RoadTest: Sign Up to Review the Aim-TTi Source Measure Unit SMU4201

Author: jwr50

Creation date:

Evaluation Type: Test Equipment

Did you receive all parts the manufacturer stated would be included in the package?: True

What other parts do you consider comparable to this product?: Keysight B2900B/BL, Keithley 2400

What were the biggest problems encountered?: I had to find a set of probes that worked for the front end interface. However, the rear panel interface may prove more useful going forward.

Detailed Review:

This RoadTest Review looks at the Aim-TTi SMU4201 source measurement unit (SMU). The Aim-TTi SMU4201 is a capable and easy-to-use SMU with advanced features that makes it a good addition to a professional workbench. I will take an Aim-TTi SMU4201 through its paces, starting with basic measurements and building up to more advanced features. The Test Procedure I am following is attached below.

A source measurement unit or "SMU" allows simultaneous measurement of current and voltage while acting as either a source or sink. The main purpose of a SMU is to measure the current vs voltage (I-V) curves of linear and nonlinear electrical components, but can also act as a precision power supply and digital multimeter.

A SMU is usually referred to as a “four quadrant” measurement device, meaning that an SMU can be either a source or sink for current or voltage. And since a SMU can operate as a current source or sink, the SMU can even characterize energy storage devices like batteries and solar panels. Basically, a SMU can determine the current and voltage relationship of most common devices. If there are more that two terminals, i.e. a transistor such as a Power FET, two SMUs can be combined to perform the I-V characterization.

Component characterization: An obvious SMU application is component characterization. Engineers and technicians can spot-check components during troubleshooting. Manufacturers as well as quality control engineers can instantly check components such as diodes (or transistors with two SMUs) against specifications or to generate datasheets. Automated testing can be used to compile statistics and place error bars on component values.

Battery voltage vs time: Battery powered microcontrollers, measurement and IoT devices need to consider the implications of limited available power. An important consideration is battery technology. An SMU can help answer the following questions: Is a LiPo batteries required for my application? Or can my project get away with alkaline or even coin cell batteries. What about low power or brownout conditions? Does the battery voltage fall quickly or gradually? How much time does the MCU and peripherals have to safely power down? What is the voltage range during normal operation? Does the voltage drop overtime or under load and how much?

Optimizing MCU power consumption: Microcontroller power consumption optimization balances system features with the available power source. In general, this will involve a number of engineering tradeoffs including cost, size, thermal, and performance. But for a given battery source, a SMU can measure power consumption rates of given microcontroller configurations and allow reasoned choices to be made when disabling features, choosing clocking strategies, RF radio communication strategies, etc.

Off-grid power circuitry: A SMU can measure charge and discharge rates for solar powered battery systems. Again, this allows decisions to be made for a given solar panel system capacity.

Unboxing

The SMU4201 box contains the Aim-TTi 4201 instrument configured for 115V for the US market and the appropriate NEMA 5-15 to C13 instrumentation power cord, as shown in Figure 1. While not included with the SMU4201, I will be using two pairs of banana cables with alligator clips connected to the front panel. Figure 2 shows additional ports are on the rear panel that can connect the device under test with standard wire connections. A USB port, LAN port and GPIO are provided for remote operation and automation. These devices are described in the provided Quickstart Guide and online. I will use the USB connection to demonstrate programming features in the Automation and Programming section.

Figure 1. SMU4201 front panel and included cables.

Figure 2. SMU4201 back panel.

The SMU4201 has a number of presets for common SMU operations available through the “Easy Setup” menu. Figure 3 show the top-level configuration menu with "Easy Setup" and "Manual Setup" measurement actions. The following “Easy Setup” features will be demonstrated with a power resistor as our device under test (DUT) because it is passive and linear and can effectively demonstrate the SMU capabilities.

Figure 3. Main configuration screen, including "Easy Setup" and "Manual Setup" modes.

The most basic operation of an SMU is a power supply capable of supplying a constant current or voltage. The first step is to demonstrate the power supply capabilities of the SMU4201 into our resistor DUT.

Figure 4. Easy Setup - Power supply into resistive load.

Precise voltage and current measurements can be performed in a device when an external DC power supply is driving the DUT.

Figure 7. Easy Setup - Ammeter configuration.

The SMU can be a very accurate Ohmmeter. In order to create a 4-terminal resistance measurement

Figure 8. Easy Setup - Ohmmeter resistor measurement.

The SMU4201 can generate characteristic I-V curves for non-linear devices such as diodes, FETs, batteries, ICs, etc. The SMU4201 will need to be set manually with the Manual Setup configuration menu

Diodes such as switching diodes and LEDs have a characteristic I-V curve such that current is near zero for negative voltage bias, but rises exponentially for positive bias. From the I-V curve of a given diode, the maximum operating current, and reverse loss current can be determined.

Figure 9. Manual Setup - Switching Diode I-V curve.

A Zener diode is similar to the previous diode, except the diode will conduct for sufficiently negative voltages.

Generate I-V curve and save screenshot

Figure 10. Manual Setup - Zener Diode I-V curve.

In previous measurements of passive components, the SMU4201 was configured as a current or voltage source (also known as quadrant I and III). Battery discharge can be characterized by configuring the SMU4201 as a current sink to simulate a device with a constant current draw. This example uses a CR2032 coin cell with a 50 mA sink current and a 1V dropout. The voltage in Figure 11 starts around 1.6 V and drops down to the programmed 1V.

