RoadTest: NI Thermocouple Measurement Kit - Industrial Sensing

Author: neuromodulator

Creation date:

Evaluation Type: Test Equipment

Did you receive all parts the manufacturer stated would be included in the package?: True

What other parts do you consider comparable to this product?: NI hardware and software tightly integrated ecosystem is not really comparable to anything else.

What were the biggest problems encountered?: I did not encounter any problems.

Detailed Review:

Introduction

Data AcQuisition (DAQ) is the processes of measuring (sampling) physical properties through sensors so that they can be displayed, stored, or analyzed. A DAQ system typically consists of sensors connected to a DAQ measuring device that is connected to a computer. The sensor transduces physical properties (e.g, pressure, temperature, sound, weight) to electrical signals. The electrical signals are then conditioned (e.g., amplified and filtered) and then sampled by the ADC of the DAQ device and finally transmitted to the computer.

NI, formerly National Instruments is a company with more than 40 years of experience in development of automated test and automated measurement systems. NI is probably most known for their graphical programming environment LabVIEW, and their computer-controlled hardware. Within their hardware line, NI provides a wide variety of DAQs that can be classified in 4 categories depending on their technology.

PC-based DAQs do not require a chassis and connect directly to the PC through USB or PCIe. CompactDAQ (cDAQ) and CompactRIO (cRIO) are chassis-based modular solutions based on the the same module form factor. Some modules can be shared between cDAQ and cRIO but their main difference is that cRIO is based on a real-time processor plus an FPGA, while cDAQ relies on the host PC. PCI eXtensions for Instrumentation (PXI) systems are also modular systems based on the PXI standard, developed by NI in 1997, but nowadays supported by many vendors.

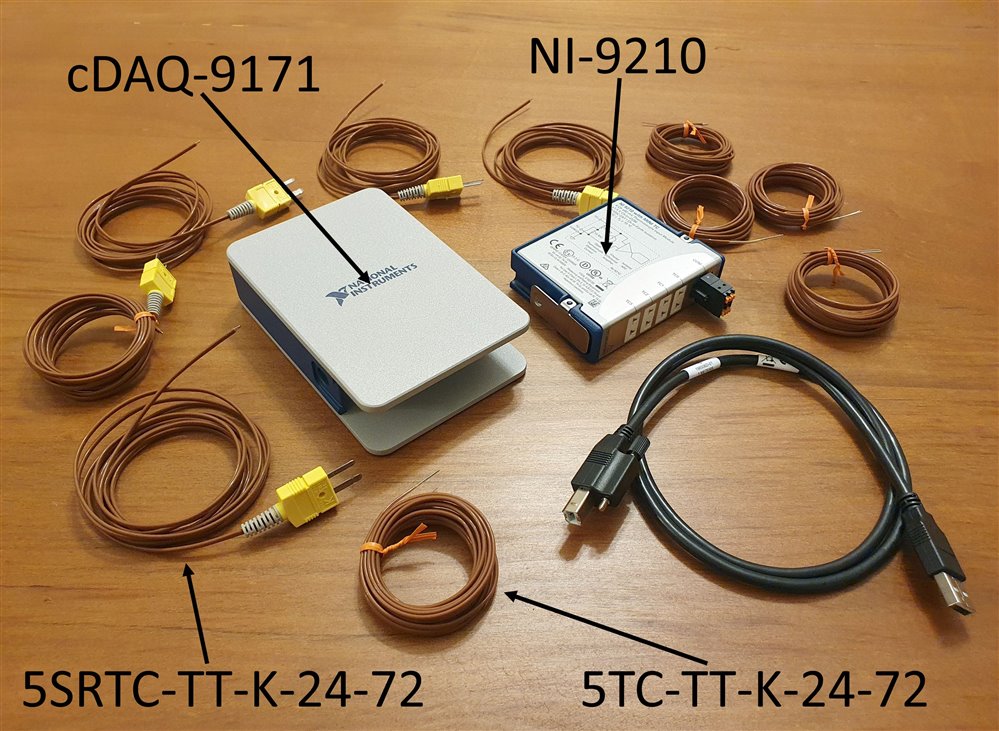

In this roadtest I will review the cDAQ-9171 one slot bus-powered USB Chassis, the NI-9210 temperature input module, 5 Omega 5SRTC-TT-K-24-72 thermocouples, and NI’s FlexLogger data logging and sensor configuration software.

