Electronics for good – mushroom farming in Cambodia using WE technology

Author: Sofie-Marie Wacker

Mushroom cultivation has had a long history in Southeast Asian countries, providing essential nutrients for people. However, the problem of traditional mushroom cultivation is high manual work for the Cambodian farmers. With current simple methods of temperature and humidity regulations, the yield depends on the seasonality of rainy, dry and hot season. Most potential to increase their income is to ensure good harvest in low yield high price season, meaning hot season.

The purpose is to minimize said problems to enable a simpler life to farmers. In the future, farmers should be able to buy a then mature system for their own use and manage the growth of their farm. In collaboration with a non-governmental organization, the farmers can purchase the system and invest in their future. This phase of the project is mainly focused on designing and iterating. Since Cambodia has a lower standard of living, the goal is to keep the cost for the end product as low as possible. iDE Innovation Lab and Würth Elektronik eiSos collaborated for a few years to support the NGO with technical questions and their experience in electronic devices. In this project we also had support from Institute of Technology of Cambodia who can provide assistance on site.

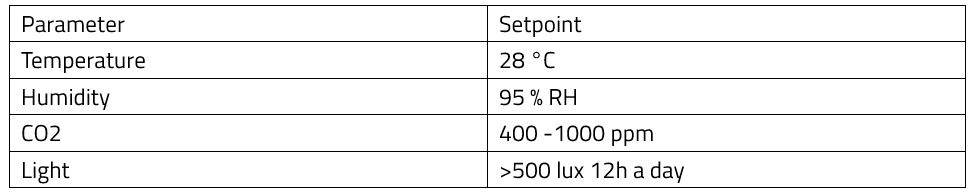

As usual, the first part of a project is research (well it should be). In this case, the research was different because we went directly to farmers to interview them about the work and process. We also proceeded to take measurements in their mushroom houses. A control system can only work if the setpoints fit to the application. Results are shown in the following table.

Table 1: Environmental conditions for growing oyster mushroom

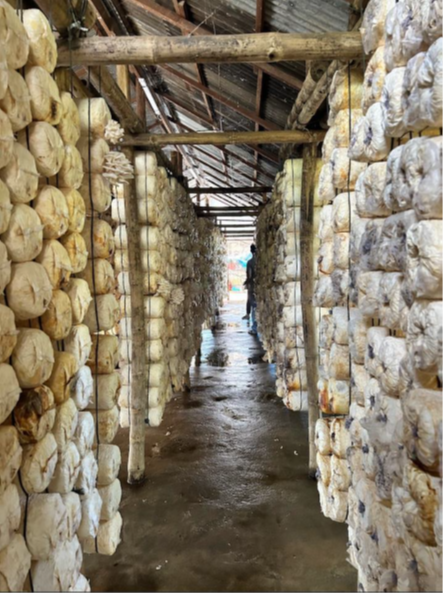

Figure 1: Inside of a mushroom growing environment

Figure 2: Project team at the sight

As you may expect, especially high humidity close to 100% RH can cause problems with electronic devices. After some time, the first prototype stopped working. The humidity and temperature sensor showed constant zero values. We proposed a solution to replace the existing humidity sensor with a WSEN-HIDS humidity and temperature sensor. An integrated heater makes the sensor a good fit for a high humidity environment. If condensation forms in the housing, the recovery works faster. As a negative point, the measured data during heating is invalid. But as mushroom farming is not that time critical, this is acceptable. The sensors are all connected by I2C. Disadvantage is a short maximum distance to the controller.

