Introduction

In an earlier blog post Very Low-Cost Pulse-Width Modulation (PWM), and Isolated Analog Measurements a method was discussed to perform isolated analog measurements at a sub-£1/$1 price. It was fine for slow-changing signals, but I wanted something that could be used at up to say 100 kHz too.

This blog post discusses the work done so far. Note: it is not a functioning project, it is still a work-in-progress, with some known faults, and probably some unknown ones too. Please do not apply it to high voltages yet, it could damage test equipment or cause other harm. It has barely been tested, but the information is here in case anyone wishes to help debug!

The aim of this project is to have a circuit that can be used to monitor up to a kV or so, with high input impedance, and, as mentioned, at up to around 100 kHz bandwidth. This could be useful for testing out high voltage control loops or for general measurement of high voltages.

Circuit

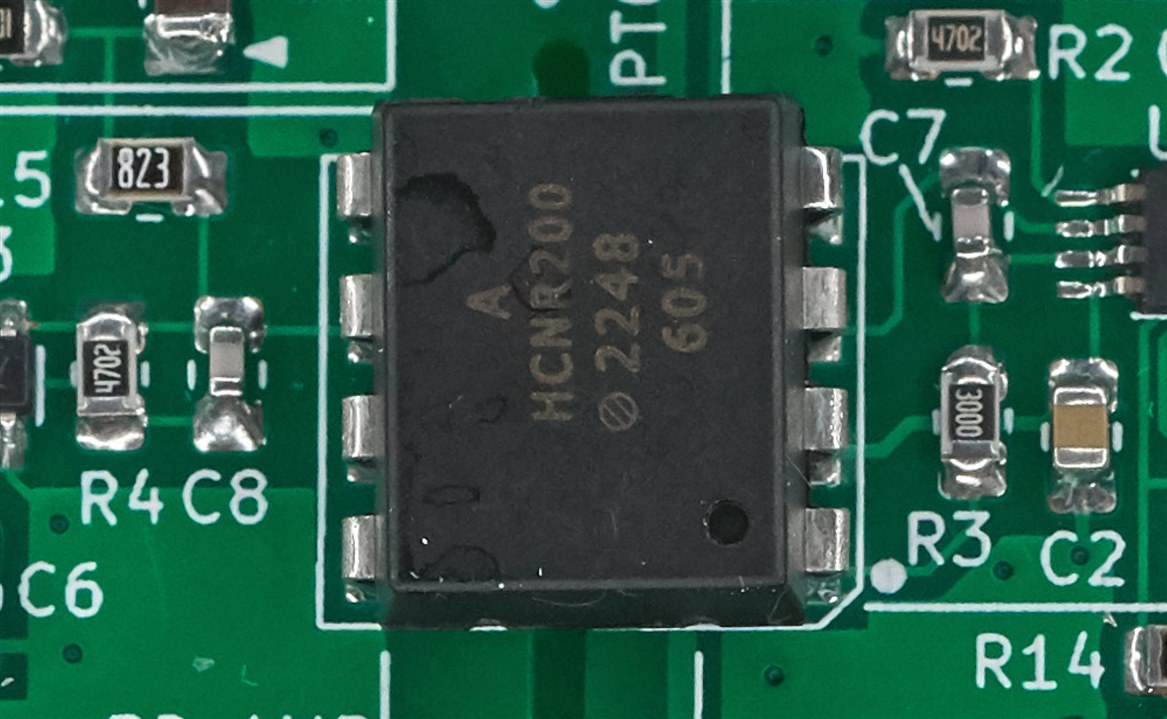

The proposed circuit revolves around a special linear optocoupler (see the HCNR200 PDF datasheet), which contains one LED and two identical photodiodes, which are used for feedback into op-amps on both sides of the isolation barrier.

On the input side, a potential divider is used to reduce the high voltage down to something that can be buffered by op-amp U1A, and then U1B is used to control the LED inside the optocoupler, using one of the photodiodes as feedback for it. OPA2197 and OPA197 op amps (PDF datasheet) are used in this project.

On the output side, the other photodiode is used, to provide a linear output voltage using an isolated op-amp. Most of the design decisions are already discussed, in the comments in the earlier blog. The circuit as shown is intended for input voltages in the range of -550V to +550V, but the range can be altered with component changes.

