Taking A Closer Look at Mechanical Components and Cleaning Processes

By Jasmin Hsu

Over the years, we have frequently received questions regarding the washing process of mechanical switches.

We have observed that washing has become a standard part of the production process for customers. Washing the PCB helps remove residues on the PCB to avoid corrosion, short circuit or maybe the customer has afterward another coating or potting processes.

And in the market, we also see different definitions like dustproof, waterproof, IP-rated, washable.

But in most of the times, manufactures still do not allow customer to wash their mechanical components.

The second characteristic numeral indicates the degree of protection provided by equipment against ingress of water. The tests for the second characteristic numeral, except for numeral 9, are carried out with fresh water at temperature range of 15 °C to 35 °C. The actual protection may not be sufficient if cleaning operations involve high water temperatures outside the requirements of the second characteristic numeral and/or cleaning solvents are used.

So far, based on what we know, there isn't a single standard for the cleanability of general electronic components. One of the reasons is that these standards (AEC standards, IEC standards) ensure component reliability under various conditions, but cleanability is not their primary focus. IPC standards define cleanliness requirements for printed circuit boards (PCBs) and assembled boards, but these standards apply for cleaning after manufacturing, not for the component's ability to withstand cleaning.

Why might mechanical parts be not suitable for the washing process?

We need to break this question into 2 aspects.

When you search for IPx7, you can find a lot of information related to IEC 60529. Behind each characteristic numeral, there is a definition of how the enclosure must be tested with water (e.g. spray, submersion). It is important to note is that: the test is performed using only water.

However, in the actual production processes, the cleaning/washing process is carried out using a combination of cleaning agent, defoamer & water. Different water temperature and water pressures depending on actual practice.

So, if the test conditions of IEC 60529 are so different from the actual cleaning process, can we really say that IPx7 parts are Washable?

From another perspective, the term “mechanical switches” is already quite self-explanatory..

They are built from various mechanical spare parts to become a mechanical switch.

As an example, imagine stacking Lego bricks on each other. If you put them into water, you will see a lot of water bubbles will be popping up indicating there are air gap between the Lego bricks.

Or if you build a house without putting cement between the bricks, wind and water will pass easily into the house, right?

With the two examples above, we hope we can give you a deeper dive into our today’s topic.

To build a house, we need bricks and cement to seal the air gaps. Similarly, for a mechanical switch, we need also some additional protection or ingredients to the component to make it more protected from fluid ingress. And recent solution is to use silicone rubber no matter in which form or shape and the function of the rubber is to is to be designed in such a way that it closes or minimizes the air gap between the spare parts

But does using silicone rubber automatically mean the switch is airtight ?

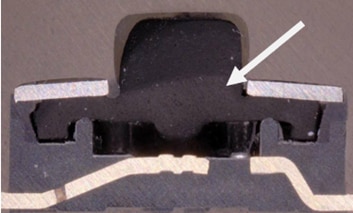

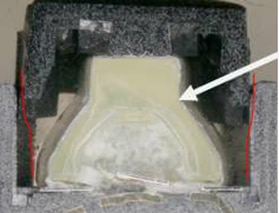

Take a look on these two pictures: they show two different internal structures both using silicone rubber inside a switch. One silicone rubber is placed on the gap between the cover and the base., In the other , it is placed above the stationary contact to protect it .

Which one do you think performs better when water flows from top to bottom?

(Picture on right:, air gap on the red line areas between cover and base)

So, even when silicone rubber is used, it does not mean the switch is sealed.

What we want to express is that, that even with silicone rubber inside the switch, without a proper design to close or tighten the possible air gap it is not possible to achieve the sealing function for a mechanical switch.

Conclusion :

- IP testing is performed using only water, which is different from what is used in the actual cleaning process.

- Usage of silicone rubber improves protection but does not mean it is sealed.