The Kit

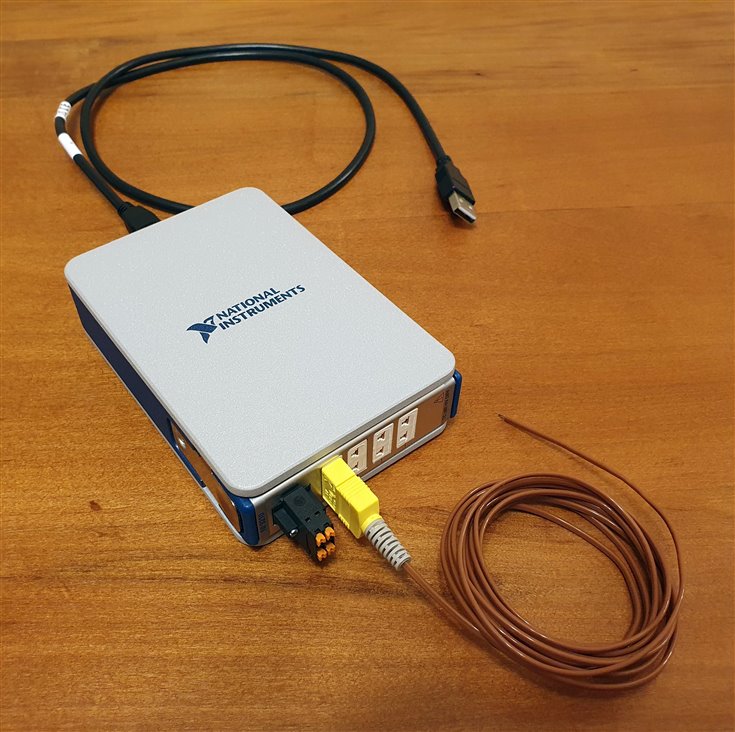

NI CompactDAQ 9171

cDAQs systems control timing, synchronization, triggering and data transfer between modules and the host. These systems are rugged, constructed from A380 cast aluminum and can withstand operating temperatures from -20 °C to 55 °C and up to 30 g of shock.

