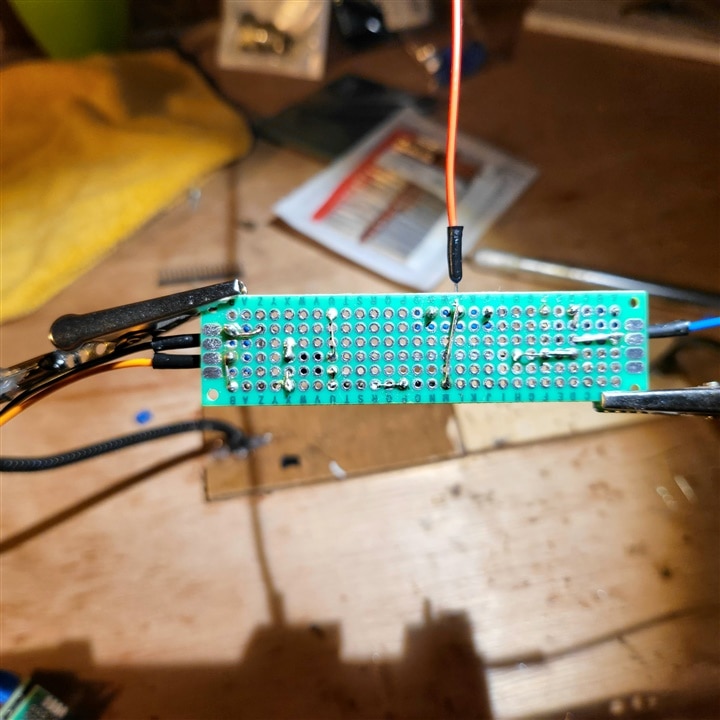

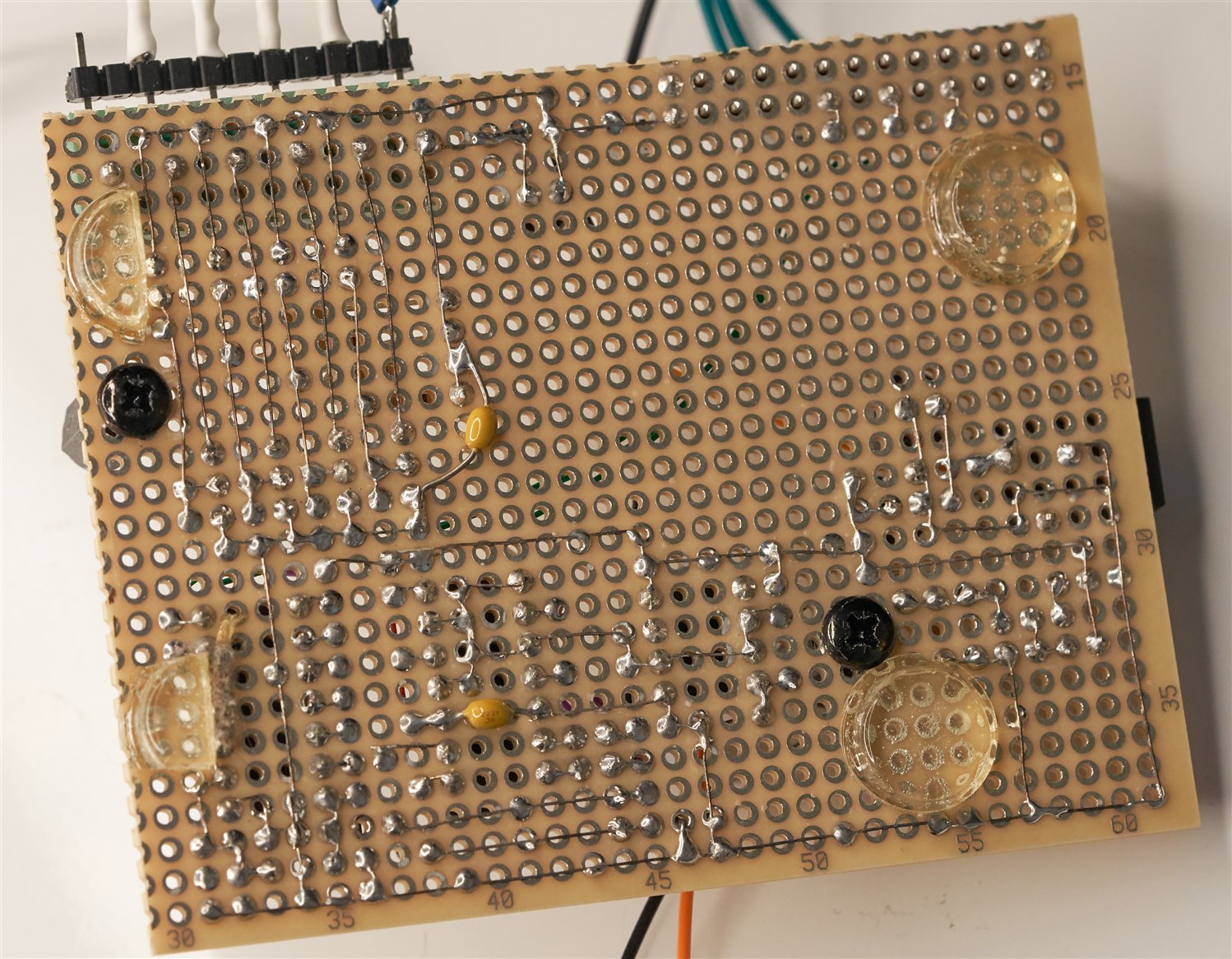

Can you review this circuit layout. Using Rasp pi to drive a high end LED strip. 24v mini 0402 LED.

I am experiencing a power leak on the board i built. I believe i need resistance after my optocoupler on the Pi. side.

With the high voltage I am looking to protect the pi while still safely operating the strip.

i have changed 2 things on this board since the picture. I now have all grounds on ths Zenner Diode side connected to power supply ground and I decreased the Resistor from. 100k to 10k on the advise of Open Ai