The cost of prototype flex PCBs seems to have come down a _lot_ with some (not all) prototype PCB manufacturers.

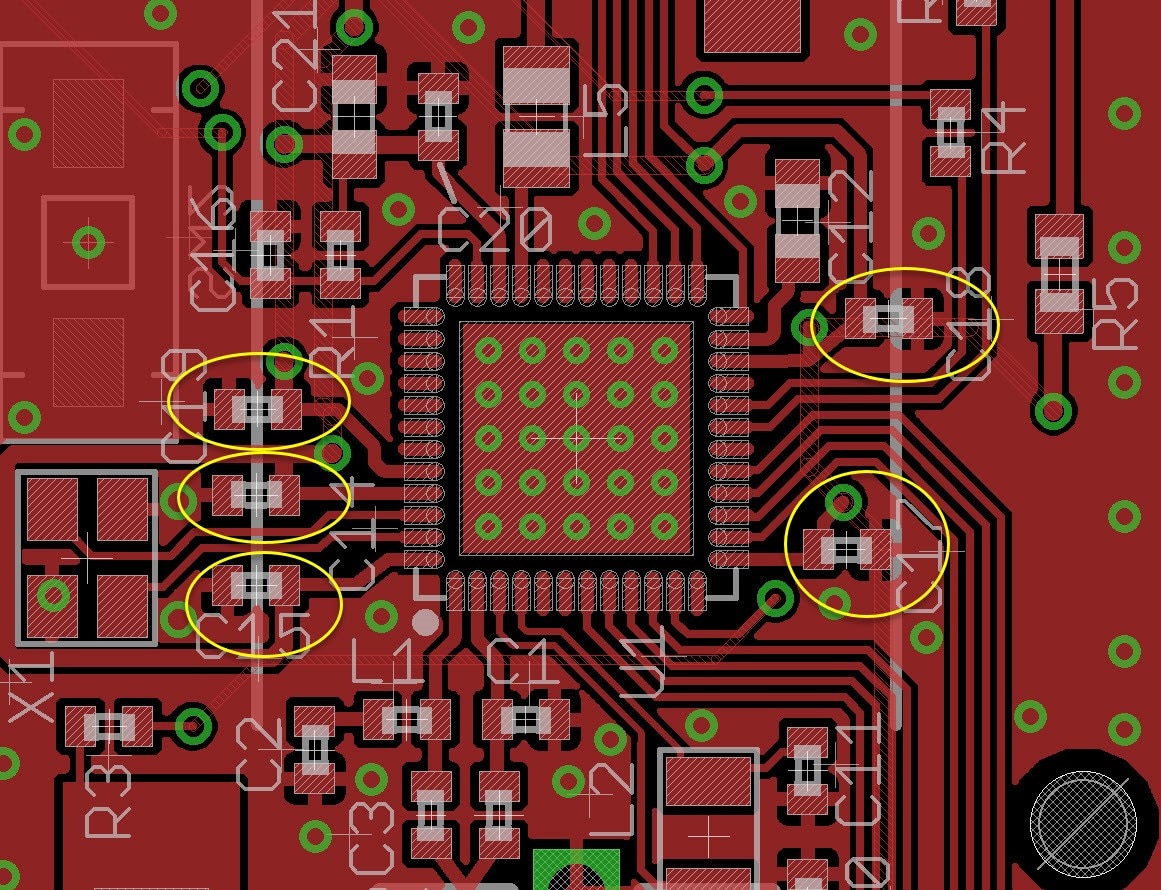

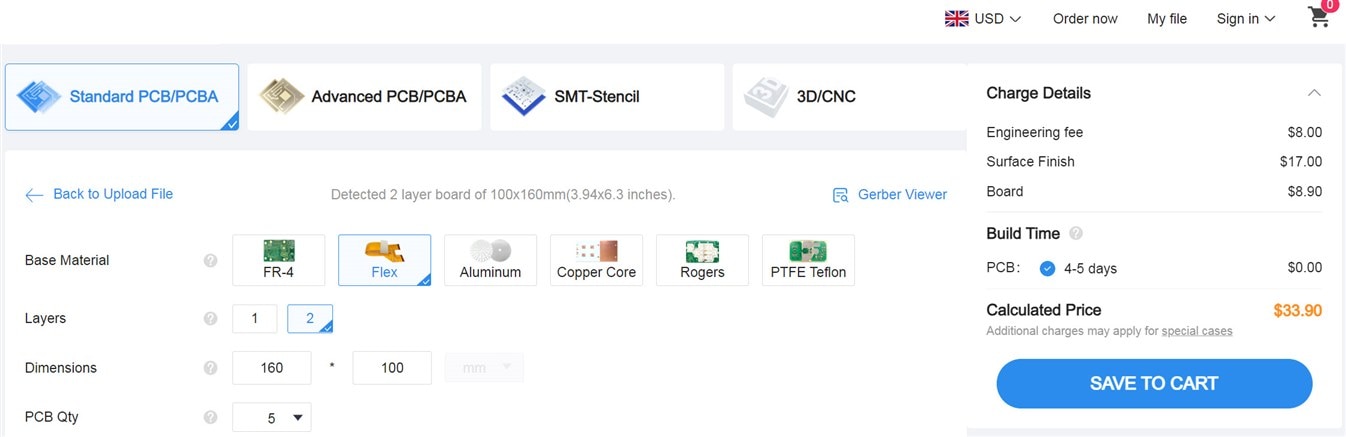

Here's an example quote from a popular (3-letter name) prototype PCB manufacturer, for a 2-layer 160x100mm board with a lot of holes (I randomly chose Gerber files for a normal FR4 project, to generate this quote for now), and ENIG finish by default. $33 for 5 boards, so $6.60 per board basically,. This might actually be cheaper than an FR4 ENIG board!