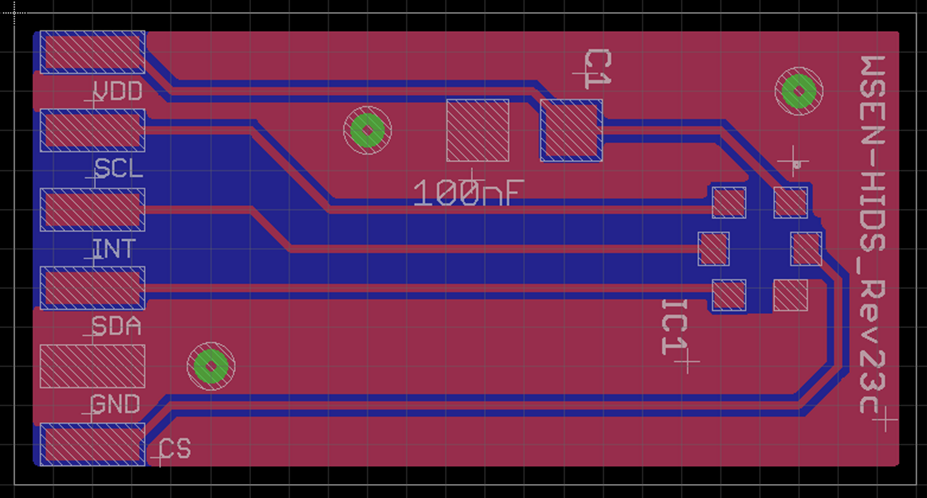

To mount the sensor, we have designed a small PCB with a 100 nF decoupling capacitor between supply voltage and ground. The final design is shown in the picture below. Dimensions are 7.62 x 14.61 mm (300 x 575 mil). The capacitor is a WCAP-CSGP multilayer ceramic chip capacitor with the size 0603. To keep costs low, this PCB only has two layers.

