Now comes the part of the build where everything visually starts to come together.

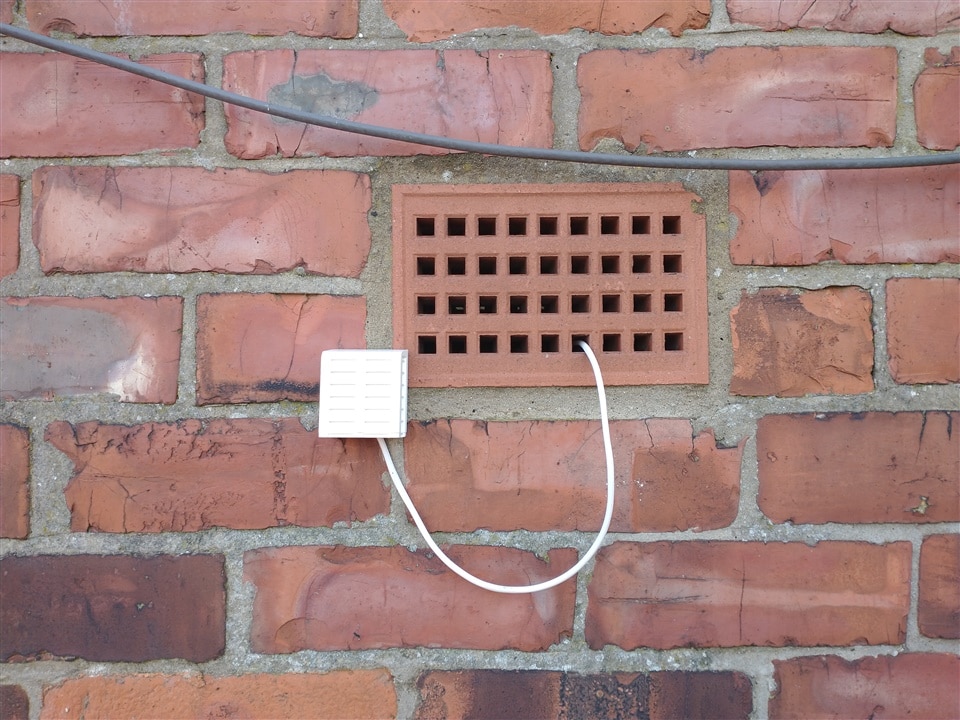

The idea of the Cool Wave project is that it can be instilled over any opening to a property. This may be a window, ventilation hole, or even a cat flap (subject to the cat’s approval, obviously). For my house I will be using an air brick. My house has several and I am using this one because I can feed a wire thought for the external sensor without needing to drill any new holes in my property.

