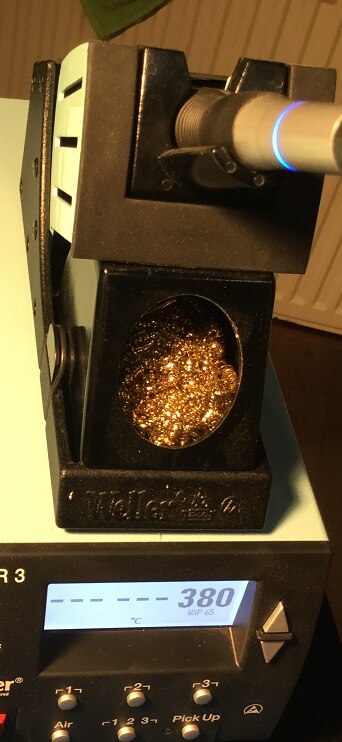

Hi I work at Newark and I'm researching kitting soldering stations and replacement soldering tips together Assuming I start with a Basic Weller 120V 50W Station(WES51 or WESD51WESD51 What tips sizes or shapes would you recommend for an entry level kit Any thoughts on tinners and sponges to extend tip life What would be the dream starter pack