHINE, OR PROCESS IN WHICH WE PRODUCTS OR SERVICES ARE USED. INFORMATION PUBLISHED BY WE REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT CONSTITUTE A LICENSE FROM WE TO USE SUCH PRODUCTS OR SERVICES OR A WARRANTY OR ENDORSEMENT THEREOF.

WE products are not authorized for use in safety-critical applications, or where a failure of the product is reasonably expected to cause severe personal injury or death. Moreover WE products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc. Customers shall inform WE about the intent of such usage before design-in stage. In certain customer applications requiring a very high level of safety and in which the malfunction or failure of an electronic component could endanger human life or health customers must ensure that they have all necessary expertise in the safety and regulatory ramifications of their applications, and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any use of WE products in such safety-critical applications, notwithstanding any applications-related information or support that may be provided by WE. CUSTOMERS SHALL INDEMNIFY WE AGAINST ANY DAMAGES ARISING OUT OF THE USE OF WE PRODUCTS IN SUCH SAFETY-CRITICAL APPLICATIONS.

DIRECT LINKS

ANE001: Disconnection made easy

USEFUL LINKS:

Application Notes : https://we-online.com/en/support/knowledge/application-notes

Services: https://we-online.com/en/products/components/service

Contact : https://we-online.com/en/support/contact

CONTACT INFORMATION

Würth Elektronik eiSos GmbH & Co. KG

Max-Eyth-Str. 1, 74638 Waldenburg, Germany

Tel.: +49 (0) 7942 / 945 – 0

Email: appnotes@we-online.de