Building It

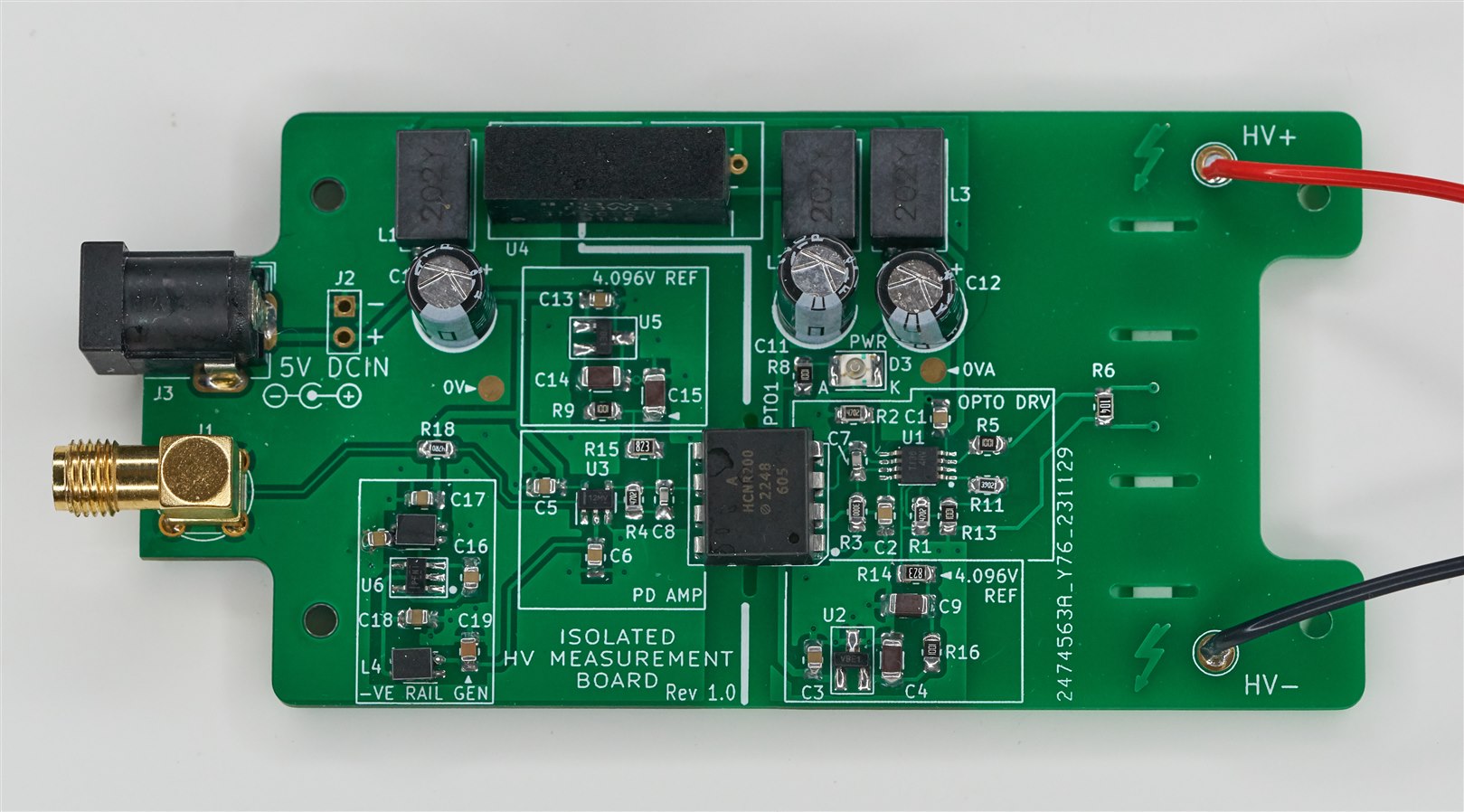

To build the board, check out the GitHub repository, which contains the PCB Gerber files, and a PDF parts list and PDF schematic . You could download the entire repo and get access to the KiCad files too. The board assembly was easy by simply printing out the parts list and following that.

