RoadTest: METCAL GT120-HP-T6 Soldering Station

Author: john.porter

Creation date:

Evaluation Type: Connectors & Cable

Did you receive all parts the manufacturer stated would be included in the package?: True

What other parts do you consider comparable to this product?: Weller WE1010NA, Hakko FX-100. A Weller WESD51 used for comparison in this review.

What were the biggest problems encountered?: Awkward fit of the tip on the iron, software bug detected, unit failed post evaluation.

Detailed Review:

One of the top essential tools for any electronic engineer, engineering student or hobbyist is the soldering iron. Many electronic projects and repairs require this tool and I have had several in my time. Considering it’s importance on the bench, I am excited to test and review one of the recent additions to the Metcal lineup, the Metcal GT90-HP-T4 Soldering Station.

Metcal is respected for delivering high end benchtop soldering solutions. The GT series is a recent addition, and fresh territory for Metcal. With the GT series they now include inductive heating in soldering stations with adjustable temperature, technology that is commonly found in research labs and production lines as in other Metcal models. The GT90 supplies 90 Watts of variable soldering heat and positions itself as a top choice for benches that require a reliable and quick iron.

I have set the GT90 through its paces, completing hundreds of soldering connections, and making comparisons along the way with a 50-Watt Weller WESD51 which has been my soldering workhorse for the past two decades.

I have posted a blog (here) where I introduce the GT90, and describe the package contents through some unboxing photos. For this review, Element 14 and Metcal included a generous choice of iron tips to experiment with, I did tend to favor the 1mm chisel tip for most applications (center in the below photo).

The GT90 heats up very quickly, holds temperature well and is easy to use. It is a solid soldering station for research, development, production, or the demanding hobbyist. I discovered some details that I would like to see improved as I describe later in this review.

Specification and cost comparison

The Metcal GT90 has no known competition for variable temperature using the fast inductive heating system, a unique combination that sets the GT series soldering stations apart and something to bear in mind while reviewing the above chart. The chart compares key features between the Metcal GT90, Weller WESD51 and two similar Weller and Hakko products. A green gecko highlights which soldering stations have the top result.

Physical Characteristics

Setup of the Metcal GT90-HP-T4 is easy and straight forward. The handset is assembled by inserting the included cartridge, adding a tip (not included), securing the assembly with the provided retainer. An additional retainer is included to allow for Metcal’s GTU series ultrafine fixed tip cartridges however the GTU series does not appear to be available just yet. The handpiece snaps securely to the metal base with a din connector, the five-foot burn-proof cord is soft, flexible and resists tangles. A silicone pad is included to allow you to change the tip quickly without burning your hands.

The work stand is nicely set out, enabling easy access to the handset, sponge, brass wool, and tips. The stand can be quickly disassembled to clean up any solder bits. The handset rests in place nicely and can be quickly brought stand into service and back again, a nice feature.

The GT90’s height of 6-1/4” is nice, it’s brown surface prominent. Controls are easy to access. A USB port on the back allows for firmware upgrades or can deliver 5V, 0.5A to power other equipment.

Curiously, the 120-Watt, 48 Volt power supply is external to the base. While this does allow for easy replacement, it increases the footprint of the station if the power supply sits on the desk – this may be necessary considering the cord from the power supply is only four feet. Otherwise, the footprint is like the WESD51 as displayed in one of the following photos, along with a picture showing a handset comparison.

| {gallery}Metcal GT90 |

|---|

|

Metcal GT90 Ready to Assemble |

|

GT-WS Work Stand |

|

Metcal GT90 Work Stand With Handpiece |

|

GT-HP-T4UF Handpiece, GT-HC-T4 Heater Cartridge, GT4-CH0010S Chisel Tip, Retainer |

|

Assembled Handpiece |

|

Metcal GT-HP-T4UF vs Weller PES51 |

|

Footprint - Metcal GT90 vs Weller WESD51 |

I did encounter an issue with assembly that surprised me, the tip would sit slightly crooked. Perhaps it is just me and my inner need for all things to be straight, but it did get my attention. All tips had this issue over every tip change. It appears there may be too much clearance between the retainer edge and the tip. The retainer would screw in nicely with no-cross threading. While it was possible to correct by holding the tip centre while turning the retainer, this is not a practical solution. Performance was not noticeably affected by this issue, however the tip did seem to have better thermal transfer in some spots than others (more later).

