Application Note

REDFIT SKEDD Crimp Connector #PLUGTHEPOWER

ANE017 by Moritz Jakob & Andreas Aigner

01. INTRODUCTION

SKEDD is a technology developed by Würth Elektronik that allows connectors to contact directly with the printed circuit board without soldering. The combination with the crimp technology of the REDFIT Crimp SKEDD Connector offers significant advantages over soldered connectors.

02. CORE OF THE SKEDD TECHNOLOGY

The core of SKEDD technology consists of innovatively designed stamped contacts that provide an electrically stable connection directly within the plated through-holes of the printed circuit board. The mechanical preload generated during contact insertion ensures a stable electrical connection even under high vibration conditions. The use of high-performance alloys as contact materials enables a high normal contact force, which ensures reliable electrical connectivity under demanding mechanical conditions. Thus, SKEDD technology provides a stable electrical connection.

Difference from Press-Fit Technology with Solid Pins

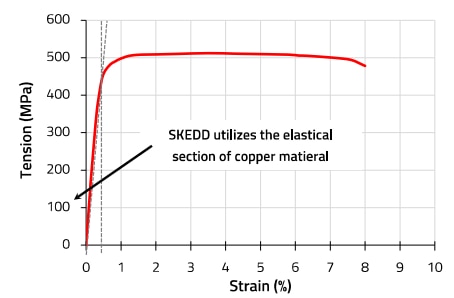

In conventional press-fit connections using solid pins, the high forces applied during the joining process create a permanent, non-detachable connection between the contact partners. The plated through-hole of the printed circuit board adapts to the contact because of the press-in process. With SKEDD technology, no permanent deformation of the plated through-hole occurs. Only the SKEDD forks are preloaded and return to their original position after the connection is released. In other words, SKEDD utilizes the elastic range of the copper material (see Figure 1). A sufficiently large elastic range is essential for compensating hole and positional tolerances while maintaining an adequate normal contact force. This range is influenced by the selection of suitable materials and by a design that provides an optimal balance between stiffness and elasticity.

Figure 1: Tension and elongation behavior of copper material

03. SKEDD AS A CRIMP CONTACT

With the REDFIT Crimp SKEDD Connector, this technology has been further developed for use in PCB power supply applications to achieve higher current-carrying capacity while maintaining high contact stability.

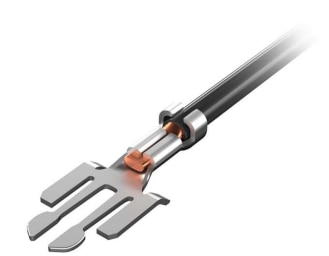

In addition to improved electrical properties, the mechanical stability has also been raised to a new level. Thanks to SKEDD technology, both inserting the contact into the housing and the connector into the printed circuit board can be done manually without tools. This eliminates the need for both the soldering process and a mating connector. For the connection to the wire, well-established crimping technology is used. Figure 2 shows the REDFIT Crimp system with contact and connector in the unmated condition.

Figure 2: SKEDD Crimp contact

04. ELECTRICAL PARAMETERS

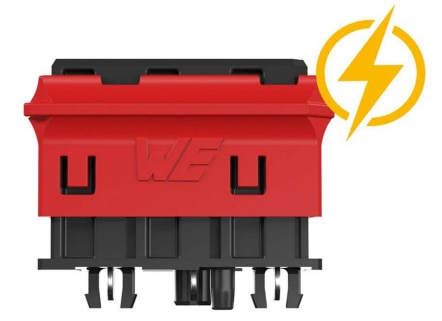

As mentioned previously, the new REDFIT version is designed for power supply applications on the printed circuit board. With a current-carrying capacity of 16 A at an operating voltage of 400 VAC, it is also ideally suited for mains power applications.

Figure 3: REDFIT Crimp for power supply

05. MECHANICAL STABILITY

In industrial applications, mechanical stability is of high importance in addition to electrical properties.

