Application Note

Auxiliary supply requirements for SiC/GaN gate driver systems

ANP082 BY Andreas Nadler, Eleazar Falco, Emil Nierges

01. INTRODUCTION

Wide bandgap power semiconductor devices like Silicon Carbide (SiC) MOSFETs are enjoying growing popularity in many modern power electronic applications like E-mobility and renewable energy. Their extremely fast switching speed capability helps to increase efficiency and reduce the overall size and cost of the system. However, fast switching together with high operating voltages and increasing switching frequencies presents important challenges to the gate driver system. Rugged galvanic isolation, compliance with safety standards, control signal noise immunity and EMI performance are just some of the most important aspects to consider. An optimal design of the isolated auxiliary supply providing the voltage and current levels to drive the SiC/GaN device is critical to help the full gate driver system meet the many requirements set by state-of-the-art applications.

02. OVERVIEW AND REQUIREMENTS FOR GATE CONTROL OF HV SIC / GAN FET DEVICES

Figure 1: Overview of a HV half-bridge control of the High-side & Low-side SiC-MOSFET.

In applications using SiC/GaN high-voltage semiconductor devices under hard-switching operation, galvanic isolation is a common requirement for safety and functional reasons, and depending on the application, a basic or a reinforced insulation will be required. The operating voltage, insulation material, pollution degree and the applicable regulatory standards set the minimum creepage and clearance distances as well as the dielectric isolation voltage requirement affecting the components placed across the isolation barrier. The high-speed isolated gate driver IC (e.g. TI UCC21520) and the transformer in the isolated auxiliary power supply (DC/DC Block in figure 1) both ‘bridge’ this isolation barrier, thus having to meet stringent safety and functional requirements.

The latest SiC MOSFETs require gate-source voltages between +15 V and +20 V to fully turn on and between 0 V and -5 V to reliably turn off. For the gate of a gallium nitride FET (GaN 650 V) usually only +5 V and 0 V are required. In some cases, a small negative voltage is also used to turn off the GaN FET. Please note that these values vary depending on manufacturer. In figure 1, a half-bridge configuration is shown, and several of these stages are typically required in an inverter circuit to drive AC-motors in the kW range. Each SiC/GaN FET would require an independent gate driver stage with its own isolated auxiliary supply. This not only enables individual control of each SiC/GaN device, but also helps to keep the gate current loop small and local to the device, minimizing the adverse effects of parasitic loop inductance and ground bounce caused by the very high ΔI/Δt generated during the switching transition (figure 2 and figure 3).

Figure 2: High ΔI/Δt current paths on turn-ON of SiC/GaN FET.

Figure 3: High ΔI/Δt current paths on turn-OFF of SiC/GaN FET.

If ignored, this may lead to uncontrolled turn-on/off of the MOSFET and thermal issues. Some SiC MOSFETs are designed with an additional low impedance Kelvin source connection for a gate current return path (figure 4).

Figure 4: Kelvin connections and critical parasitic inductances in a half-bridge configuration.

This connection does not carry the high switching current and therefore has a lower interference potential due to lower parasitic inductance than the source connection, which significantly improves gate driving. (e.g. Infineon

IMZ120R045M1 1200 V / 52 A). Regarding the auxiliary supply, its output capacitors (with minimal ESL and ESR) should be placed very close to the gate driver IC and SiC/GaN device to minimize the gate current loop and with it its parasitic inductance in order to reduce the associated parasitic effects (i.e. ringing).

03. REQUIREMENTS OF THE ISOLATED GATE DRIVER POWER SUPPLY FOR SICMOSFETS

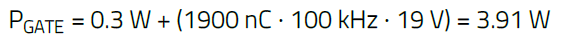

There is currently a large selection of compact, isolated 1 – 2 W DC/DC converters available on the market. For a SiCMOSFET like the Infineon IMZ120R045M1 1200 V / 52 A, up to 1 W power requirement per device can be estimated (see example calculation (1)). However, an application with over 5 kW load power would require the use of either a SiC-MOSFET module (e.g. ROHM BSM600D12P3G001 1200 V / 600 A) or alternatively several discrete SiC-MOSFETs in parallel (current sharing). In a module solution, several semiconductor dies are paralleled to form the final SiC-MOSFET. This technique reduces the effective RDS(ON) but results in a higher "Total Gate

Charge", requiring more driver power from the auxiliary supply (example calculation (2)). Above 2 W of power, there is only a very limited selection of off-the-shelf isolated DC-DC converter modules, which despite their convenience, they often come at a premium cost while being larger than discrete solutions and with efficiencies lining under 80%.