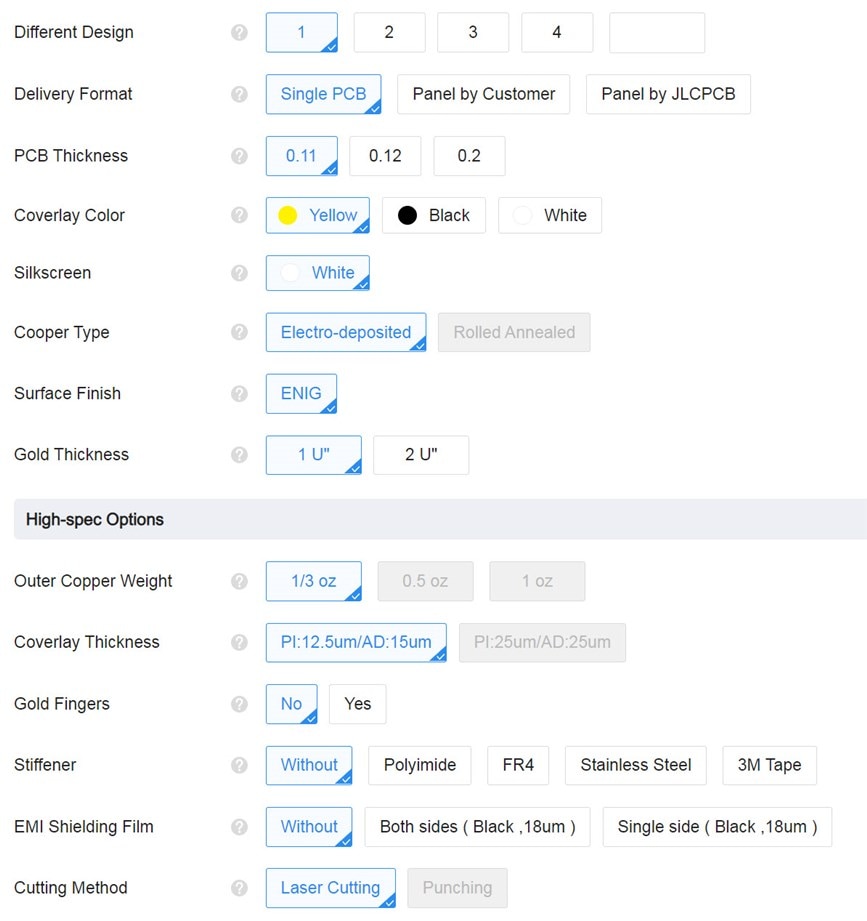

These are the options (default settings); the board thickness is 0.11mm:

Another popular PCB manufacturer (one that is famous for a lot of spam) is currently quoting $158 for five boards of similar size, so that's quite a difference!

I had a variety of general questions since I've never done a flex PCB design.

Could these be useful for perhaps creating membrane-style keyboards? I'm thinking that perhaps the solder mask might be thick enough to create separation between the flex PCB and (say) an FR4 base, to create a PCB maybe. Alternatively, a laser-cut sheet could be placed in between for added separation. Has anyone tried such a thing? I'm considering it for a keypad with many dozens of keys for a variant of this project: Triggered Sound FX: On-the-Fly Sound Mixing with Pi Pico

Are there any tips/tricks for flex PCBs? For instance, are there particular components or connectors that lend themselves to such use, and are some components best avoided? Any checklist you use for flex PCB designs?

Would you rarely apply components to a flex PCB (using it as an interconnect), or are you comfortable with components on them? Both sides or one side? : )

Has anyone tried soldering flex PCB directly to a FR4 PCB? I have done this with the flex on some LCD displays, and it is great; they have tiny holes for allowing the flux or excess solder to pop out of, and it works very well. I was wondering if the prototype flex PCB would behave the same as the flex on typical LCD screens.

Any problems with warpage, etc., i.e., if the flex PCB outline is intricate, will it curl up while it is being manufactured, potentially getting damaged?

Are any particular copper features or trace thicknesses best avoided for portions of flex that may be bent a lot (or even repeatedly)?

What applications do you have for flex PCBs? Are you considering them for any prototype or product, perhaps where you would typically not consider them, now that they are lower cost?

I apologize for all the questions, but I figure someone must ask the basic questions!

All comments are welcome! (apart from spam!).