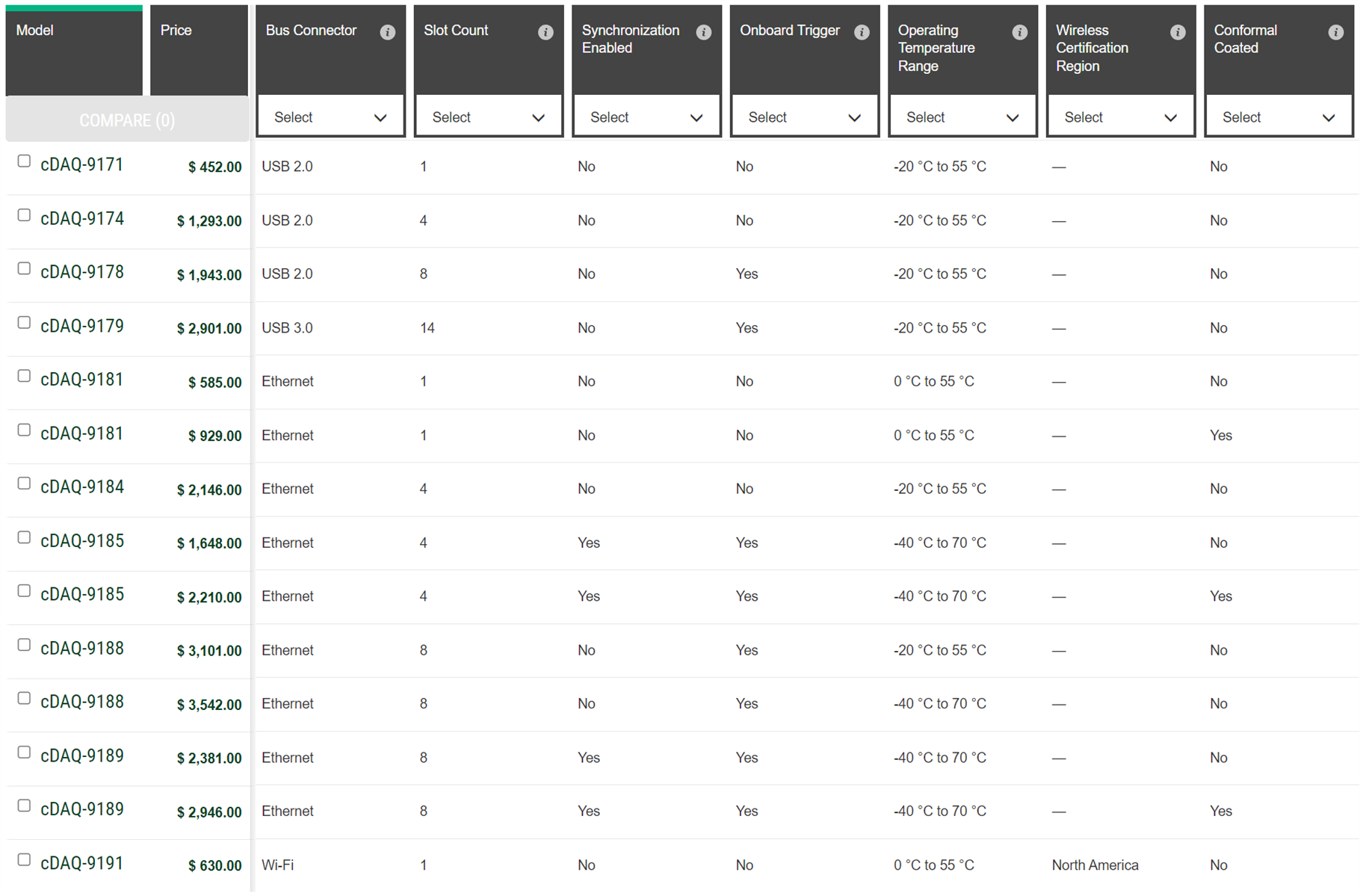

cDAQs come in multiple slot counts, ranging from 1 to 14 slot chassis. Within the inexpensive single slot chassis category NI produces 4 different ones that differ in their connectivity (USB, Ethernet or WIFI), the addition of conformal coating to protect the chassis from moisture and the operating temperature. Of these 4 cDAQ chassis the cDAQ-9171 is the least expensive one and is based on USB 2.0 and has no conformal coating.

The cDAQ-9171 comes with a locking USB cable that can be attached to the chassis with jackscrew. It also has two keyholes for mounting it to a panel or wall with two screws. Two LEDs indicate the status of the device. The ACTIVE LED lights green when there is USB traffic and turns off when there is none. The READY LED indicates the status of the USB connection. Before a USB connection is established the LED stays off, after a connection is established, it lights green if it made a full-speed (12 Mb/s) connection or amber if it made at hi-speed (480 Mb/s) connection. A grounding screw is available to ground the device and enhance the electromagnetic compatibility (EMC) performance of the device.

