Support Note

Why does the capacity of MLCCs change?

SN011 BY FRANK PUHANE

1 Overview about Class 1 and Class 2 MLCCs?

Basically, two types of MLCCSs can be differentiated: capacitors, which are constructed of class 1 or class 2 ceramics. These vary in several aspects as shown in table 1.

Table 1: Overview of the current technical status of the Würth Elektronik eiSos’ ceramics

The properties and tolerances of the different ceramic classes are defined by an IEC or EIA coding (for further information see AppNote ANP062). Depending on the application, a certain amount of capacitance must be available to achieve the desired performance in such applications as filters. It is therefore important to compare the properties of the individual components to ensure the desired behavior when used in the application. It should also be mentioned that with high-capacitance MLCCs, the high capacitance is only available with the drawback of increased aging and thus a greater loss of capacitance due to temperature and voltage.

2 Definition of aging

Aging is a process in which certain properties change over time. Ferroelectric materials such as barium titanate are also subject to this process. The crystal structure of the dielectric (in this case barium titanate) changes with temperature and also with time. This is considered aging, since the capacity changes or, more precisely, is reduced by this event. Another result of aging is the increase in the loss factor, which becomes steadily larger. Aging is usually described by a percentage loss of capacitance per decade of time. It is in the range of ~6% after 1000 h for X5R ceramics and ~2.5% after 1000 h for X7R ceramics per decade hours (1-10, 10-100, 100-1000, ...). After realigning the crystal lattice (e.g. by a temperature process that can be repeated as often as desired), aging leads to a loss of capacitance as shown in Figure 1. The process of aging is logarithmic and decreasing with time. It although appears linear on charts when using logarithmic scales.

Figure 1: Capacity loss vs. operating time

3 Why does aging exists for barium titanate?

The permittivity of barium titanate is defined by the polarizability of the material. Further ferroelectric domains are formed by aging. The spontaneous polarization direction changes in such a way that not all dipoles can be polarized "well". The dipoles of two adjacent domains no longer point in the same direction. The result is the reduction of the capacitance. The solution: reformation of the material. The effect of aging is influenced by time, temperature and voltage. Since barium titanate is a ferroelectric material and, like ferrite, has electrical domains, these domains divide with the factor time and thus reduce the capacitance, see Figure 2.

Figure 2: Change of the internal structure

By tempering, the so-called preheating process (heating the material above the Curie temperature), the existing domains dissolve. Below the Curie temperature, the material then forms new large domains again, which in turn results in a high capacity. The thermal movement in the crystal lattice caused by the annealing process prevents the dipoles from aligning completely when an electric field is applied, thus reaching a kind of saturation.

4 How can aging be stopped?

The dielectric used in Class 2 MLCCs has ferroelectric properties. These material properties change when the Curie temperature is exceeded (as with ferromagnetic materials). Above this temperature, the dielectric has a highly symmetrical cubic crystal structure, while below the Curie temperature; the crystal structure has a less symmetrical (tetragonal) structure. The transition from the different phases (cubic to tetragonal etc.) always results in a maximum value of permittivity over this temperature range. To achieve a stable state, the atoms in the crystal lattice move under the influence of thermal vibration for a long time, even after the dielectric has cooled down below the Curie temperature (more and more domains are formed). However, when the capacitor is heated to a temperature above the Curie temperature, aging takes place, i.e. the capacity lost due to aging is regained and aging begins again from the point at which the capacitor cools down again. This temperature is ~125°C for barium titanate. Depending on how long the Curie temperature is exceeded, this results in the capacitance value that is set. According to the data sheet, the recommendation for preheating at 150°C is 1 hour. By this thermal treatment, the maximum 100% capacity of the component can be restored.

5 Effects of aging for the application

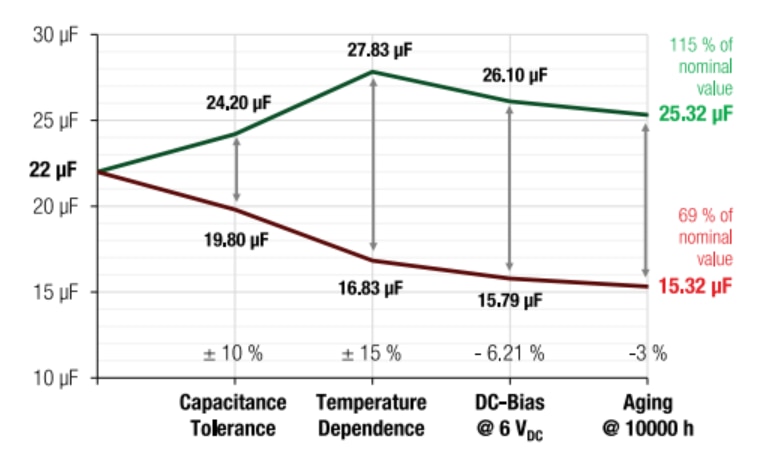

In a real application, which contains voltage and is operated at a certain ambient temperature, a reduction in capacity over time must generally be foreseen when using MLCCs. This is unavoidable and is caused by the base material used for Class 2 ceramics. It is now up to the design of the capacitor to compensate for this capacitance loss. A 100% test is performed after manufacture to ensure that all tolerances are met. Depending on storage time and storage conditions, these values may change over time. Due to the heat influence of the soldering process, the aging process is reset (see appendix, example measurement and reflow soldering process for a MLCC with the DateCode 2014). In applications where stable capacitance values are required, aging must be considered or a Class 1 MLCC must be used. If capacitors are used as output capacitors (e.g. in switching regulators), the effect of aging can be best compensated for, as in this case the capacitance fluctuations are in the low single-digit range and therefore have no negative effect on the function of the circuit. The resulting capacitance of an e.g. 22 µF X7R MLCC with all dependencies is shown in figure 3.