Figure 3: PCB design for sensor board

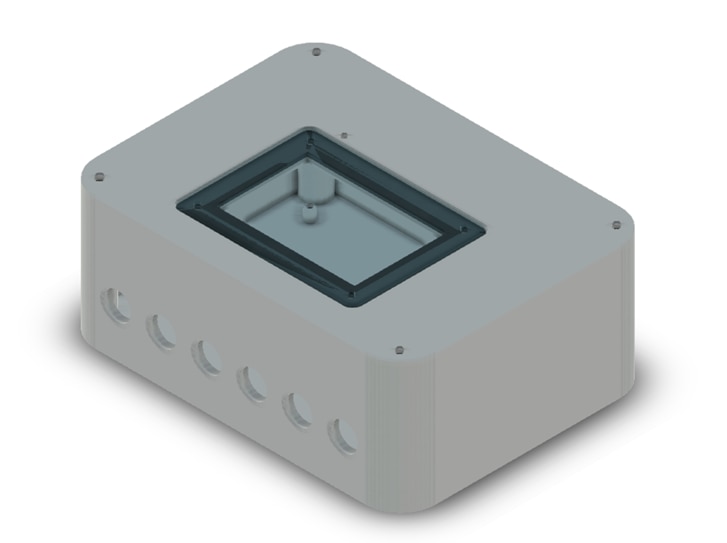

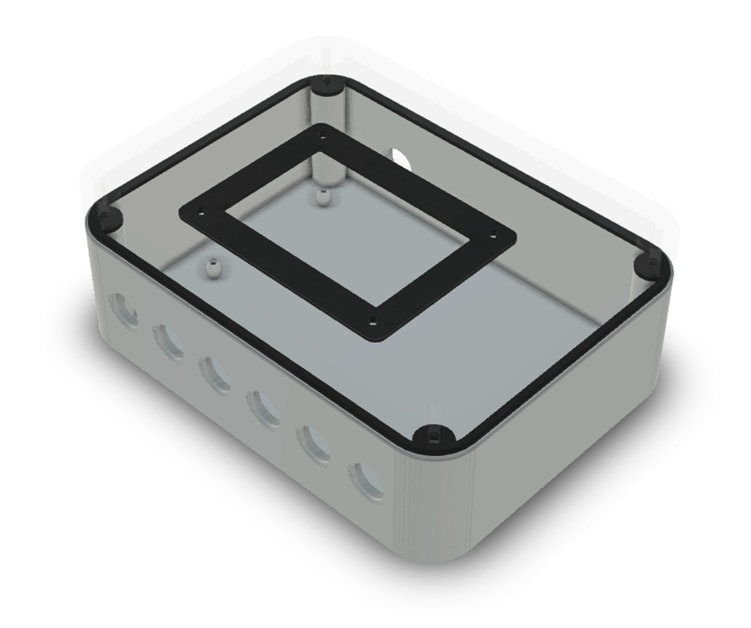

The mounted PCB is put in a PTFE porous membrane housing to prevent the electronic part from corrosion and shorts while ensuring constant airflow for measuring correct values. This is then connected via I2C cable to the controller which is encased from the water misters. A possible location for the controller would be in the edge or outside the mushroom shelter in a separate case. To ensure safety, the 3D printing team of Würth Elektronik helped with a customized 3D printed housing. Especially the display was a weak link before.

Figure 4: 3D printed housing

The only non-printed parts are cable entries for the housing. Gasket are printed with flexible material.

Figure 5: Assembled System Controller

After analyzing the cost structure, especially the CO2 sensor stands out as expensive. One approach could be to ditch the sensors and rely completely on a timer based control system. To lower CO2-level, an exhaust fan is used. To increase humidity and therefore decrease temperature, water misters are used. LED lights turn on and off every 12 hours. With these actuators, relays and sensors we made two exact same systems, only with different software. The tests were planned to take place in two similar, but separated mushroom growing tents. But for the initial parts, the setpoints have to be validated. Therefore, the first test run compares a simple timer based control system with the currently used manual procedure of experienced farmers.

The first software turns on the fans every 6 minutes for 220 seconds. Misters turn on every 6 minutes after the fans turn off for 18 seconds. Misters and fans do not work at the same time to increase efficiency. The fans take out the humid air so afterwards the misting increases the humidity again. These are estimated timespans and can be changed to get ideal surroundings. This also depends on the volume of the growing environment. The sensors of the timer based control system help with monitoring the change of parameters.

The second software turns on the fan if the measured CO2 level exceeds 2000 ppm and turns it off again if the level is below 600 ppm. To exchange air of the tent, the exhaust fan takes about 4 minutes. The misting system turns on at 80 % humidity. The duration of misting is based on a timer because humidity is a slow value to measure. It takes about 10 minutes to detect a change of humidity after misting. This mister sprays small water droplets into the air. The water has to evaporate to humidity to get detected by the sensor.

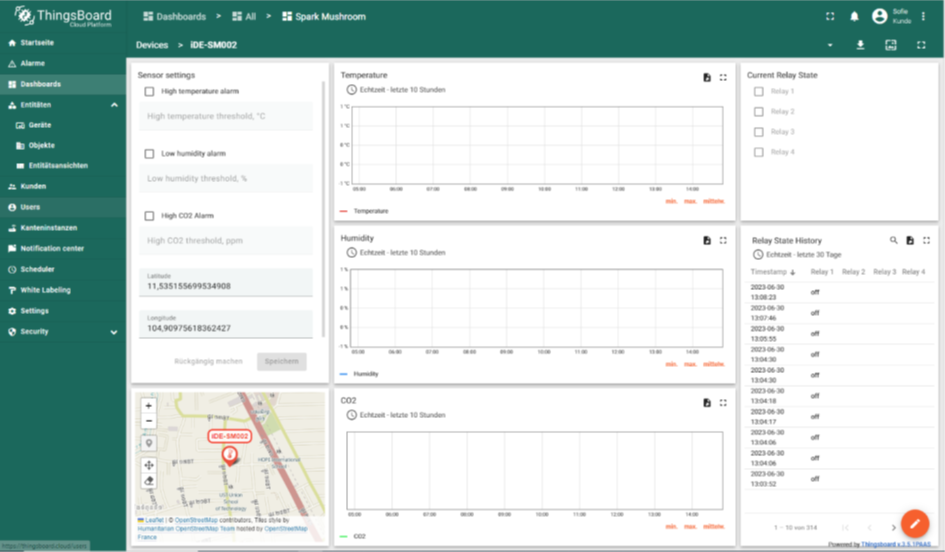

The monitoring, next to the display, is also possible via cloud access. All measured data is uploaded to ThingsBoard. ThingsBoard is a platform which allows users to create and monitor IoT projects. The control system only needs to connection to WiFi (Setebos-I Radio Module 2.4 GHz with Proprietary and Bluetooth® LE 5.1 Radio Protocol). The data on the dashboard is then updated in real time.

