3458A. People who are into precision gear, need no introduction.

I wanted one since long ago, but not having business need in it, was not worth buying, as these even used on secondary market are going for good 3000-5000$ USD. But when I saw one dead unit for 750$, I could not resist and bite it. Seller photos were quite scary, with rust all over steel frame, but PCB boards looked "okay", so I hope for the best.

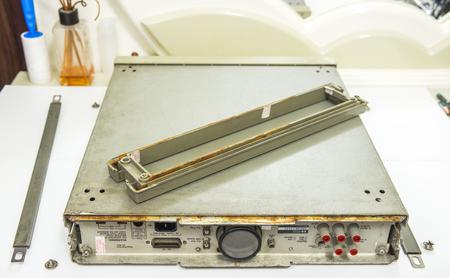

After some good money for shipping (beast is 15kg weight and size of average 2U rackmount server), I got it and did initial inspection:

* U100 processor MC68HC000P8 had paper sticker BAD (A5 board manufactured 1990)

* Missing button cap and lever for on power switch, guard switch and front/rear switch.

* Missing fuse binding post for amps on front panel

* Rust on steel chassis

* Mark "X" on mains power transformer

* Mark "X" on analog DC board 66501 (manufactured 1996)

* Error message RAM 1 LOW

* Missing voltage reference board (so calibration is meaningless, even if it's still intact in 1990 year DS1220)..

* Missing fuse holder for mains

* Damaged plastic rear panel

* No legs

* Dead fan

* Likely dead NVRAMs and lost cal as they are way too old.

Smell like lots of work, lots of debug folks.

Let's see what we are dealing with..

Always sad to see such instrument in mistreated condition. 3458A is current model, and you can get brand new one from Keysight, if you ready to fork 9.5K$, in base configuration.

Let's see what's inside..

Cover's removed:

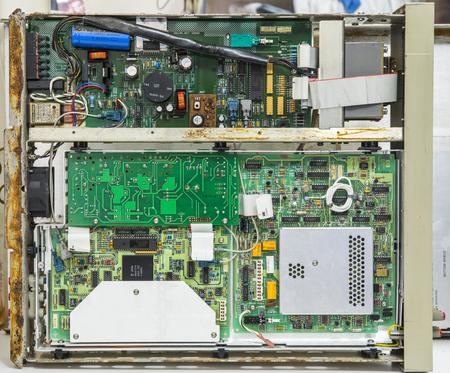

View on both sides without covers. As we can see, no A9 voltage reference with Linear LTZ1000 present. New A9 reference module from Keysight runs for 700$, but hey, I don't need go that way. I had own LTZ1000(A) based references, on which I spent multiple hundreds, and on second source there is eBay, where these references popup for sale like mushrooms after rain. I snagged one of those already , should arrive somewhen next week. So we covered here..