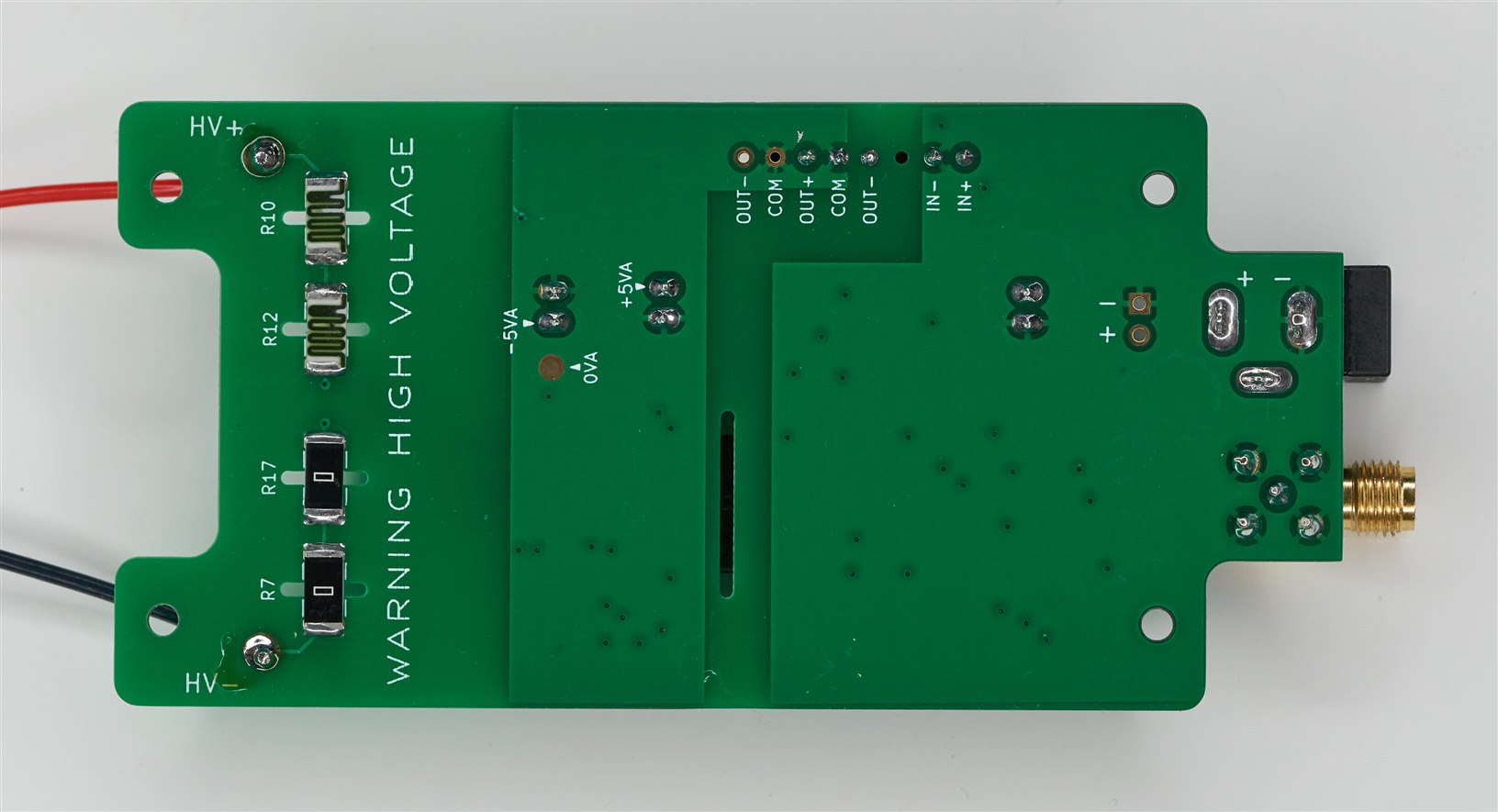

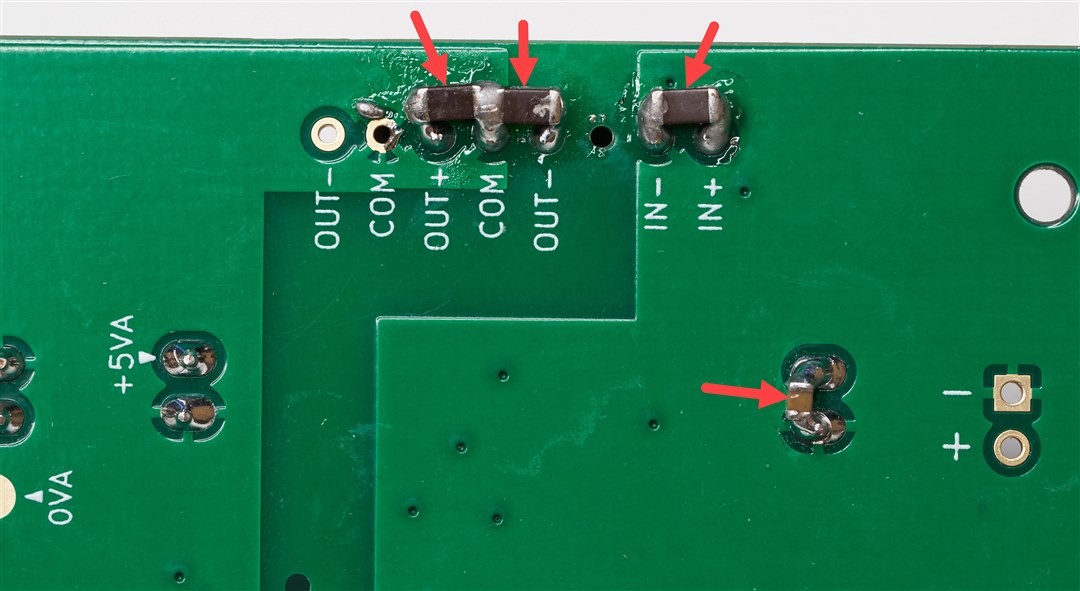

Board underside:

Issues

1. One immediate problem that will be encountered when assembling the board, is that the most important part (the optocoupler!) is wider than the footprint on the PCB : ( I don’t know how I messed that up. The fix is easy on the Rev 1 board; fold in the legs of the optocoupler using pliers, pushing the legs inwards.