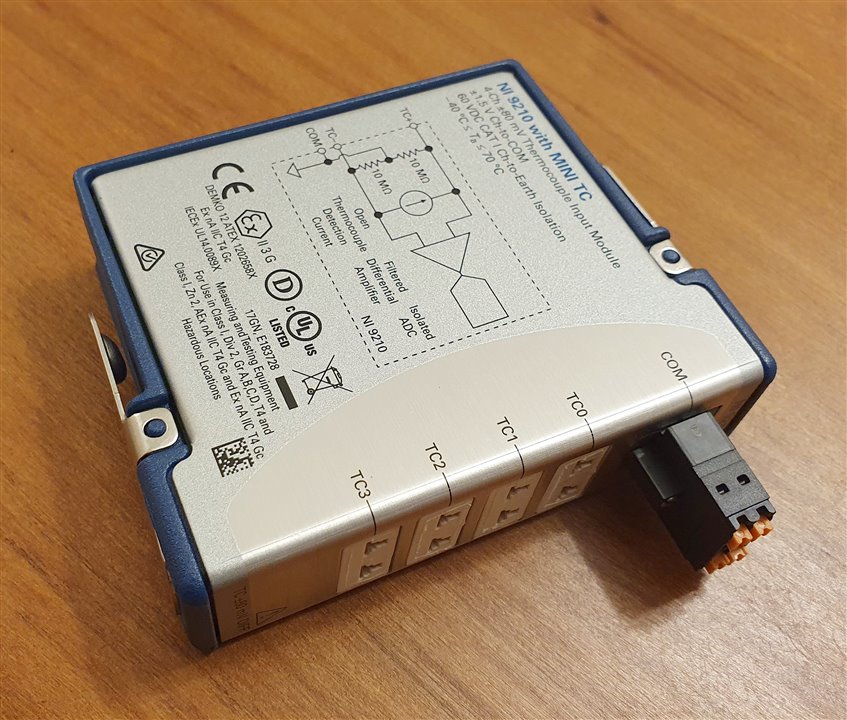

Temperature Module NI 9210

The NI-9210 is a 4-channel 14 S/s, ±80 mV thermocouple module with 50 Hz / 60 Hz noise rejection and 60 V DC channel-to-earth isolation. It includes anti-aliasing filters, open-thermocouple detection, cold-junction compensation, and supports J, K, T, E, N, B, R, S thermocouple types.

The NI-9210 comes in two version, with mini-TC and screw terminal connectors but this is not the only thermocouple cDAQ module made by NI as it can be seen in the table.

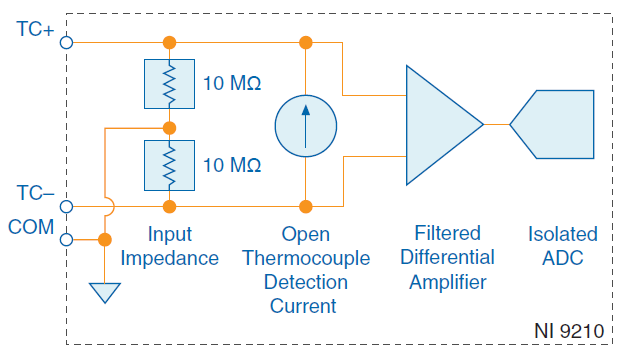

The block diagram of the Module is as follows:

The module supports channel-to-earth isolation (60 V DC Cat I), but not channel-to-channel isolation. A common terminal is provided to use with shielded thermocouple leads (as in some cases the leads can pick up noise). 10 Megaohm resistors are used to keep the voltages of the thermocouple leads within the range of the differential amplifier, while at the same time minimally affecting the voltage generated by the thermocouple. A current source between the thermocouple leads generates a full-scale voltage if the thermocouple breaks (opens), or if no thermocouple is connected.

Thermocouples returns voltages that are roughly proportional to the temperature difference between the measurement junction (hot junction) and the reference junction (cold junction), or in other words, return the relative temperature between the measurement and reference junction. To measure the absolute temperature at the measurement junction, a temperature sensor is used at the reference junction. The temperature at the reference junction is measured, translated into its equivalent voltage as if it was referenced to 0 ºC, then the thermocouple voltage and equivalent voltages are added and finally translated to the temperature (of the measurement junction). To increase the accuracy of the measurements even further, the module provides autozeroing functionality that can compensate offset errors.