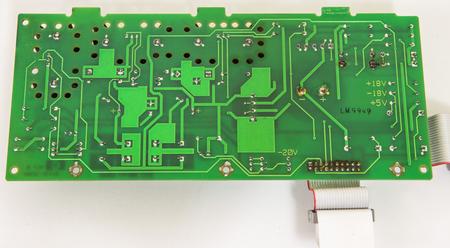

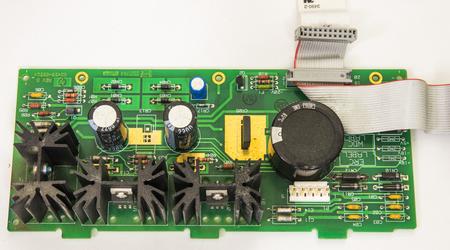

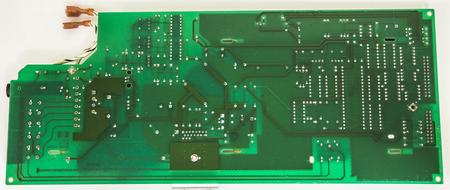

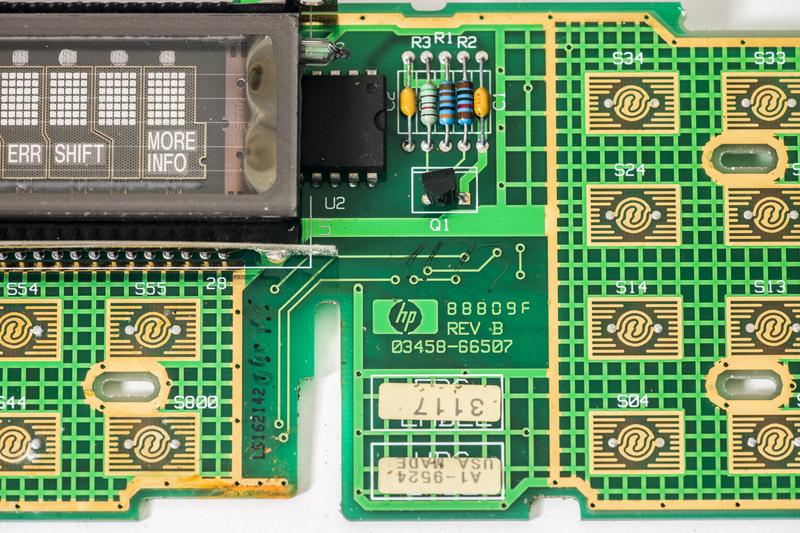

Inguard PSU. Some PCB damage around CR12 visible.

Outguard primary PSU. All seems ok, but need cleaning..

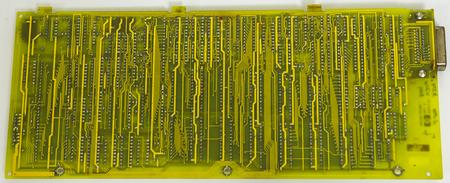

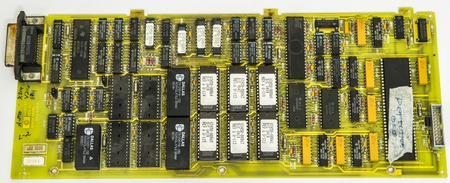

68000 CPU, RAM, ROM and digital logic, board A5. Dated 1990, while rest of analog PCBs dated 1996.

Probably seller changed digital PCB afterwards?

Removing inguard PSU for now, adding jumpwire instead of fuse (don't have suitable cap), turning on...

It's works!.. Well, not really  Analog side completely disconnected and unpowered at this moment, just check digital and power sections first.

Analog side completely disconnected and unpowered at this moment, just check digital and power sections first.

Nice and bright VFD, which is good, as it's hard to get replacement for those.

Now will remove Dallas NVRAMs , and solder sockets instead, so we can troubleshoot this RAM 1 LOW.

Front panel must be removed in order to remove mains transformer.

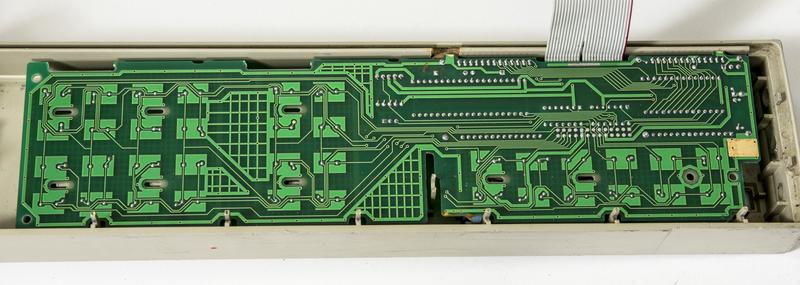

Looking good, just minor cleaning required..

Frontpanel PCBA label and front binding post terminals.