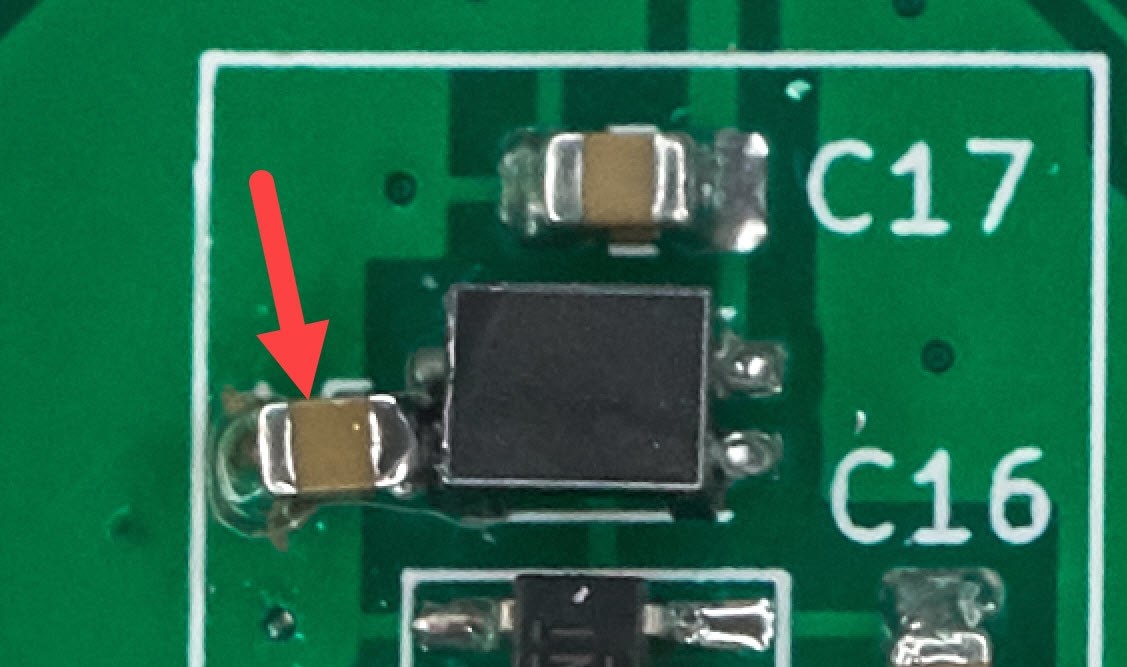

2. When powered up, the current was high! And the negative rail was not very negative. It was a silly mistake; the negative rail generator IC (TPS60403 PDF datasheet) needs an input decoupling capacitor; the impedance from the input choke will cause issues with such switched capacitor circuits. The fix was to solder on a 1uF capacitor, one end soldered to the choke, and the other soldered to 0V. I had to scratch off the solder mask on the 0V copper pour to perform this fix.

