RoadTest: Cool Tools - Molex Hand Crimper

Author: s1m0n3t

Creation date:

Evaluation Type: Connectors & Cable

Did you receive all parts the manufacturer stated would be included in the package?: True

What other parts do you consider comparable to this product?: I think there are no comparable tools, fully compatible with Molex Pico-Clasp terminals

What were the biggest problems encountered?: I have not encountered any particular problems. Despite this it should be noted that with this type of contacts, of very small size, patience is needed to insert each contact in the correct position.

Detailed Review:

Do you need small but reliable connectors for your project or product? Maybe you can consider the Molex Pico-Clasp series.

They are 1.00mm-pitch wire-to-board connector, ranges from 2 to 50 pin, available with vertical and right angle male PCB headers and female cable connectors.

These are the main features of this connectors family:

Pitch: 1.00mm

Circuits: 2 - 50

Max. Derating Current: 2.0A

Max. Voltage: 100V AC (RMS)/DC

Wire size (for crimp terminals): AWG28 to AWG32

If you want to learn more about these connectors you can find more details and products specifications, you can check the manufacturer website:

https://www.molex.com/molex/products/family/picoclasp

The one thing you should take into consideration if you are using such a compact connector is that you will definetely need a crimping tool that is up to the task!

In my review I will try to crimp these terminals manually, with common pliers (and a lot of patience!) and compare the result using the Molex Crimp Tool.

What I received

I received the 638191500 crimp tool, few 5013340000 terminals (28-32 AWG, Tin Plating) and few meters of AWG28 wire.

I separately ordered few Pico-Clasp connector housing samples and I used also AWG32 wire to complete the test.

Tool overview

At the first approach with this tool, the solidity and construction quality are evident.

In detail we can observe the tooling die and the locator from the back.

Crimp procedure

Let's test this tool! In the following video you can see in details how to crimp Pico-Clasp terminals with this tool, in 5 easy steps:

Link to the video: https://youtu.be/zgmi8v7Gbd8

Trying to crimp manually...

Let's say you want to use these connectors in your small project. Or, for example, you have an existing board with this connector and you want to crimp a single cable with a mating connector. You don't want to spend a lot of money to buy a professional crimp tool, of course! Can you do it manually, only with the help of pliers and tweezers (and maybe a magnifying glass)?

So...my answer is YES, you can!

Is it worth it? Definitely no.

Can you get a good result? Hardly...

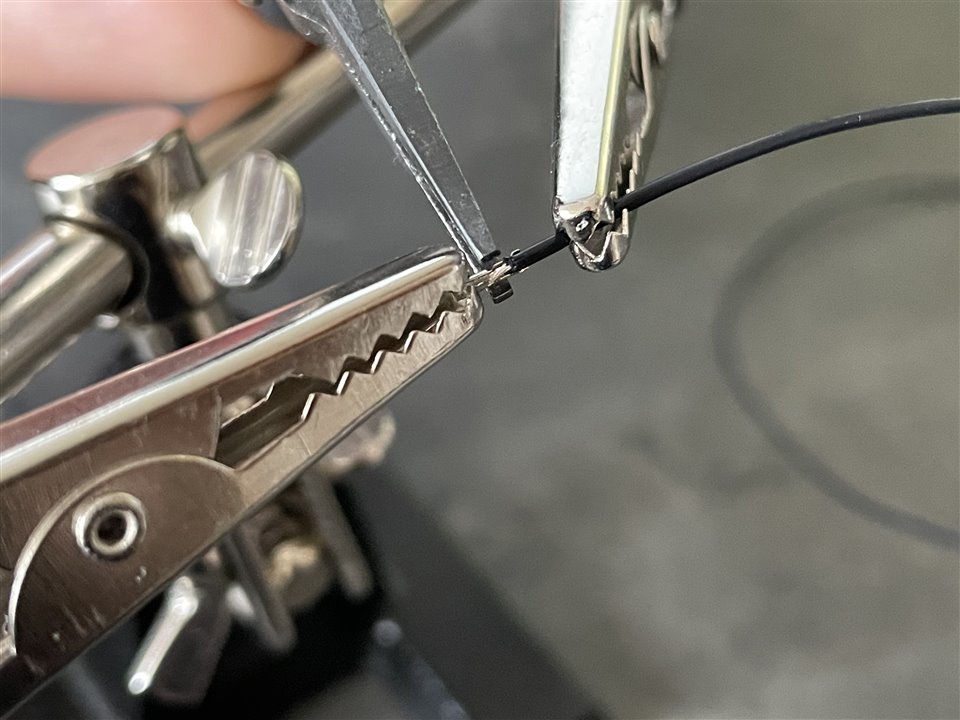

I used a third hand to hold the terminal and the wire in position while I used pliers to crimp.