Figure 11. Manual Setup - Battery discharge curve.

The Test Bridge software supports the Aim-TTi SMU4201 in the Windows environment, and appears to be a good application for automating SMU tests. I took a different approach in this RoadTest and explored programming the SMU4201 at a lower level with entirely open sourced tools.

The SMU4201 supports control and automation through Standard Commands for Programmable Instruments (SCPI). SCPI allows flexible data acquisition, collection and analysis of measurements. The commands are encoded strings and measurement setups consist of multiple commands sent in successions. The list of available SCPI commands are listed in the Aim-TTI 4200 Series Programming Manual.

SCPI Programming With Python

A very straight-forward method of sending SMU4201 SCPI commands is to use the USB interface and Python. These are simple examples, but suggest how more complex automated test setups and frameworks can be created using open source tools. For this example, I used Ubuntu 22.04.2 LTS and Python 3.10.6, though this should work for a wide variety of Linux systems and Python3 versions.

Setup

Make sure the user is in the dialout group:

jerahmie@minion:~$ groups

jerahmie adm dialout cdrom sudo dip plugdev lpadmin sambashare lxd docker

If the user is not in the dialout group, add it with:

# usermod -a -G dialout <username>

Logout, log back in and check that the user is in the dialout group.

Attach the Aim-TTI SM4201 to an open USB port and ensure it is enumerated on the host system.

$ lsusb

…

Bus 001 Device 003: ID 103e:04f6 THURLBY THANDAR SMU4201

…

Obtain the serial device port with the following command. The serial device of interest will have the form of /dev/ttyACM* or /dev/ttyUSB*.

$ ls /dev/tty*

…

/dev/ttyACM0

…

Install pyserial either onto the system or in a virtual environment:

$ apt-get install python3 python3-pip

$ pip3 install pyserial

If everything works, the following commands should return the SMU4201 identification string.

$ python3

>>> import serial

>>> conn = serial.Serial(port=’/dev/ttyACM0’, baudrate=115200)

>>> conn.write(‘*IDN?\n’.encode)

>>> print(conn.readline())

b'THURLBY THANDAR,SMU4201,576126,1.4.1-1.1-1.6-1.2-1.0\r\n'

Example: Voltage Measurement

An example 3V DC with a primary current measurement and secondary voltage measurement is set with the following Python command:

cmd = 'SYSTem:FUNCtion:MODE SOURCEVOLTage;' + \

':SOURce:VOLTage:CURRent:LIMit 0.04 A;' + \

':SOURce:VOLTage:MEASure:PRIMary CURRent;'+ \

':SOURce:VOLTage:MEASure:SECondary VOLTage;' + \

':SOURce:VOLTage:SHAPe FIXed;' + \

':SOURce:VOLTage:FIXed:APERture:TIME 1S;' + \

':SOURce:VOLTage:FIXed:LEVel 3.0\n'

conn.write(cmd.encode())

The following command is equivalent to pressing the ‘Run’ button.

conn.write(‘OUTPut:STATe 1\n')

And the results are read and printed with the following commands:

conn.write('MEMory:DATA:BUFFer:ASCii?\n'.encode())

print(conn.readline().decode())

A Python program that issues the above command is available in my github repo:

https://github.com/jerahmie/ttismu4201

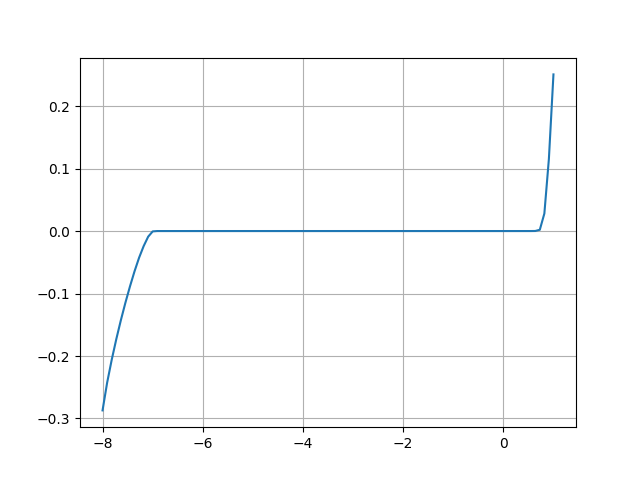

Example: Automated Zener Diode Voltage Sweep

By using Python for issuing SCPI commands, third party modules can be used to analyze, export and plot measurement data. The sweep_diode.py example sets up a voltage sweep for a zener diode and plots the results using matplotlib, as shown in Figure 12.

Figure 12. Automated Zener Diode I-V curve captured using Python and plotted with Matplotlib.

In this RoadTest Review, I found that the Aim-TTi SMU4201 is an easy to use yet powerful source measurement unit. This was my first experience using a SMU and found that the touch screen navigation was simple and intuitive. Basic functionality like a power supply and DMM features are available through an "Easy Setup" menu, while more advanced features such as I-V characterization and power sink features are available in the "Manual Setup" menu. I appreciate the use of industry standard SCPI to provide advanced programming and remote operations, which opens a wide variety of options for customization and automation. The Aim-TTi SMU4201 makes a good addition to a professional workbench.