Application Note

Hot plugging of PoE Modular Jacks

ANE008 BY ALEXANDRE CHAILLET / CONSTANTIN LEMARQUIS

1 Introduction

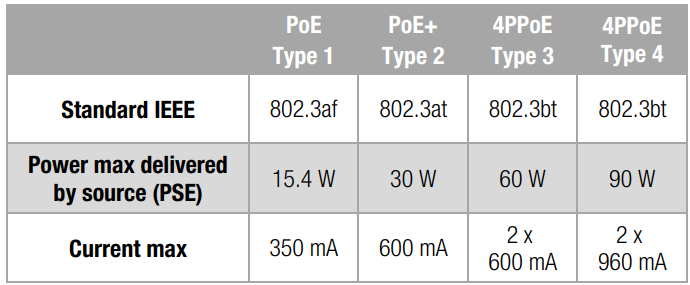

Modular jacks (MJ) connectors and cables are broadly used to bring Ethernet signal up to 10 Gb/s depending on the category of the product. It is also possible to deliver power through it. This is called PoE (Power over Ethernet), defined by IEEE 802.3 standard, which is divided in four different types, providing different Power delivery as shown in Table 1.

Table 1: Summary of the different PoE power classes

Type 1 and 2 PoE specifications are applicable to Würth Elektronik modular jacks. In this Application Note we will study if recommendations can be extended up to Type 4. Moreover most WE MJ connectors are rated up to 1.5 A. That is why they will be tested at this current. However, like all of the other types of input/output connectors, MJ connectors should not be plugged and unplugged (hot swapped) under load. Disconnectors products (breakers, switch, etc.) have special disconnection areas to be able to break the electric arc without damaging the contacts. This Application Note will show the capabilities of modular jacks in case they are accidently used as a disconnector product in a PoE application.

2 Hot swap tests

2.1 Electrical sparks

A disconnection under load (voltage and current) must cut the current between mating contacts. The power will ionize the air between the contacts which will let current go through it until the separation distance is too large. This spark or electric arc can damage both sides of the connector. At low power, sparks can degrade the plating and thus drastically decrease contact quality over time.

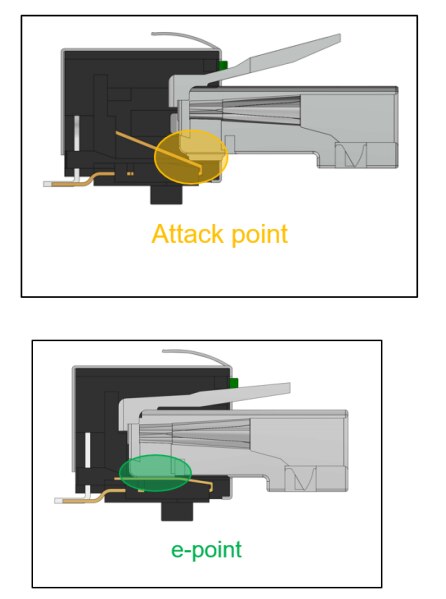

2.2 Modular jack connection

All Würth Elektronik modular jacks are gold plated with a nickel underlay, ensuring a very stable and optimized electrical contact during its mating life cycle specifications. We saw that sparks are likely to create plating damages. It has been found that sparking can cause damage to the coating. When a connector is inserted into the jack, the electrical contacts first mate at the front end of the jack contact spring (attack point). Then the contact point moves towards the rear end of the contact spring (E-Point). The mechanical and electrical contact points are therefore physically separated from each other. Even if the coating on the first contact point is being damaged, the electrical contact remains unharmed.

Figure 1: Modular jack contact

2.3 Test plan and results

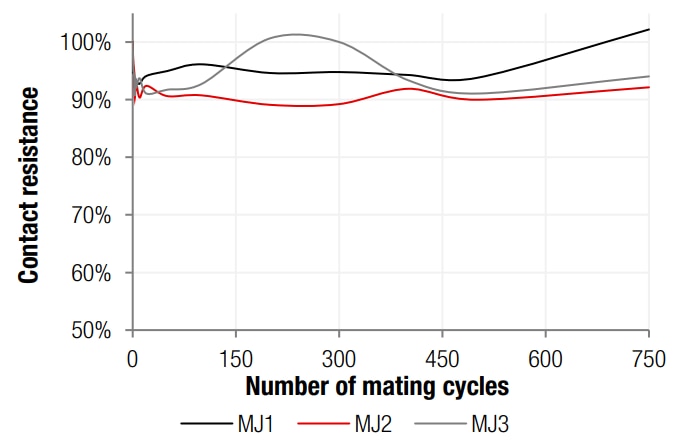

Contact resistance change is monitored to highlight any contact pin damage. The rated 750 mating cycles are performed as per WE modular jack specifications. The initial measurement is done without current for a reference. Then the worst case simulation is performed at 1,5 A. This covers PoE capabilities up to Type 4 (960 mA). The test is performed on three different modular jack designs and all products are new out of the stock.