I mentioned earlier that I soldered 100’s of connections during the testing of the Metcal GT90-HP-T4 solder station and went through nearly every tip. I built electronic kits (Christmas tree and clock), soldered random transistors, resistors, capacitors, d-type flip flop IC’s,14 AWG wire, copper plate and SMD parts. The Metcal GT90 managed all of these with ease. I even secured heavy 1 AWG booster cable to a booster clamp, though I knew I was pushing it with this test - it took seven minutes at 300°C to 400°C before I decided I had enough. Some pictures follow below:

| {gallery}Soldering Practice |

|---|

|

Holiday Spirit |

|

Practice Board with Various Components |

|

14 AWG Wire to Bare Copper Board |

|

Booster Cable |

|

Cleanup of a well used Metcal GT90 |

Performance

If I can sum up the performance, the Metcal GT90-HP-T4 is fast and powerful! It heats quickly, recovers fairly quickly, and holds temperature better than any soldering iron I have used.

I conducted a race between the GT90 and the WESD51 from an ambient 20°C to 300°C:

A second race was captured on a Keysight U5855A thermal camera!

And now the race, GT90 on the left, WESD51 on the right. At 1:53 I add solder to each iron. Spoiler … the GT90 wins handily.

The following photos and video demonstrate the GT90 start-up to 200°C using a K-type thermocouple and Keysight 34470A multimeter, blob of solder, along with multiple measure points on the thermal image of the same start up.

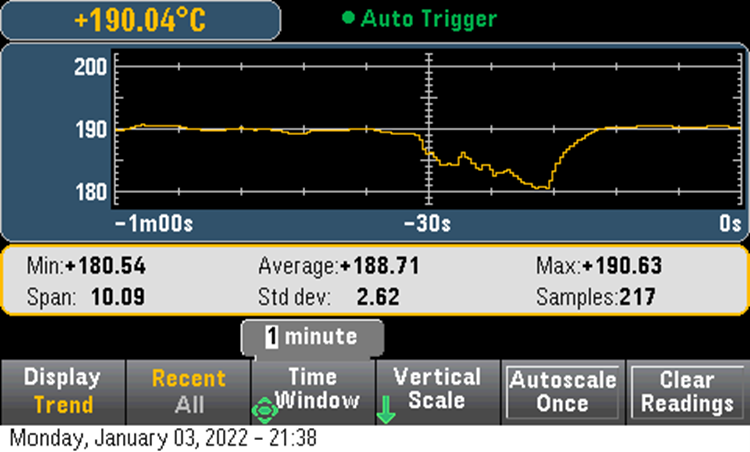

The recovery time of the GT90 was impressive. In this test, the iron is at 190°C. Solder is added for 14 seconds to create a nice blob of molten metal which drops the temperature by 10°C. Once the new solder is removed, the GT90 recovers temperature in approximately 5 seconds.

Accuracy

The GT90 heats quickly and holds it well, however irregularities were noted when conducting temperature measurements, with both the thermal camera and the K-type thermocouple.

You may have noticed in the videos that the thermal camera does not register the expected temperature near the end of the tip and is much lower. I found the thermal camera would consistently register lower temperature at the end of the tip and higher temperatures ¼” from the end of the tip, the higher temperatures would be closer to the set temperature.

Further, the tip of an iron is an exceedingly small space for a thermal camera to focus on. The minimum distance one can set for this camera is 1.0 meter, I was normally only a couple inches away. The closest measurements were obtained when the U5855A was set for emissivity of 0.70, typical for oxidized iron. These variables most likely impacted the thermal camera results.