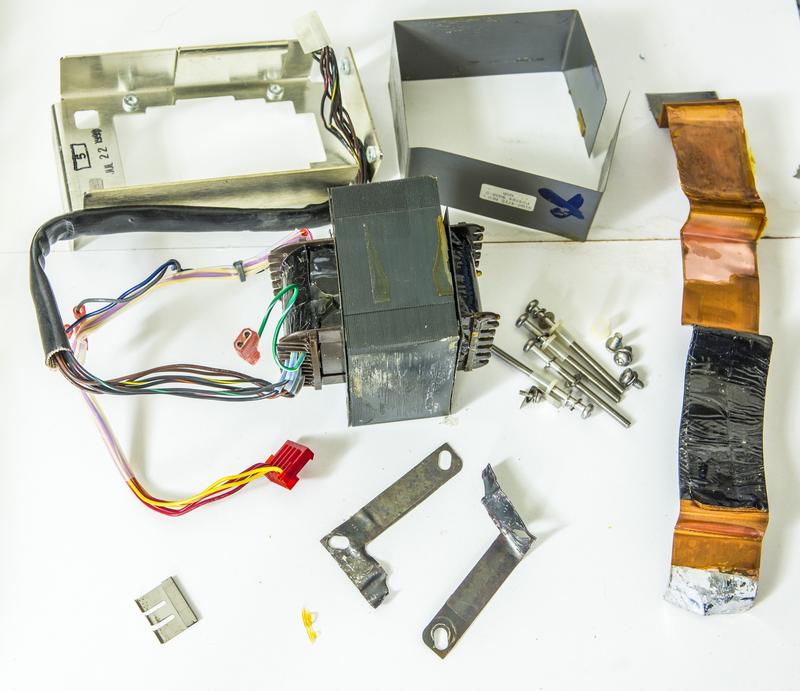

Now, we can take transformer out. I tried to open it up, but it's all covered in lacquer, and my patience run out quickly after wasting a hour trying to take it apart.

Transformer have two winding sections, primary with secondary for outguard +5V rail (goes to digital board and front panel, that's why it's working).

Second section for inguard supply is inner bobin with two secondary windings (one with center tap to generate +18/-18 and second for +5V analog).

This windings in my transformer are shorted together!

I would not trust repaired/rewinded transformer in such an instrument anyway, so going to make Agisight richer for $337 to get new transformer.

In case someone got FALSE impression that buying dead HP 3458A and fixing it would be cheap way to get yourself 8.5-digit DMM, think again.

Here are expenses on my unit already so far:

Add calibration (let's say you go full tilt, standard's grade cal $2660), and you looking into healthy 4.4K$, for which you can get working and likely even calibrated 3458A from second-market, if you patient and shake trees good enough.

Also you can see I cut few corners here and there with parts from eBay, as if you go with all original parts from Keysight, it will be much more (Reference board alone is 700$, like mentioned before).

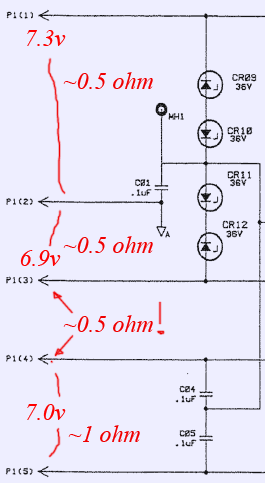

Since I wait for new transformer to arrive, how can we test inguard supply to confirm it's OK?