Figure 2: Contact resistance change vs. mating cycle under load at 1.5 A

Values are presented in percent for a clearer comparison of the change. The initial measurement at zero current is 100 % for each modular jack.

First observations:

- All the values decrease after the first measurement.

- Contact resistance is very stable for the three samples

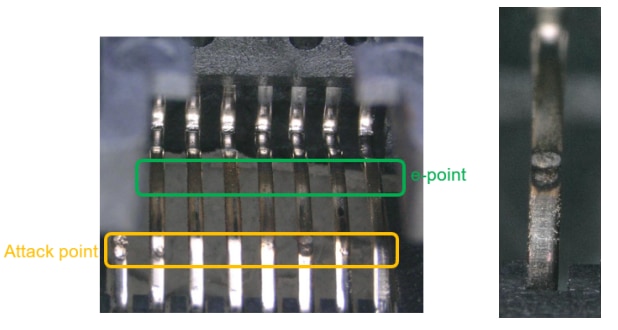

- Electrical contact area does not show any traces of degradation after 750 mating cycles under load.

- Visible degradation at the contact point area does not impact the usebilty of the MJ’s

Figure 3: Modular jack pins after 750 mating cycles at 1.5 A

Conclusions:

- Contaminants are remove by the wiping action of the contacts during insertion. Modular jacks from Würth Elektronik are self-cleaning

- Hot swap has no impact on the quality of the electrical contact at the e-point with up to 1.5 A and 750 mating cycles

- Samples were from CAT 3, CAT 5e, and CAT 6 products. The jack’s category is independent of hot swap capability

3 Summary

Electrical switches products are designed to open and close circuit under load. Modular jacks are not switches so they are not meant to be plugged and unplugged under load. However, Würth Elektronik modular jacks, thanks to their design are able to withstand accidental mating cycles under load whenever used within the current specifications.

IMPORTANT NOTICE

The Application Note is based on our knowledge and experience of typical requirements concerning these areas. It serves as general guidance and should not be construed as a commitment for the suitability for customer applications by Würth Elektronik eiSos GmbH & Co. KG. The information in the Application Note is subject to change without notice. This document and parts thereof must not be reproduced or copied without written permission, and contents thereof must not be imparted to a third party nor be used for any unauthorized purpose. Würth Elektronik eiSos GmbH & Co. KG and its subsidiaries and affiliates (WE) are not liable for application assistance of any kind. Customers may use WE’s assistance and product recommendations for their applications and design. The responsibility for the applicability and use of WE Products in a particular customer design is always solely within the authority of the customer. Due to this fact it is up to the customer to evaluate and investigate, where appropriate, and decide whether the device with the specific product characteristics described in the product specification is valid and suitable for the respective customer application or not. The technical specifications are stated in the current data sheet of the products. Therefore the customers shall use the data sheets and are cautioned to verify that data sheets are current. The current data sheets can be downloaded at www.we-online.com. Customers shall strictly observe any product-specific notes, cautions and warnings. WE reserves the right to make corrections, modifications, enhancements, improvements, and other changes to its products and services. WE DOES NOT WARRANT OR REPRESENT THAT ANY LICENSE, EITHER EXPRESS OR IMPLIED, IS GRANTED UNDER ANY PATENT RIGHT, COPYRIGHT, MASK WORK RIGHT, OR OTHER INTELLECTUAL PROPERTY RIGHT RELATING TO ANY COMBINATION, MACHINE, OR PROCESS IN WHICH WE PRODUCTS OR SERVICES ARE USED. INFORMATION PUBLISHED BY WE REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT CONSTITUTE A LICENSE FROM WE TO USE SUCH PRODUCTS OR SERVICES OR A WARRANTY OR ENDORSEMENT THEREOF. WE products are not authorized for use in safety-critical applications, or where a failure of the product is reasonably expected to cause severe personal injury or death. Moreover, WE products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc. Customers shall inform WE about the intent of such usage before design-in stage. In certain customer applications requiring a very high level of safety and in which the malfunction or failure of an electronic component could endanger human life or health, customers must ensure that they have all necessary expertise in the safety and regulatory ramifications of their applications. Customers acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any use of WE products in such safetycritical applications, notwithstanding any applications-related information or support that may be provided by WE. CUSTOMERS SHALL INDEMNIFY WE AGAINST ANY DAMAGES ARISING OUT OF THE USE OF WE PRODUCTS IN SUCH SAFETY-CRITICAL APPLICATIONS.

DIRECT LINK

ANE008: Hot plugging of PoE Modular Jacks

USEFUL LINKS:

Application Notes : https://we-online.com/en/support/knowledge/application-notes

Services: https://we-online.com/en/products/components/service

Contact : https://we-online.com/en/support/contact

CONTACT INFORMATION

Würth Elektronik eiSos GmbH & Co. KG

Max-Eyth-Str. 1, 74638 Waldenburg, Germany

Tel.: +49 (0) 7942 / 945 – 0

Email: appnotes@we-online.de