Figure 6: Dashboard of thingsboard cloud

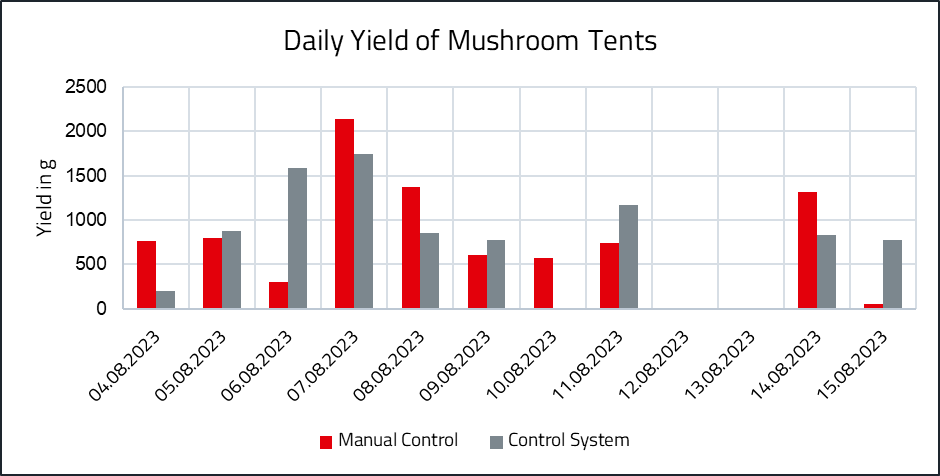

The diagram below shows the daily yield of the two different mushroom tents respectively. On 12th and 13th of August was no yield collected due to weekend. As you can see, the traditional method showed more yield outcome than the control system. Also the fruitbodies look more dried out. There is one step which should be implemented to increase yield and improve appearance of the mushrooms. The farmers spray mushrooms directly with water to prevent them from drying out. This was implemented for the second test run.

Figure 7: Daily yield of 50 substrate bags

The bar graph in Figure 6 shows cumulative yield per day of 50 mushroom substrate bags. The red pillars represent yield of the manual control tent and gray pillars represent yield of the control system tent. On 12th and 13th of August was no yield collected due to weekend. After one month, the cumulative mass of harvested mushrooms is 18.49 kg for traditional methods and 18.37 kg for the control system. While the results after four weeks of growing were surprisingly similar, the potential for improvement with the control system is significant. With more experience and fine-tuning of the setpoints, the control system is expected to surpass traditional farming methods.

Implementing Industrial Internet of Things (IIoT) technology is crucial for maximizing yield through continuous monitoring. Unlike a simple timer, an IIoT-based control system can show to real-time changes in the environment, such as a sudden drop in humidity when someone opens the door. This adaptability ensures optimal growing conditions at all times, leading to a substantial increase in yield and overall efficiency. By leveraging IIoT, farmers should achieve more consistent and higher-quality harvests, ultimately boosting their income and improving their livelihoods.

To conclude, the implementation of the WSEN-HIDS sensor for temperature and humidity was a key factor which changed the direction of the project. With the correctly selected parts, the system is equipped for challenging environmental factors. The control system is now in field tests with farmers. The first reception is positive. The interface is designed as simple as possible with pictograms and local Khmer language.

Find out more about the project: https://designawards.core77.com/Design-for-Social-Impact/130663/Smart-Mushroom-Growing-Kits-to-Boost-Rural-Entrepreneur-Livelihoods-in-Cambodia

Top Comments