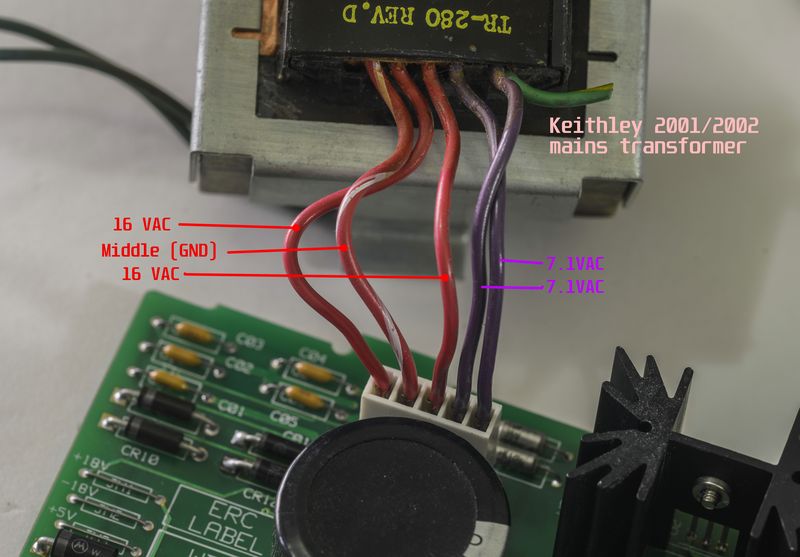

I have a "solution". From previous Keithley Model 2001 repair projects I have one extra power transformer, which happen to have same voltage outputs, as HP one, just at lower power rating. But since we connect only inguard supply A4 board, we don't need full power to check LDO's operation. So let's replace blown zeners and test A4 PCBA with properly wired Keithley mains TR-280 transformer. Never know which parts could ever come handy, eh?

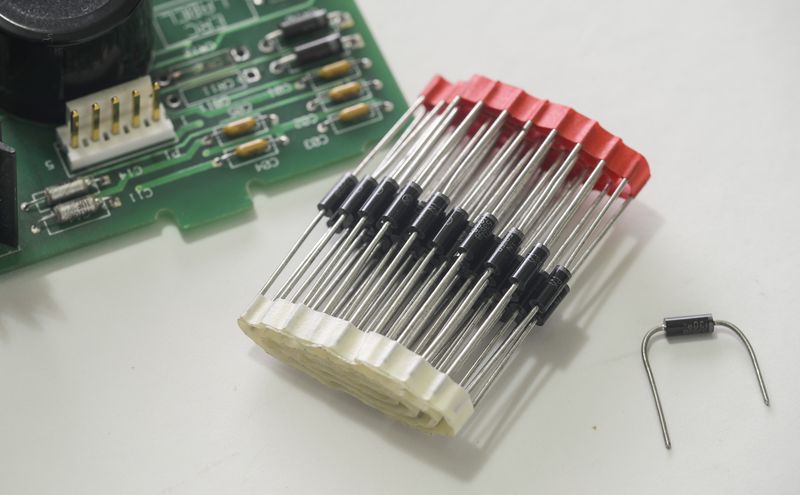

But first, replaced original CR11,CR12 with fresh zeners (got 50pcs from eBay, just few dollars with free shipping).

Cleaned board both sides, everything else look intact and good.

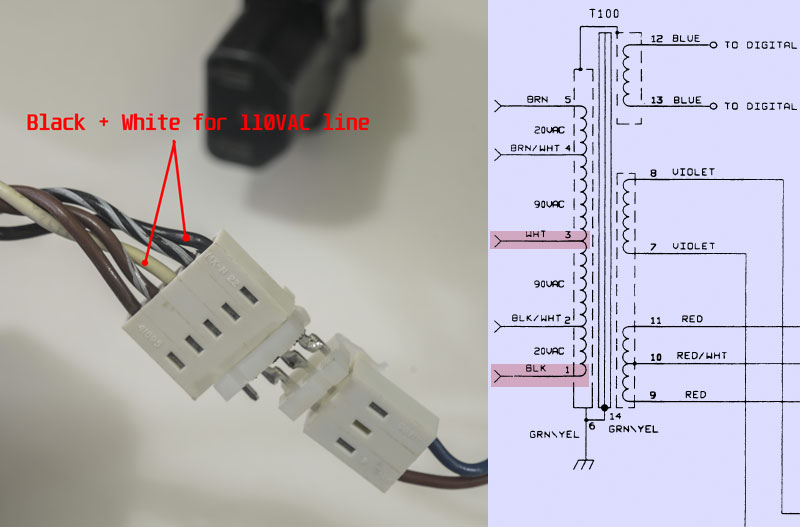

Now can connect input IEC plug socket to transformer's primary (since I need 110VAC, I used WHITE + BLACK wires).

