I've been known to throw a circuit together, apply power to it, and fry something. Or the circuit just doesn't work and the problem could be anywhere in that mess of wiring. But I used to work on complex and potentially hazardous projects where we couldn't afford those types of mistakes. There were mechanical, electrical, civil, chemical processing, and instrumentation disciplines, and towards the middle of the design specialists in commissioning and start-up were brought in.

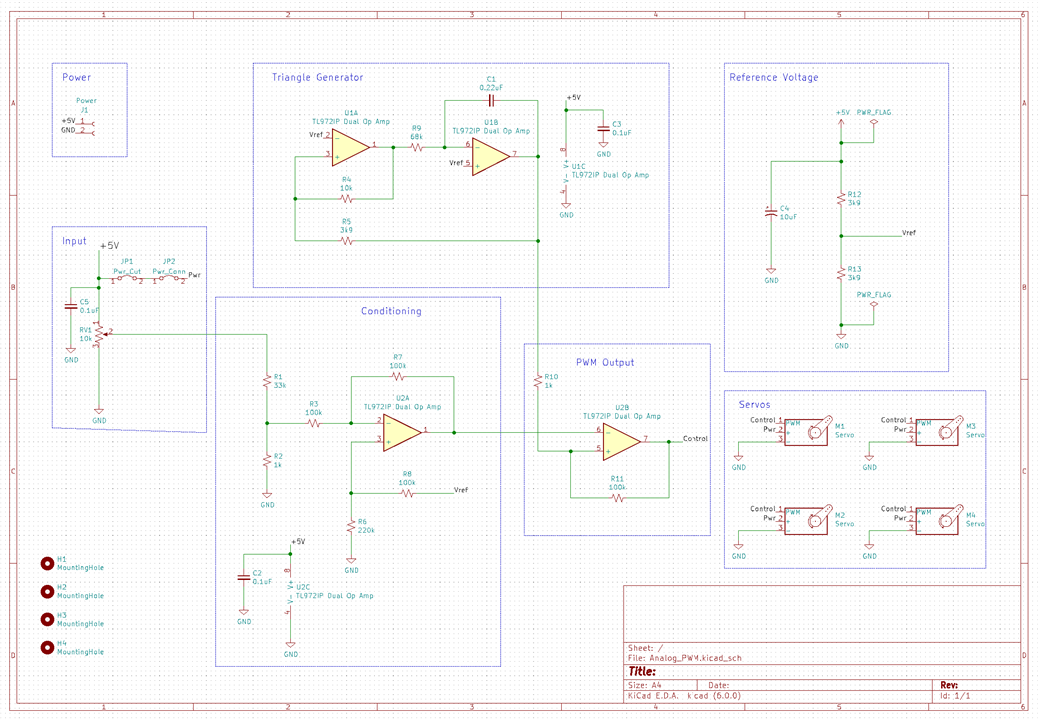

I recently sent out a PCB design for manufacture without prototyping it first. The schematic is shown below but it is just an example. My question is more general to starting up any untested circuits.

Time for me to get my act together. I put together a plan with the following approach:

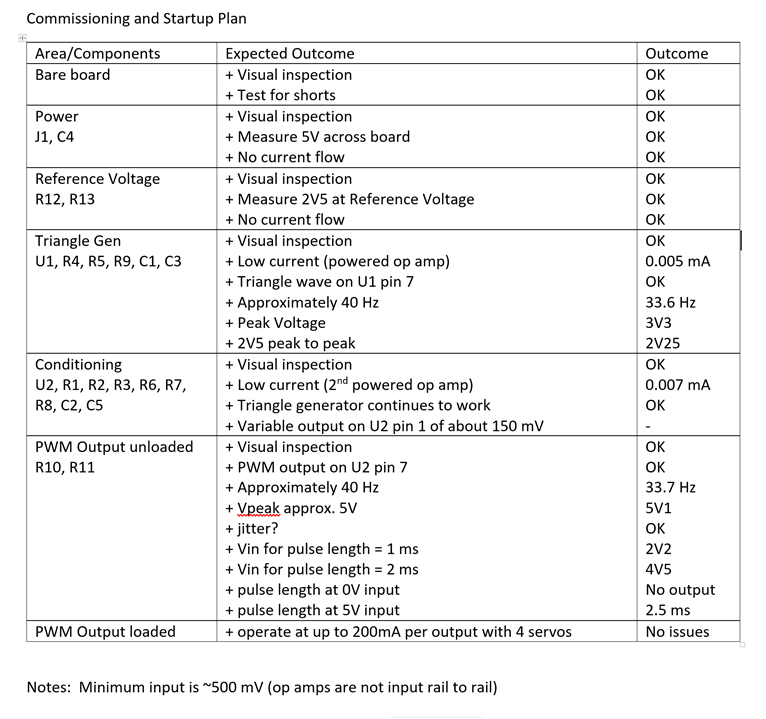

- Break the circuit into logical sections that can be tested sequentially

- Describe the test plan for each section with the expected outcome

- Solder it up a section at a time and test the section before moving on

The actual plan used is shown below.

One lesson from this was that the test plan should have been made before the PCB was sent out which would have allowed for dedicated test points. Not shown in the plan (but they should have been) are the bench power over-voltage and over-current settings.

Fortunately, this board went together and started up without a problem but it got me thinking. What did I leave out? What tips do you have for planning and starting up an untested circuit? Do you know of any good resources on the web?