RoadTest: Flusso FLS110 Mass Flow Sensor Evaluation Kit

Author: robertoquintal

Creation date:

Evaluation Type: Evaluation Boards

Did you receive all parts the manufacturer stated would be included in the package?: True

What other parts do you consider comparable to this product?: MPX5010DP

What were the biggest problems encountered?: Calibration

Detailed Review:

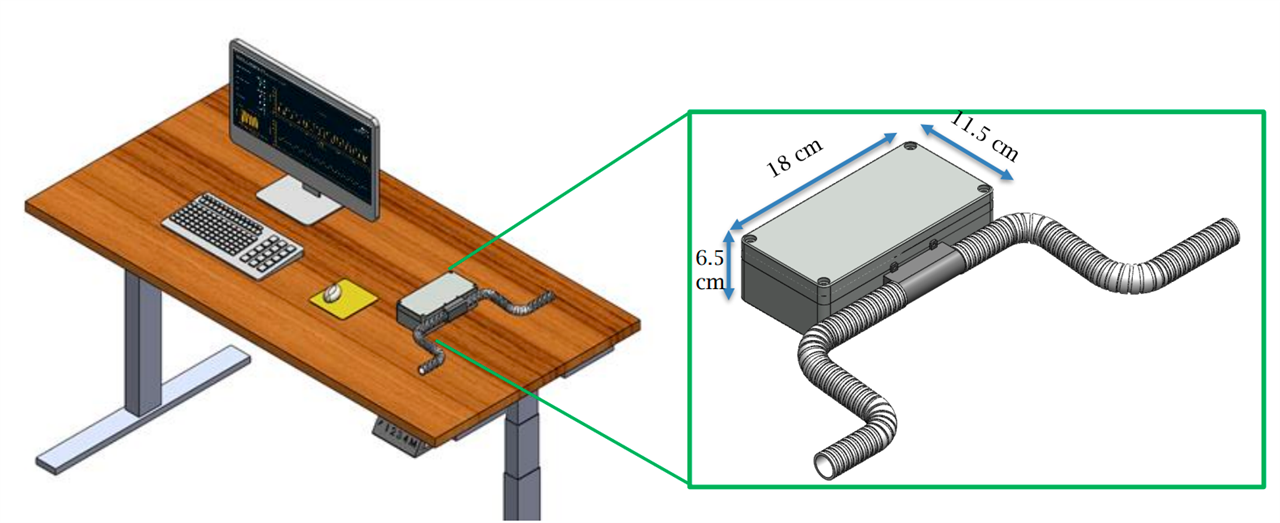

The PVME (Proyecto Ventilador Mecánico para Emergencias) is a self-made pneumotachograph based on a RPi4 with a GUI, calibrated for air flow measurements, intended for medical purposes (see Figure 1 and 2).

Fig. 1 Design of the pneumotachograph made at Universidad Autonoma de Yucatan

Fig. 2 The pneumotachograph built with the GUI on screen

The pneumotachograph works under the Venturi effect (see Figure 3) by measuring the difference in pressure at two points with a differential pressure sensor (MPX5010DP).

Fig. 3 Venturi effect with pressure plot over flow trajectories

The PVME calibration parameters were adjusted to achieve precision and repeatability in the measurements based on the standard syringe used for medical equipment calibration as shown in the following video.

Due to the hose diameter of the medical equipment, a venturi tube had to be 3D printed in order to fit the Flusso FLS-110-EK-1174, its should be acknowledge that the manufacturer can also provide such accessories for an extra cost. The printed venturi tube is shown in Figures 4, 5 and 6.

Fig. 4 3D printed venturi tube for the Flusso sensor with dimensions

Fig. 5 Section view of the 3D printed venturi tube for the Flusso sensor

Fig. 6 Printed venturi tube with filter

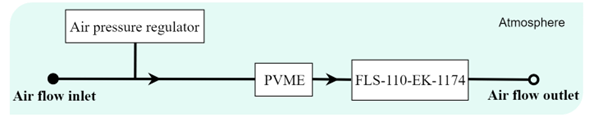

A controlled experiment was conducted for calibrating the FLS-110-EK-1174. The diagram of the experimental setup is shown in Figure 7 and Figure 8.

Fig. 7 Calibration setup diagram

Fig. 8 Calibration setup

Compressed air is supplied to the system and regulated via a Festo industrial air pressure regulator and maintained at a constant value. Air goes through the PVME pneumotachograph which is used as a reference to measure the constant volume flow through the system as a function of the inlet air pressure. Air then passes through the FLS-110 for calibration via the FLUSSO GUI. Air ends its path at ambient pressure. The PVME pneumotachograph and the FLS-110 are connected in series.

Regarding the GUI calibration, the following points were considered.

• The Zero -point offset has been determined in ambient conditions, with no flow through the system.

• The Flow temperature (Tflow) offset has been approximated as the ambient temperature, which remained approximately constant at 25°C.

• The Three-point system calibration option was used for calibration, in which the coefficients (C1, C2 & C3) were determined on the Vol. flow/DP basis in LPM units. This process was performed two times with varying setpoints.

The resulting coefficients for each calibration are shown in the table below.

Table I Calibration coefficients for different setpoint values

| Setpoints | Coefficient | Value |

| S1 = 1.0 | C1 | 146.13 |

| S2 = 1.5 | C2 | -4961.75 |

| S3 = 2.0 | C3 | 131704.50 |

| S1 = 0.5 | C1 | 197.4727 |

| S2 = 1.25 | C2 | -11641.2588 |

| S3 = 2.0 | C3 | 333776.6875 |

After the calibration was done for the second group of setpoints, the following measurements were taken as shown in Figure 9.

Fig. 9 Measurement comparison between PVME and FLUSSO systems, taken at the different setpoint values shown in Table 1 according to the coefficients for S1 = 0.5, S2 = 1.25 and S3 = 2.0

These measurements were performed at a constant inlet air pressure in the range of 0 – 10 psi which derived in the approximately constant air flow measurements in LPM shown in Figure 9, the time of each measurement was taken arbitrarily. The measurements in pantone blue and gold are for the PVME and FLUSSO sensors, respectively.

In Figure 10 the Flusso's GUI is shown

Fig. 10 Flusso's GUI

The medical equipment (pneumotachograph) usually is calibrated with a syringe of a known volume, so that it in practice it shows the total volume exhaled or inhaled by the patient. The precise value of the air flow is not of importance in terms of medical diagnosis, as the total volume in and out of the patient is the variable to really consider.

In Figure 11 the flow of the 3 liter syringe is shown for both sensors. Notice that the integration of the signal should be 3 liters ± 3%.

Fig. 11 Comparison between sensors for calibrated 3 liter precision syringe.

Finally the video of the precision calibration is shown.