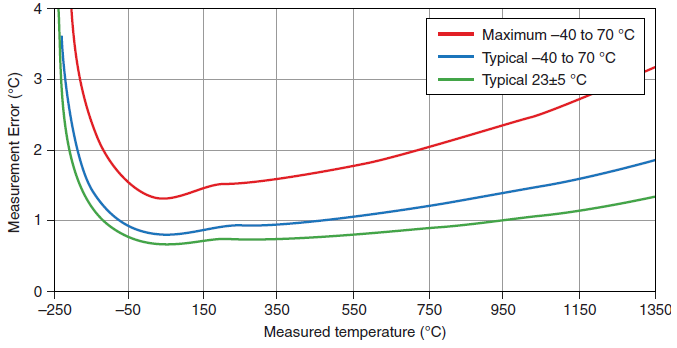

Now, errors could still be introduced if a thermal gradient builds up across terminals, so care must be taken to avoid that. The following table shows what accuracies can be achieved with a K-type thermocouple:

Omega 5SRTC-TT-K-24-72 Thermocouple

The Seebeck effect is the electromotive force (EMF) that develops across two points of an electrically conducting material when there is a temperature difference between them. If a single material wire is heated or cooled in the middle, and both ends of the cable are the same temperature, no voltage will develop across the ends as the Seebeck effect cancels out. But, if two dissimilar conductors forming an electrical junction (measurement junction) get heated (or cooled) at the junction, a temperature-dependent voltage develops because of the Seebeck coefficient difference. The Seebeck coefficient is the voltage per unit of temperature generated as result of the Seebeck effect. The voltage generated is roughly but not completely linear, so within certain range of temperature the coefficient gives a good approximation of the generated voltage per unit of temperature.

Thermocouples are devices made of two dissimilar wires joined at one end (the measuring junction) that produce a temperature-dependent voltage roughly proportional to the temperature gradient.

Different types of thermocouple standards exist such as the J, K, T, E, N, B, R, S. Each of these are made of different materials and their voltage-temperature curve is well defined. The K-type is a popular one, it is inexpensive and made of chromel (an alloy made of 90% nickel and 10% chromium) and alumel (an alloy made of 95% nickel, 2% aluminum, 2% manganese and 1% silicon). The K-type probes are inexpensive have a sensitivity of roughly 41 µV/°C and can be made to support temperature measurements from -200 °C to 1350 °C.

The 5SRTC-TT-K-24-72, manufactured by Omega, is a K-type, 24 AWG (0.51 mm diameter), 2 m long, PFA (max 260 °C) insulated thermocouple. NI included a pack with 5 of these thermocouples.