This was successful, but the risk to damage the tiny terminal spring is too high. I needed few minutes to perform the crimp of only one terminal.

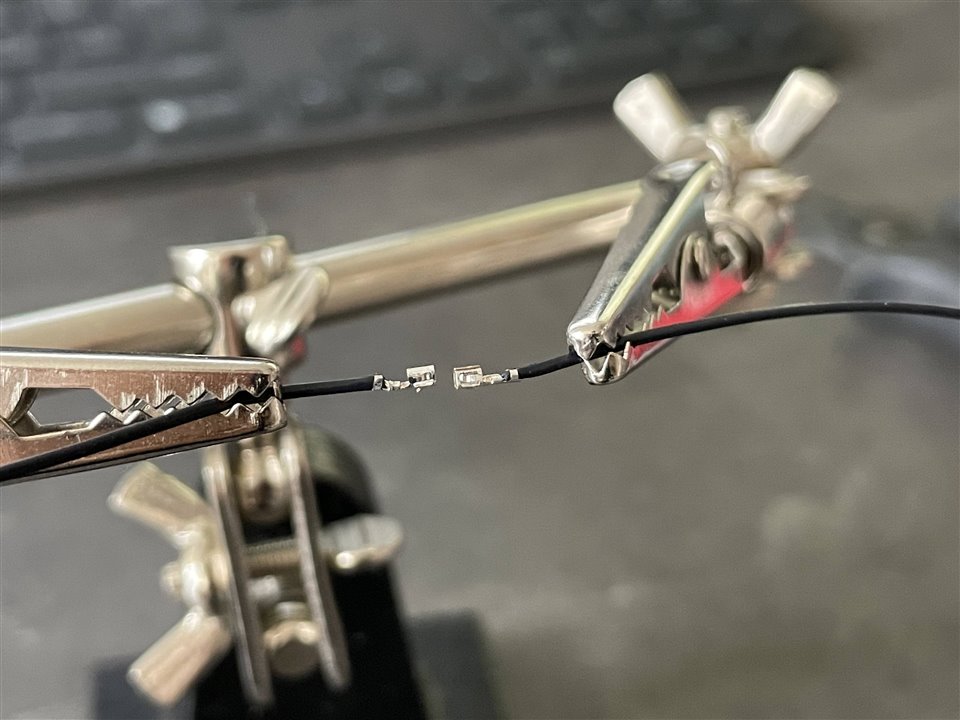

Let's look at the results (next image)... It's not difficult to guess which is the manual crimped terminal and the tool crimped one (spoiler: on the right, of course!).

Testing the crimping pull-out force

A good metric for evaluating the performance of a crimping tool is the maximum pull force that the cable/terminal pair resists before coming off.

To perform this test, even if it's not a professional way to do that, I clamped the terminal to a small vice, and gently pulled the cable through a luggage scale. Then I recorded a video of the display to get the max value, equal to the force necessary to tear the contact from the cable. The value is a weight, expressed in kg, but it's easy to convert it into a force, expressed in N, multiplying the value by 9.8.

You can find the expected pull-out force on the table 6.2 (Mechanical performance) of the Pico-Clasp Product Specification document (https://www.molex.com/pdm_docs/ps/5013301000-PS-001.pdf)

Test setup

Detail of the terminal tight in the vice:

Here you can find the recorded videos for each test:

Link to the video: https://youtu.be/_GYWGWGIshQ

Test results

Here you can find the measured pull-out force, tested with AWG28 and AWG32 wires, crimped with the tool and manually, compared with the requirements on the datasheet:

| Wire gauge | Requirement | Measured (tool crimped terminal) | Measured (manual crimped terminal) |

| AWG28 | 9.8 N (1.0 kgf) | 17.8 N (1.82 kgf) | 5.6 N (0.57 kgf) |

| AWG30 | 4.9 N (0.5 kgf) | N.D. | N.D. |

| AWG32 | 3.0 N (0.3 kgf) | 7.8 N (0.80 kgf) | 4.70 N (0.48 kgf) |

As expected, the measured pull-out force exceeded the requirement, but the value for the manual crimped terminal is worse (did any of you expect the opposite?).

Conclusions

This RoadTest allowed me to thoroughly test this tool and crimping techniques. And it will allows me to easily use these cool connectors in my future projects.

Lesson learned: you can crimp by yourself some connectors using common tools, even the smaller one, but you can't expect a good result and an affordable connection.

Thanks to element14 and Molex for making this possible!