Keithley used same type of 5-pin connector, but with different pinout. Secondary connector need rewiring as on photo above. I powered transformer separately and measured VAC voltages on secondary, without A4 board connected, to make sure all voltages correct.

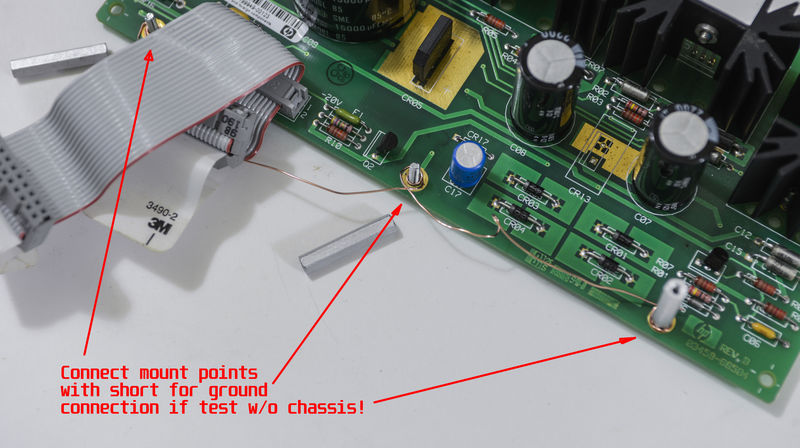

If you see schematics of A4 board in 3458A Multimeter Component Level Repair Manual, you may noticed MH1,MH2,MH3 connections. These are connected directly to guard frame in 3458A's chassis, which is acting as mecca star point for GND potential. Since I testing board separately, not mounted to chassis, I needed to connect these MH* points together with copper wire. This will be our ground point for measurements as well.

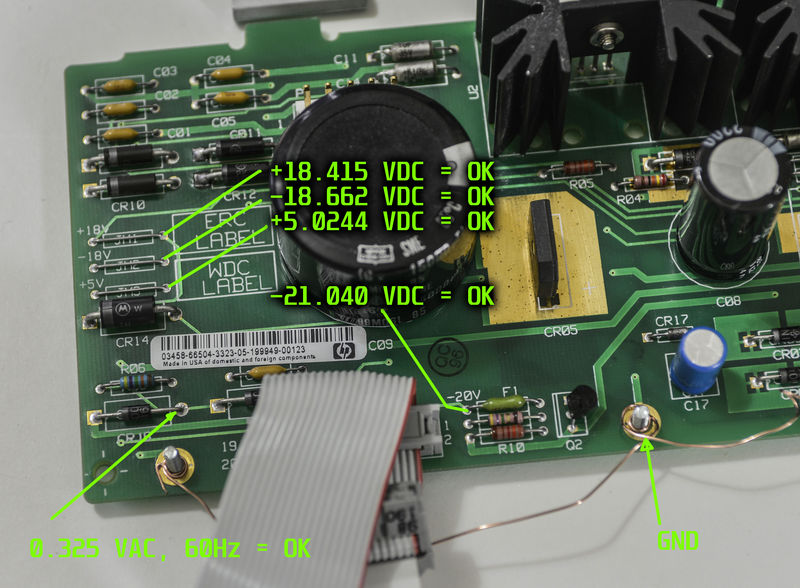

Apply power to transformer, and if nothing smokes, test output DC voltage.

There are nice labels near test points, telling us voltage test points location.

All voltages are OK, also 0.325VAC 60Hz signal to read mains frequency is OK too.

Repair of A4 inguard power supply now complete.

I also got used bezel off eBay in good condition, to save some money on this project, as it's just mechanical part to keep meter in one piece.

New one on bottom side, old busted rear bezel is on top.

Original unit's bezel had three out of four screw mounts destroyed, so it was not holding well.