FlexLogger

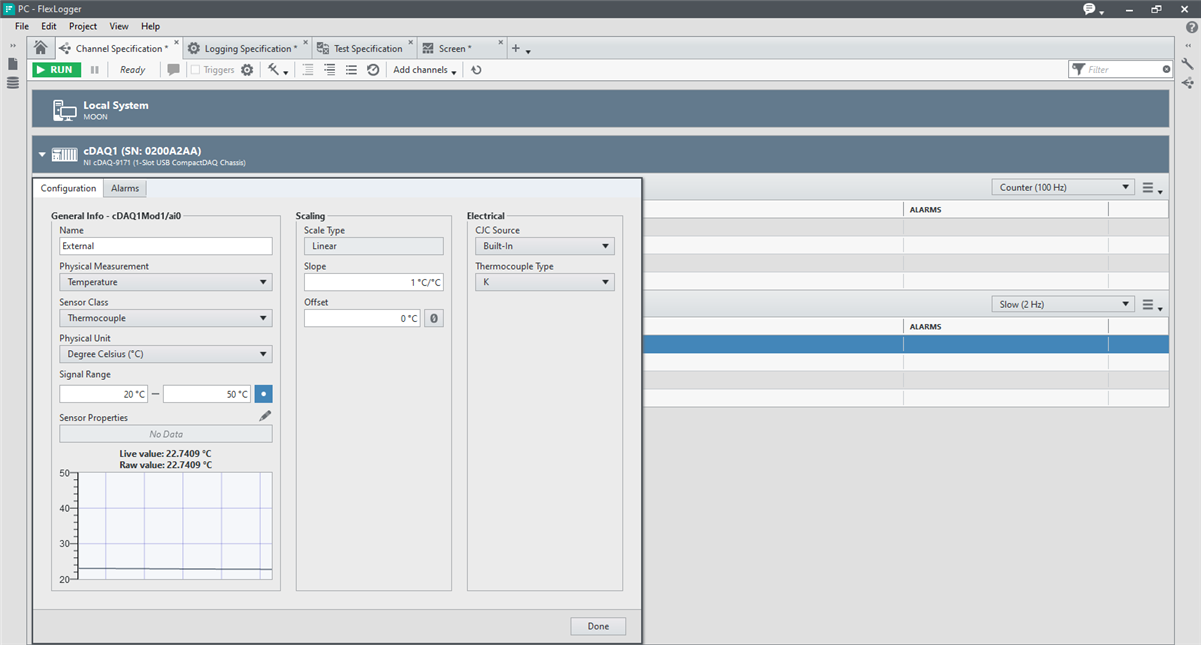

FlexLogger is an application that helps the user to build data-logging systems without any programming. It allows the user to configure NI hardware, build front panels for real-time data visualization, setup warnings and events, and synchronize the data captured.

The FlexLogger package also comes with a TDMS Viewer application that can be used to explore the captured data. It supports exploration of the data and metadata, plotting, and math operations on the data such as algebraic operations, filtering and FFT.

A more detailed description and demonstration on how to use FlexLogger to measure the computer case inner air temperature will be given later.

Experiments

NI Thermocouple Kit: PC Temperature Measurement with FlexLogger

I installed 3 thermocouples at different locations inside of a desktop computer case to measure the air temperature as the computer performed different tasks. FlexLogger was used to do the data-logging and FlexLogger TDMS Viewer to process and visualize the logged data.

Follow this link to read more.

NI Thermocouple Kit: Temperature Control with LabVIEW

I built a temperature control system with LabVIEW that used the cDAQ, an SMU and a Peltier device to control the temperature of beaker filled with mineral oil. I show how LabVIEW works and how it can be easily interfaced to the cDAQ using NI-DAQmx nodes, and to the SMU using VISA nodes.

Follow this link to read more.

NI Thermocouple Kit: Fan Heater Temperature Measurement with Python

I measured the temperature of a fan heater at different distances from the exhaust using Python's NI-DAQmx library. Here I show that controlling the cDAQ from Python and LabVIEW is not really that different.

Follow this link to read more.

NI Thermocouple Kit: Thermal Capacity and Rate of Heat Loss Estimation

I used an SMU to inject heat into a thermal system and the cDAQ with Flexlogger to record the ambient and the thermal system temperature. With the recorded data I built a simple thermal model which I fitted to the empirical data to estimate the thermal properties of the system.

Follow this link to read more.

Conclusions

Having previously worked with NI DAQs I must admit that it did not surprise me that it worked as expected and as it should. NI DAQs that rely on NI-DAQmx are essentially all controlled in the same way, and this makes porting of programs very easy as on many situations no changes need to be made to support different hardware.

FlexLogger on the other side was an application which I had no experience with. To make measurements I would usually use LabVIEW or Python. And as I showed in some experiments, making measurements in either of the two environments requires very little effort. So, before testing FlexLogger I was not sure what it could offer that would make it attractive for data-logging. After testing it I found that it does fill a few spots not filled by the other environments. If the only thing that needs to be done is to capture data, display it on a simple panel and log everything into a file, FlexLogger is probably the best alternative. Compared to LabVIEW it will take less effort to configure the hardware and log the data, as FlexLogger does not require programming. Compared to Python, designing a front panel in FlexLogger requires far less effort than with Python. On the other hand, if the data needs to be processed during the capture or if non-trivial logic needs to be executed during the capture, FlexLogger will not be able to do that. This is expected though, as the NI advertises FlexLogger as a non-programming application targeted at data-logging.