Figure 3: Real capacity considering all dependencies

6 Conclusion

The aging is recorded at room temperature (around 20 °C) and ~0 V as applied voltage. At room temperature and ~0 V ceramic capacitors have almost no temperature, DC bias and frequency influences that could influence aging. Below the Curie temperature and after applying a voltage, the existing ferroelectric properties polarize the molecules in a defined manner. The cubic structure becomes a tetragonal structure, which leads to a decrease in permittivity and thus in capacity. What now leads to aging? If the crystal structure of the ceramic is left at room temperature without load, randomly oriented domains are formed in which, in turn, non-directional dipoles are formed, which have a negative influence on the permittivity. These randomly oriented domains "grow" faster at first and then develop more slowly. Therefore, the loss of capacity is shown logarithmically. When a voltage is applied and the temperature is increased, the formation of randomly oriented domains slows down, since the dipoles are aligned in a defined manner by the electric field. In practice, this means that aging as shown in Figure 1 is a “worst case” figure. Since the decrease in capacity via DC bias and temperature is significantly higher than the expected aging, this is assumed a fixed value.

7 Appendix

Figure 4 shows the capacitance measurement of the 885012108001-> 4.7µF / 6.3V / 1206 ceramic capacitor from the production window DateCode 2014. The grey dots shows the capacitance measurement before the reflow process. The red dots shows the capacitance measurement after the reflow process. The soldering profile is shown in Figure 5. The temperatures and times of the soldering process is shown in Figure 4. The datasheet can be viewed via the following link. The electrical specification such as impedance, ESR, DC bias, etc. are available via the REDEXPERT online tool.

Figure 4: Capacitance measurement before (grey dots) and after (red dots) the reflow process

Figure 5: Soldering profile from the data sheet of the 885012108001

Table 2: Temperature profile for the reflow process from the data sheet of the 885012108001

IMPORTANT NOTICE

The Application Note is based on our knowledge and experience of typical requirements concerning these areas. It serves as general guidance and should not be construed as a commitment for the suitability for customer applications by Würth Elektronik eiSos GmbH & Co. KG. The information in the Application Note is subject to change without notice. This document and parts thereof must not be reproduced or copied without written permission, and contents thereof must not be imparted to a third party nor be used for any unauthorized purpose. Würth Elektronik eiSos GmbH & Co. KG and its subsidiaries and affiliates (WE) are not liable for application assistance of any kind. Customers may use WE’s assistance and product recommendations for their applications and design. The responsibility for the applicability and use of WE Products in a particular customer design is always solely within the authority of the customer. Due to this fact it is up to the customer to evaluate and investigate, where appropriate, and decide whether the device with the specific product characteristics described in the product specification is valid and suitable for the respective customer application or not. The technical specifications are stated in the current data sheet of the products. Therefore the customers shall use the data sheets and are cautioned to verify that data sheets are current. The current data sheets can be downloaded at www.we-online.com. Customers shall strictly observe any product-specific notes, cautions and warnings. WE reserves the right to make corrections, modifications, enhancements, improvements, and other changes to its products and services. WE DOES NOT WARRANT OR REPRESENT THAT ANY LICENSE, EITHER EXPRESS OR IMPLIED, IS GRANTED UNDER ANY PATENT RIGHT, COPYRIGHT, MASK WORK RIGHT, OR OTHER INTELLECTUAL PROPERTY RIGHT RELATING TO ANY COMBINATION, MACHINE, OR PROCESS IN WHICH WE PRODUCTS OR SERVICES ARE USED. INFORMATION PUBLISHED BY WE REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT CONSTITUTE A LICENSE FROM WE TO USE SUCH PRODUCTS OR SERVICES OR A WARRANTY OR ENDORSEMENT THEREOF. WE products are not authorized for use in safety-critical applications, or where a failure of the product is reasonably expected to cause severe personal injury or death. Moreover, WE products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc. Customers shall inform WE about the intent of such usage before design-in stage. In certain customer applications requiring a very high level of safety and in which the malfunction or failure of an electronic component could endanger human life or health, customers must ensure that they have all necessary expertise in the safety and regulatory ramifications of their applications. Customers acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any use of WE products in such safetycritical applications, notwithstanding any applications-related information or support that may be provided by WE. CUSTOMERS SHALL INDEMNIFY WE AGAINST ANY DAMAGES ARISING OUT OF THE USE OF WE PRODUCTS IN SUCH SAFETY-CRITICAL APPLICATIONS.

DIRECT LINK

SN011: Why does the capacity of MLCCs change

USEFUL LINKS:

Application Notes : https://we-online.com/en/support/knowledge/application-notes

Services: https://we-online.com/en/products/components/service

Contact : https://we-online.com/en/support/contact

CONTACT INFORMATION

Würth Elektronik eiSos GmbH & Co. KG

Max-Eyth-Str. 1, 74638 Waldenburg, Germany

Tel.: +49 (0) 7942 / 945 – 0

Email: appnotes@we-online.de