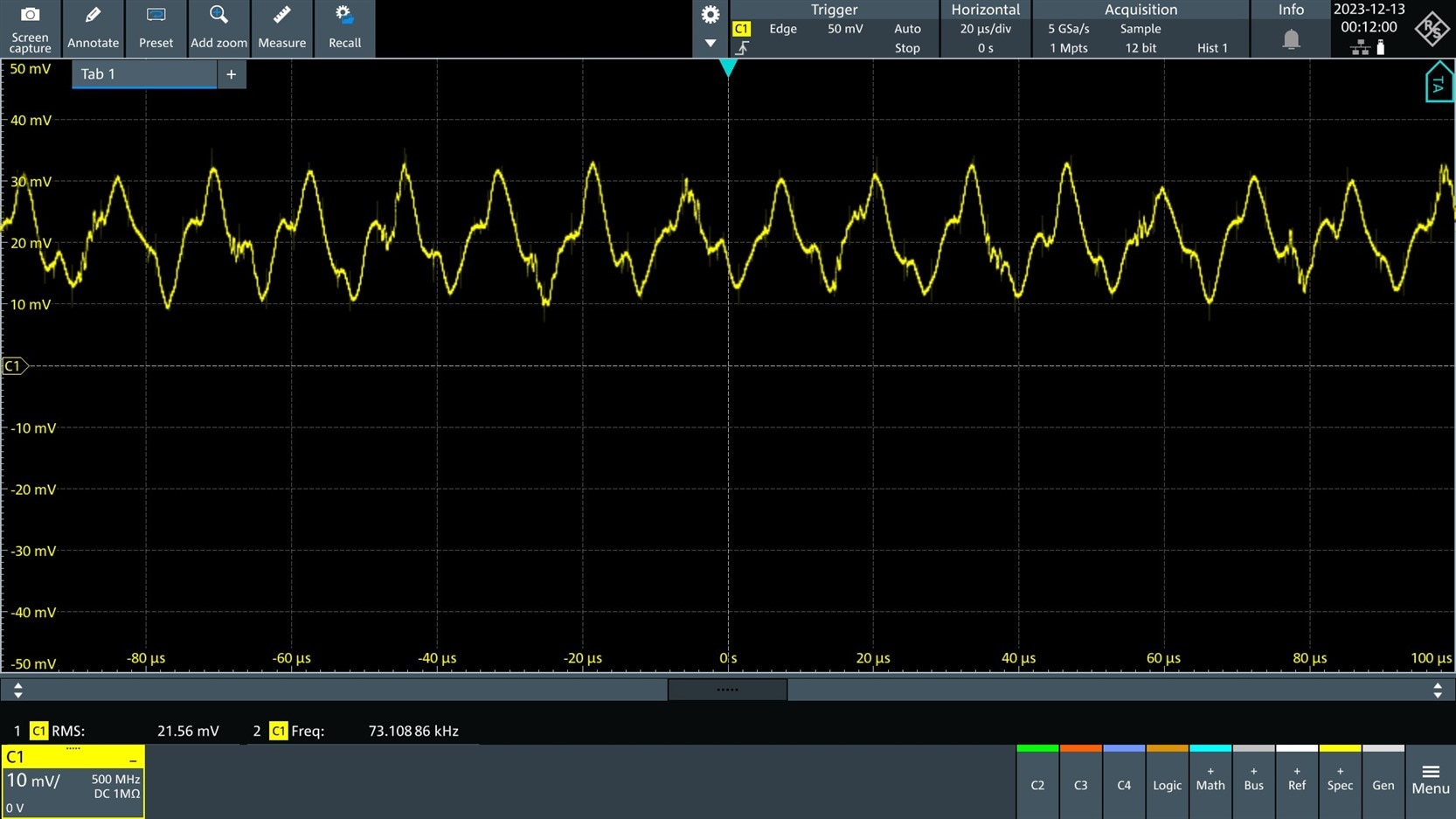

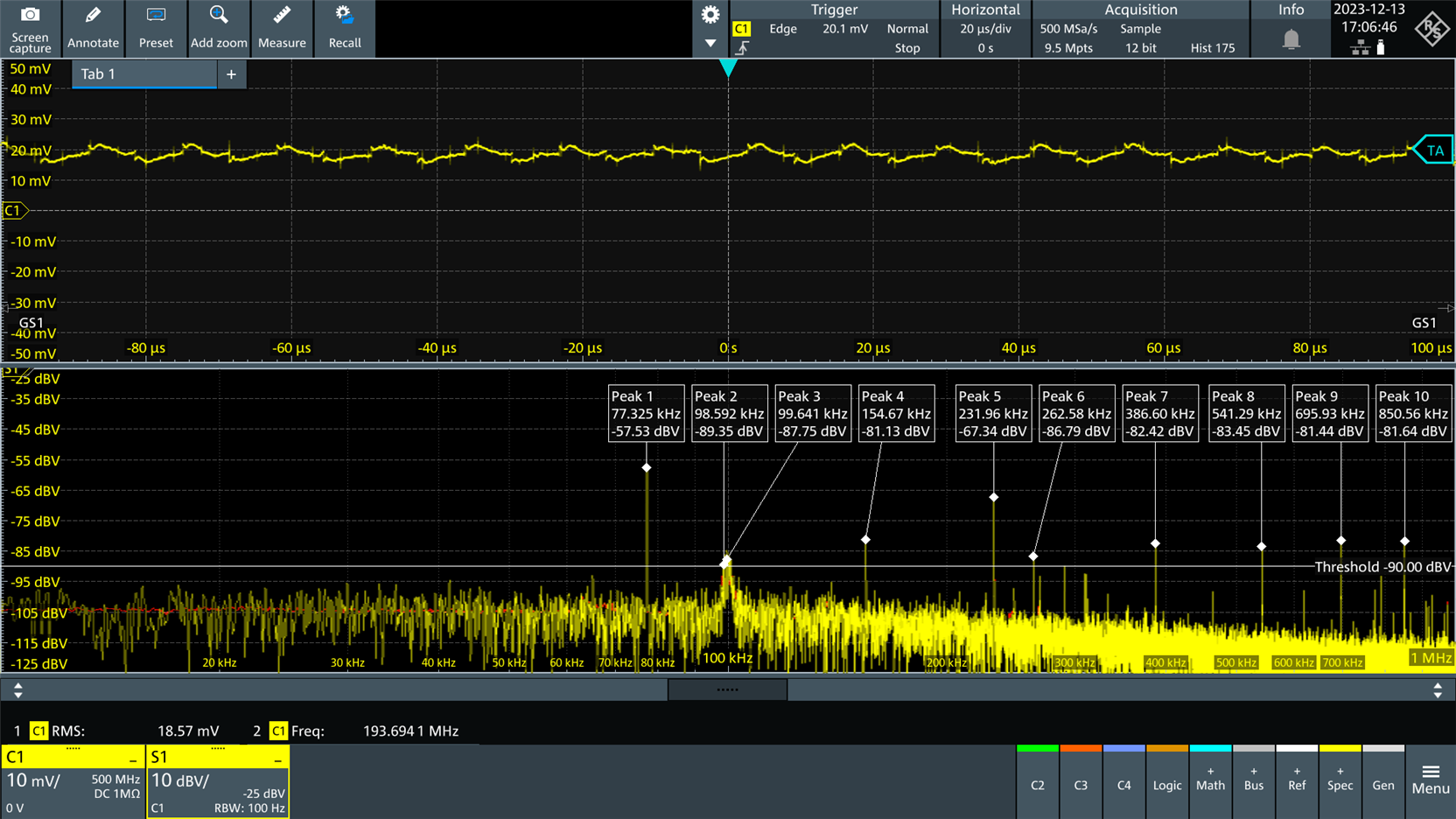

3. This issue I still need to get to the bottom of. There is a signal (about 72 kHz) on the output, at about 40 mV p-p. The DC-DC converter (TMA 0505D) is operating in this frequency region, the output voltage from the DC-DC converter is about +5.2V and -5.2V so I don’t think anything is dropping out, but I think it is being coupled at the input. I have not debugged this sufficiently yet.