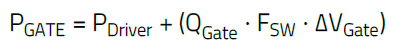

PGate Total power required to drive the SiC device gate

PDriver Power loss in the gate driver section (approx. 0.3 W)

QGate Total Gate Charge value (from datasheet)

FSW Maximum switching frequency

ΔVGate Maximum voltage swing at the gate from –Vee to +Vdd (e.g. -4 V to +15 V = 19 V)

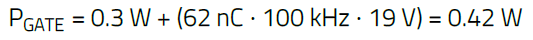

Example calculation (1) with Infineon IMZ120R045M1 1200 V/ 52 A:

Example calculation (2) with ROHM BSM600D12P3G0011200 V / 600 A:

The currently available SiC MOSFET modules can feature a total gate charge from as little as a few hundred nC up to 3000 nC. The higher their blocking voltage and rated power, the higher their gate capacitance. With an increase in the switching frequency or load power(requiring more SiC devices connected in parallel with the corresponding increase in total gate charge) 6 - 10 W of driver system power can be expected for the most demanding current and future applications.

Efficiency, size and especially the parasitic coupling capacitance are all important parameters in highperformance SiC-based systems. With increasing switching speed and the resulting very steep switching slopes, more harmonic energy is capacitively coupled between the converter output stage/gate driver (high-voltage side) and thelow-voltage control side.

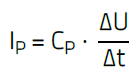

The parasitic capacitance (CP) between primary and secondary sides in the gate driver auxiliary supply is mainly set by the interwinding capacitance of the DC/DC power transformer device. With latest SiC-MOSFETs switching at ΔU/Δt slew rates of 100 kV/us, 10 pF parasitic capacitance would cause a peak displacement current of 1 A across the isolation barrier.

A high displacement current degrades the insulation barrier in the long run, interferes with the control signals and leads to common mode currents, which are a typical cause of EMI problems.

IP electrical displacement current

CP parasitic coupling capacitance

It is generally recommended to keep Cp in the auxiliary supply below 10 pF.

However, consider that the maximum capacitance tolerated in any application depends on the switching speed and CMTI (Common-mode Transient Immunity) capability of the gate driver IC used.

Würth Elektronik has addressed these challenges and presents optimized solutions with its new reference designs for SiC and IGBT gate drivers. These designs are based on the new WE-AGDT transformers, which feature a very low winding capacitance of up to 6.8 pF. They offer various wellregulated bipolar and unipolar gate drive voltages with an output power of up to 6 W in an extremely compact form factor (27 x 14 x 14 mm (L x W x H)).

04. WÜRTH ELEKTRONIK SOLUTIONS UP TO 6W (10W)

The RD001 reference design with bipolar output provides the following specification:

- Input voltage range: 9 - 18 V

- Output voltage variant 1: +15 V / -4 V

- Output voltage variant 2: +19 V / -4 V

- Output voltage variant 3: +20 V / -5 V

- Peak efficiency of up to 86% (83% @ 6 W)

Figure 5: Würth Elektronik reference design for a compact, isolated DC/DC converter for HV SiC/GaN/IGBT Gate Driver

Figure 6: Voltage of Positive and Negative rails versus load power (@ VIN (nominal) = 12 V)

The RD002 reference design with bipolar output provides the following specification:

- Input voltage range: 9 - 18 V

- Output voltage variant 1: 15 V

- Output voltage variant 2: 18 V

- Output voltage variant 3: 20 V

- Peak efficiency of up to 88% (86% @ 6 W)

In addition to the controller IC (ADI Power by Linear), the key components in these reference designs are the new WEAGDT transformer series. A compact EP7 customized package was used and optimized to meet the following requirements:

- Wide Input Voltage Range: 9 - 36 V

- Very low interwinding capacitance typ. 6.8 pF

- Very low leakage inductance

- SMD Pick & Place ready

- Safety Standard IEC-62368-1, IEC-61558-2-16

- Basic Insulation for VBUS: 800 VDC

- Dielectric Isolation min. 4 kV AC

- Temperature Class B 130 °C

- AEC-Q200 Qualification

Each transformer from the WE-AGDT series is optimized for different specifications and its own reference design. Note that these power transformers can be used not only for gate drive systems of SiC MOSFETs, but also for IGBTs and high voltage silicon based power MOSFETs. For currently available HV GaN FETs, an additional output stage (step-down) may be required due to the lower maximum gate voltage that GaN devices can tolerate.