A variation in temperature was also noted using the K-type thermocouple positioned at the soldering end of the tip. I found the set temperature would be closest to the thermocouple near 200°C however the measured and set temperatures would drift apart as the heat moved upwards. Solder was used to aid the transfer of heat from the tip to the probe. The thermocouple is a good test, but still leaves some variables.

|

GT90 Set Temperature |

Thermocouple |

Thermal Camera |

|

150°C |

155°C tip end |

137°C tip end - 160°C 1/4 tip |

|

200°C |

198°C tip end |

172°C tip end - 201°C 1/4 tip |

|

300°C |

272°C tip end |

245°C tip end - 292°C 1/4 tip |

|

350°C |

307°C tip end |

272°C tip end - 340°C 1/4 tip |

I tried one more test. The liquidus point of Sn63/Pb37 solder is 183 degrees. I wrapped the solder around the cold tip then turned the GT90 on, manually increasing the temperature 5 degrees at a time until I reached 185°C. The thermal camera confirmed the solder melts near the right temperature.

Software and Interface

The 2.5” white-on-blue display of the GT90 is easy to view however not as crisp as I would prefer. The menus are easy to navigate. The four buttons are large, easy to reach and provide access to the menu, temperature up/down and a return function. The GT90 makes it easy to change settings, superior to the WESD51 and its magnetic key with contorting power on sequences.

The menu is intuitive and easy to use. Settings are offered for:

I found setting the temperature to be relatively easy however noted two features I would like to see improved:

The current temperature is displayed nicely, however the set temperature does not normally appear except when performing an adjustment or if the administrative mode is active - where it is set in smaller text in the upper left corner as shown below. The WESD51 is similar however the Weller has a good excuse to hide the set temperature with it’s restrictive LED display. Including the set temperature display for typical use would be a helpful addition.

Holding one of the temperature buttons causes the temperature adjustment to speed up. This is ok however after approximately three seconds, it speeds up to a rate that makes it impossible to hit your target temperature and more likely to rail straight to the upper or lower limit of the station. A slower, incremental speed increase would be better. Compared to the dial on the WESD51, I much prefer the dial for easy rapid temperature changes.

I ran into a bug though. I guess it was not anticipated that someone may want to lock down changes with an administrative password, but may not choose to enforce specific pre-sets. This configuration would throw the GT90 into a very strange place, new characters would appear at the top with one seeming to cycle through the Ascii table. The iron would cool down on it’s own eventually displaying an error. Clearing the administrative password was a good first step but was not enough and would lock up the station. Resetting put things back to normal. I was able to duplicate this error consistently.

| {gallery}Bug |

|---|

|

Odd Characters in Upper Left 1/2 |

|

Odd Characters in Upper Left 2/2 |

|

Error and Lockup |

Upgrading to a new firmware is straight forward using the USB port, however no new firmware was available during this review - hopefully, one will be coming to address some of the enhancements I noted. I did ‘upgrade’ to the same version of software without issue (firmware V_0.00.96).

Conclusion

The Metcal GT90-HP-T4 Soldering Station heats up quickly, holds temperature very well and is comfortable and easy to use. It is a great soldering station for research, development, production or the demanding hobbyist. It is exciting to see inductive technology and the speed it delivers in a variable temperature soldering station.

It is not perfect. The tips and/or retainer design may need to be revised. The display would benefit from enhancement and there is a bug I hope to see addressed in a later firmware release.

Further and unfortunately, this soldering station suffered a critical failure following my evaluation and I am in contact with technical support. It is likely it will need to be sent in. Did I mention the GT90 comes with a one-year warranty?

The Metcal GT90-HP-T4 Soldering Station is a modern iron that I really enjoyed using and recommend for those looking for a soldering station that is fast and responsive. I am keeping my legacy iron in place for now, however will not hesitate to swap to the Metcal GT90 once it returns.

Want to own one? Purchase here at the Newark store!