Reducing the potential divider resistor R6 from 100k down to 10k certainly reduces the signal (see the screenshot below), so I think it is coupling of some sort. It may even need a new PCB layout and further distance from the DC-DC converter : ( (this is just speculation, as mentioned, I have not got far in debugging this yet at all).

However I have added additional decoupling capacitors around the DC-DC converter (by soldering ceramic capacitors on the underside of the board), but that didn’t make a noticeable difference.

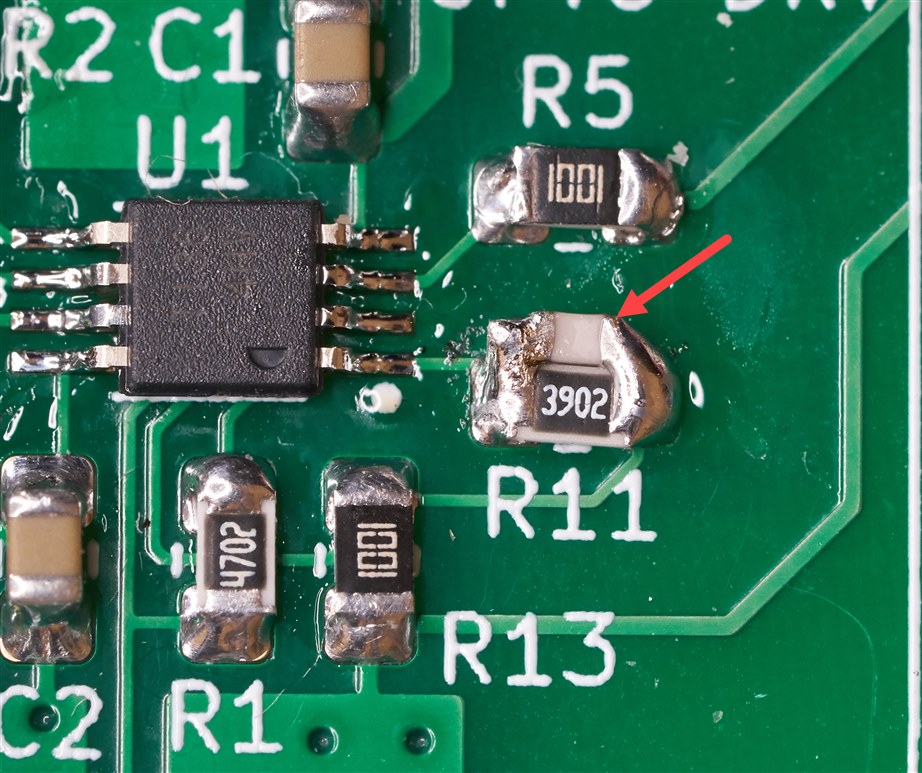

Also, it would probably be a good idea to reduce input buffer/amp bandwidth a little bit by soldering a capacitor (a few pF) across R11 in a future board layout, but for now, I tried it and there’s no noticeable difference for now, since the larger signal is so visible.

Also, it would be very good to have some sort of transient protection across the input supply rail, in case of any capacitively coupled signal from the high voltage side via the DC-DC converter.

Next Steps

I did briefly apply a voltage at the input and observed the correct output, so at least that part is functioning. However as can be seen from the scope outputs, work is clearly needed to resolve the unexpected signal issue. Also, at some point, it would be good to introduce offset nulling capability. I see a 20mV offset.

Any help would be appreciated. If you have ideas, let me know, and I can test it remotely. Or, if you wish to get your hands dirty and have some fun (hopefully) building it up (either entirely or bits of it) and troubleshooting, I have a few spare PCBs, and I’m happy to post them anywhere.

Once the board is functioning a bit better, I'll update the schematic and PCB, so that hopefully a revision 2 board can work much better. Eventually, the board could be fitted into the following enclosure if desired:

(image source: Farnell website)

Thanks for reading!

Top Comments