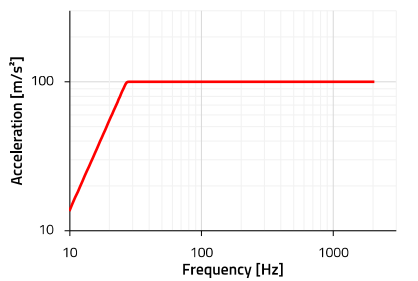

Thanks to the newly developed and patented mechanical locking mechanism, forces up to 10 g can be withstood without mechanical or electrical failure. Conventional connectors are typically tested at 5 g over frequencies from 10 to 55 Hz. Figure 4 shows the process of how the connector is tested for vibration. The acceleration acts on the connector for a duration of 7.5 hours with up to 10 g. This ensures that no mechanical or electrical failures occur under high mechanical stress. A sinusoidal frequency sweep from 10 to 2000 Hz is tested.

Figure 4: Vibration curve 10 g (10 to 2000 Hz)

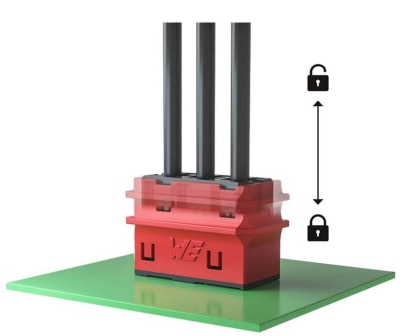

During the development of the active locking mechanism, special emphasis was placed on user friendliness. After manually inserting the REDFIT connector into the printed circuit board, the collar is simply pushed down to its lowest position. In this position, a locking dome secures the latching tabs in the PCB, providing both tactile and audible feedback to the user. This ensures stable mounting, making the connector suitable even for mechanically demanding applications.

Figure 5: Positive feedback when locking with slider

The patented locking mechanism of the connector on the printed circuit board combines the mechanical and electrical connection within a single plated through-hole. This saves space on the PCB, allowing for a more compact connector design. As a result, the REDFIT Crimp also meets the requirements of miniaturization.

Figure 6: Locked connector

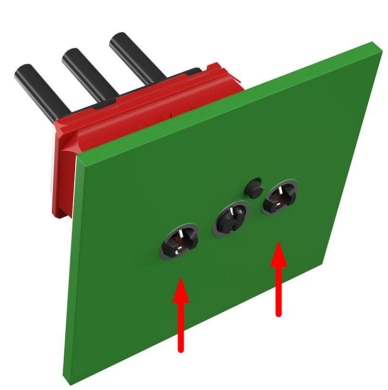

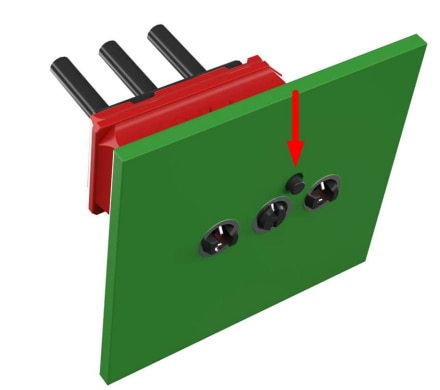

An additional plastic pin prevents accidental reverse polarity of the contacts. An extra marking on the housing indicates the position of PIN 1 in ascending order.

Figure 7: Plastic pin assures correct polarity.

06. PCB LAYOUT The REDFIT

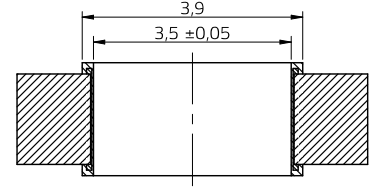

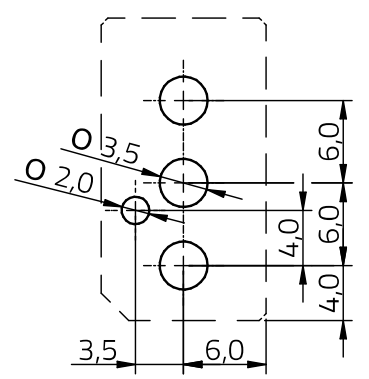

Crimp connector requires a PCB thickness of 1.6 mm. For optimal electrical and mechanical connection, the tolerances used for press-fit technology should be applied during PCB manufacturing. The PCB plating can be done with chemical tin, ENIG, or HAL. The pad size is negligible, as the contact is formed within the sleeve. However, the pad is required for PCB production. Thus, the annular ring size can be minimized. The drill hole specifications are shown in Figure 8. The plated through-hole should have a final diameter of 3.5 mm.