The reference design RD001 and RD002 with the corresponding PCB layout files (Altium Designer 21) as well as the PCB manufacturing files can be downloaded from the Würth Elektronik website.

Please note that the output power of these reference designs can be scaled up to 10 W by using an EP10 package and replacing some components.

For specific requirements, please contact Würth Elektronik engineers.

05. SUMMARY

With the new WE-AGDT transformer series, Würth Elektronik addresses the current and future challenges in the field of power electronics and gives engineers the possibility to easily implement a discrete solution of a very compact and efficient gate driver supply with up to 6 W output power, which meets the low interwinding capacitance requirements demanded by many modern applications with fast switching SiC/GaN as well as IGBT devices.

IMPORTANT NOTE

The Application Note is based on our knowledge and experience of typical requirements concerning these areas. It serves as general guidance and should not be construed as a commitment for the suitability for customer applications by Würth Elektronik eiSos GmbH & Co. KG. The information in the Application Note is subject to change without notice. This document and parts thereof must not be reproduced or copied without written permission, and contents thereof must not be imparted to a third party nor be used for any unauthorized purpose.

Würth Elektronik eiSos GmbH & Co. KG and its subsidiaries and affiliates (WE) are not liable for application assistance of any kind. Customers may use WE’s assistance and product recommendations for their applications and design. The responsibility for the applicability and use of WE Products in a particular customer design is always solely within the authority of the customer. Due to this fact it is up to the customer to evaluate and investigate, where appropriate, and decide whether the device with the specific product characteristics described in the product specification is valid and suitable for the respective customer application or not.

The technical specifications are stated in the current data sheet of the products. Therefore the customers shall use the data sheets and are cautioned to verify that data sheets are current. The current data sheets can be downloaded at www.we-online.com. Customers shall strictly observe any product-specific notes, cautions and warnings. WE reserves the right to make corrections, modifications, enhancements, improvements, and other changes to its products and services.

WE DOES NOT WARRANT OR REPRESENT THAT ANY LICENSE, EITHER EXPRESS OR IMPLIED, IS GRANTED UNDER ANY PATENT RIGHT, COPYRIGHT, MASK WORK RIGHT, OR OTHER INTELLECTUAL PROPERTY RIGHT RELATING TO ANY COMBINATION, MACHINE, OR PROCESS IN WHICH WE PRODUCTS OR SERVICES ARE USED. INFORMATION PUBLISHED BY WE REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT CONSTITUTE A LICENSE FROM WE TO USE SUCH PRODUCTS OR SERVICES OR A WARRANTY OR ENDORSEMENT THEREOF.

WE products are not authorized for use in safety-critical applications, or where a failure of the product is reasonably expected to cause severe personal injury or death. Moreover, WE products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc. Customers shall inform WE about the intent of such usage before design-in stage. In certain customer applications requiring a very high level of safety and in which the malfunction or failure of an electronic component could endanger human life or health, customers must ensure that they have all necessary expertise in the safety and regulatory ramifications of their applications. Customers acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any use of WE products in such safety-critical applications, notwithstanding any applications-related information or support that may be provided by WE.

CUSTOMERS SHALL INDEMNIFY WE AGAINST ANY DAMAGES ARISING OUT OF THE USE OF WE PRODUCTS IN SUCH SAFETY-CRITICAL APPLICATIONS.

DIRECT LINKS

ANP082: Auxiliary supply requirements for SiC/GaN gate driver systems

USEFUL LINKS:

Application Notes : https://we-online.com/en/support/knowledge/application-notes

Services: https://we-online.com/en/products/components/service

Contact : https://we-online.com/en/support/contact

CONTACT INFORMATION

Würth Elektronik eiSos GmbH & Co. KG

Max-Eyth-Str. 1, 74638 Waldenburg, Germany

Tel.: +49 (0) 7942 / 945 – 0

Email: appnotes@we-online.de