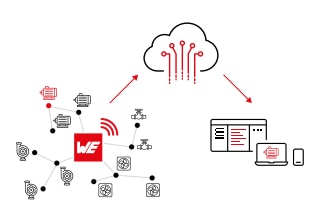

User application industrial IoT

Wirepas Mesh is the perfect fit for Industrial IoT

The manufacturing industry has started seeing a growing need for monitoring the condition of their assets and to perform predictive maintenance if needed. The challenge is that smart industries require an industrial IoT connectivity solution, a self-healing mesh network that can handle a demanding radio environment.

Predictive Maintenance

Machines, devices and equipment in production are lasting investments and keeping them operative is key. The sensors measure the condition data for the machines, devices and equipment and trigger predictive maintenance if needed. This reduces the need for multiple days of production halt to a few hours of maintenance.

Leakage Control

Pipes, ducts and vents carry and control many gas and liquid in production and from production plants to use. Monitoring and controlling valves and levers with sensors to ensure there are no leakages saves both money and the environment. The high number of sensors require a robust IoT connectivity to operate securely.

Monitoring and Measuring of Material Levels and Condition

Tanks, containers, vessels and sewage systems may carry dangerous liquids, gasses or material and the use levels need to be ensured to make sure safety and productivity is in check. Sensors may also keep tabs on for example safe temperature or ambient light levels to prevent accidents from happening.

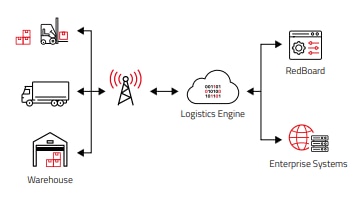

RedLore – Container Tracking

RedLore Smart Sensors can be used in a large range of applications thanks to the wide variety of built-in sensors. The Smart Sensors have the Wirepas Mesh Network Communication protocol inside: Every device is a wireless router and can act as a repeater for other nodes. As a result very large physical networks with 1000’s of nodes can be built as long as every node can connect to a node which is closer to the gateway. At the same time every node remains low power and can work uninterruptedly for years on a small battery. Different variants are available, each with different sensor sets and a long-life industrial LiSOCl2 battery for up to 10 years of battery life. The sensing parameters (e.g. update rate) can be changed to suit the application needs. The Smart Sensors send their data to a gateway. The accompanying Mobile App connects through the built-in NFC ‘tap’- interface, allowing configuration and diagnostics of a device. The same functions are available from the gateway using the Remote Functions API.

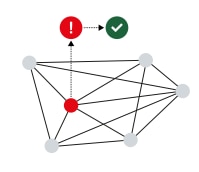

Condition Monitoring

Condition monitoring can be expensive - which is why up to 95 percent of all aggregates in a production plant aren't monitored or are monitored sporadically, which leads to high risks for unplanned downtimes.

With a condition monitoring system you can monitor hundreds of aggregates within a few hours. Thus monitoring is simple, fast and costefficient.

The expandable system works for almost all aggregates and detects potential damage, imbalances and misalignments already weeks in advance. The final end solution can consist of:

- Wireless sensors to monitor machine and equipment data

- A gateway that receives the sensor data and transmits it into the cloud

- A digital service that evaluates this data and provides professional error analyses - comfortably via smartphone or desktop application

If you want to read more find here the whole Product Guide.