Figure 8: Drill hole and plating specification (in mm)

Figure 9 shows the recommended layout for a REDFIT Crimp with three pins. Since the mechanical fixation also occurs within the plated through-hole, no additional mounting points are required. Depending on the application, the REDFIT Crimp can also be mounted in the opposite insertion direction. In this case, the layout simply needs to be placed on the desired side of the PCB.

Figure 9: PCB Layout (in mm)

07. AVAILABLE VERSIONS

The REDFIT Crimp is available in configurations from 1 to 5 pins. Visual coding can be achieved using differently colored connector collars. The collars are available in red, blue, yellow, black, and white.

Figure 10: Color-Coded to the number of pins

08. CONCLUSION

The REDFIT Crimp SKEDD connector can be used flexibly in mechanically and electrically demanding applications. It is mounted directly onto the printed circuit board by hand, eliminating the need for both the soldering process and a mating connector. SKEDD technology can supply current of up to 16 A to fully SMT-populated PCBs. Depending on the layout, mounting in the opposite insertion direction is also possible. The entire SKEDD product range at a glance.

I M P O R T A N T N O T I C E

The Application Note is based on our knowledge and experience of typical requirements concerning these areas. It serves as general guidance and should not be construed as a commitment for the suitability for customer applications by Würth Elektronik eiSos GmbH & Co. KG. The information in the Application Note is subject to change without notice. This document and parts thereof must not be reproduced or copied without written permission, and contents thereof must not be imparted to a third party nor be used for any unauthorized purpose. Würth Elektronik eiSos GmbH & Co. KG and its subsidiaries and affiliates (WE) are not liable for application assistance of any kind. Customers may use WE’s assistance and product recommendations for their applications and design. The responsibility for the applicability and use of WE Products in a particular customer design is always solely within the authority of the customer. Due to this fact it is up to the customer to evaluate and investigate, where appropriate, and decide whether the device with the specific product characteristics described in the product specification is valid and suitable for the respective customer application or not. The technical specifications are stated in the current data sheet of the products. Therefore the customers shall use the data sheets and are cautioned to verify that data sheets are current. The current data sheets can be downloaded at www.we-online.com. Customers shall strictly observe any product-specific notes, cautions and warnings. WE reserves the right to make corrections, modifications, enhancements, improvements, and other changes to its products and services. WE DOES NOT WARRANT OR REPRESENT THAT ANY LICENSE, EITHER EXPRESS OR IMPLIED, IS GRANTED UNDER ANY PATENT RIGHT, COPYRIGHT, MASK WORK RIGHT, OR OTHER INTELLECTUAL PROPERTY RIGHT RELATING TO ANY COMBINATION, MACHINE, OR PROCESS IN WHICH WE PRODUCTS OR SERVICES ARE USED. INFORMATION PUBLISHED BY WE REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT CONSTITUTE A LICENSE FROM WE TO USE SUCH PRODUCTS OR SERVICES OR A WARRANTY OR ENDORSEMENT THEREOF. WE products are not authorized for use in safety-critical applications, or where a failure of the product is reasonably expected to cause severe personal injury or death. Moreover, WE products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc. Customers shall inform WE about the intent of such usage before design-in stage. In certain customer applications requiring a very high level of safety and in which the malfunction or failure of an electronic component could endanger human life or health, customers must ensure that they have all necessary expertise in the safety and regulatory ramifications of their applications. Customers acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any use of WE products in such safety-critical applications, notwithstanding any applications-related information or support that may be provided by WE. CUSTOMERS SHALL INDEMNIFY WE AGAINST ANY DAMAGES ARISING OUT OF THE USE OF WE PRODUCTS IN SUCH SAFETYCRITICAL APPLICATIONS.

DIRECT LINK

ANE017 | REDFIT SKEDD Crimp Connector

USEFUL LINKS:

Application Notes : https://we-online.com/en/support/knowledge/application-notes

Services: https://we-online.com/en/products/components/service

Contact : https://we-online.com/en/support/contact

CONTACT INFORMATION

Würth Elektronik eiSos GmbH & Co. KG

Max-Eyth-Str. 1, 74638 Waldenburg, Germany

Tel.: +49 (0) 7942 / 945 – 0

Email: appnotes@we-online.de