The Main Enclosure

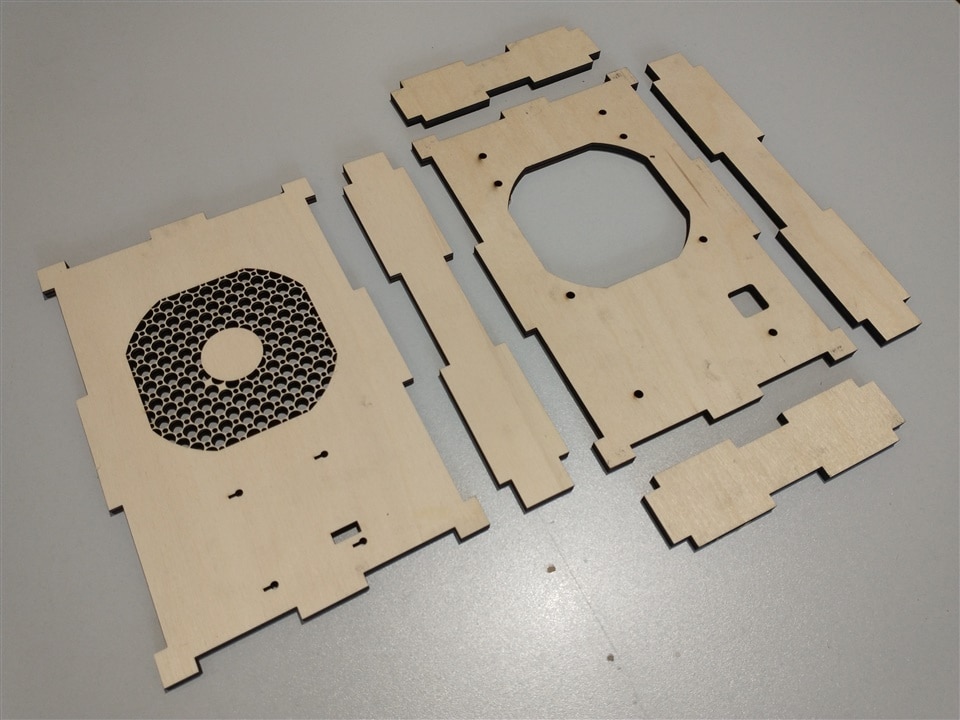

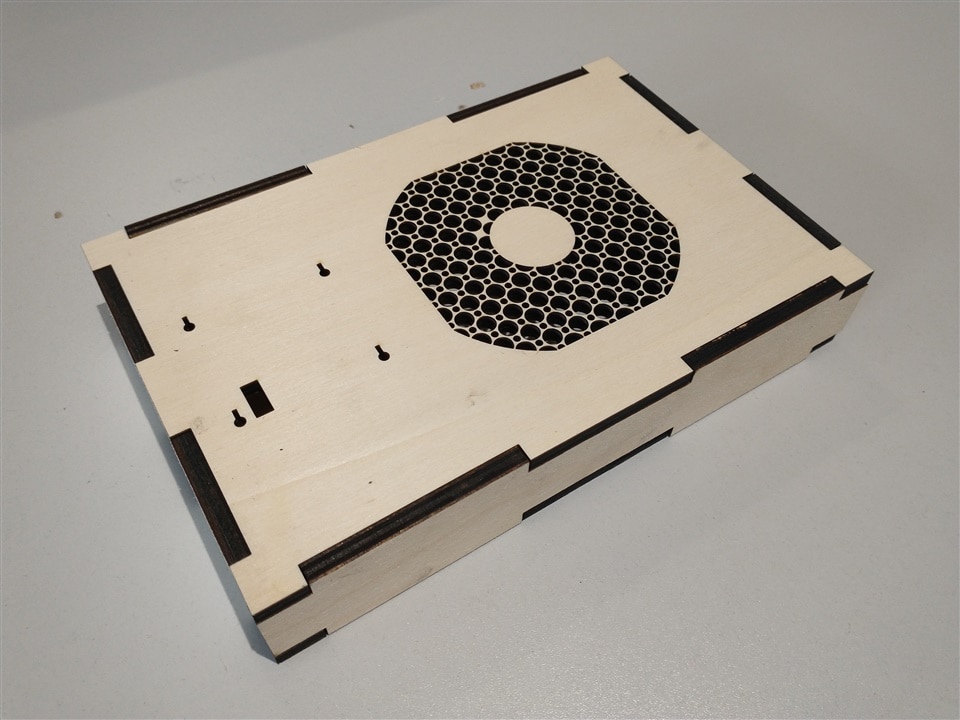

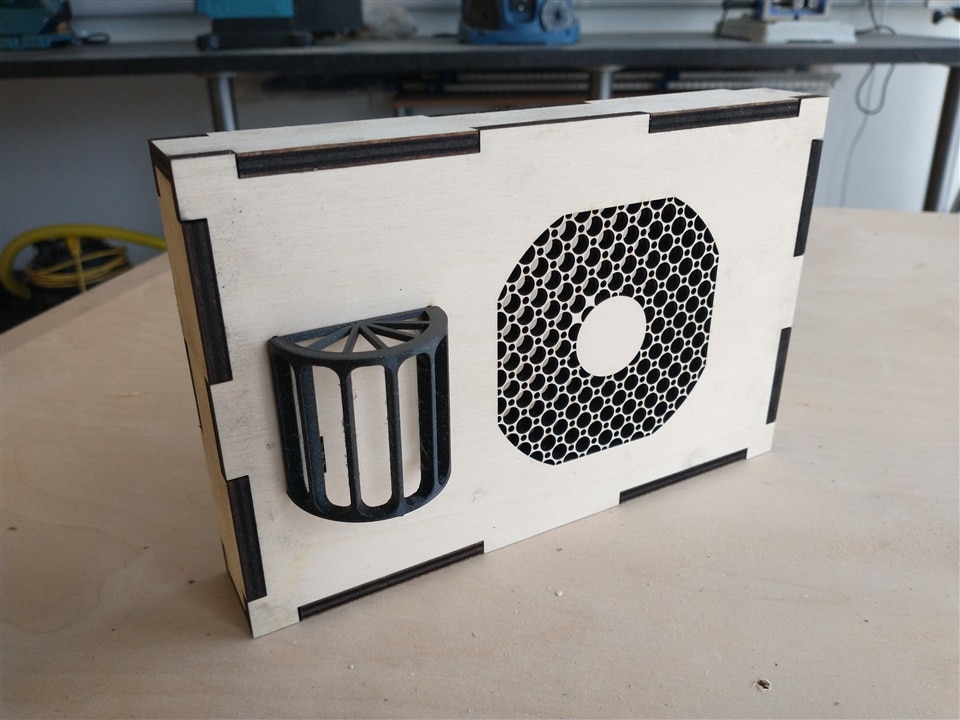

For the main body of the Cool Wave unit I decided to use some plywood offcuts that I could laser cut and the glue into an appropriate enclosure. My intention is to paint the cover and use silicone sealant to remove any leaks, but I will do this after I have tested the design and have the code debugged.

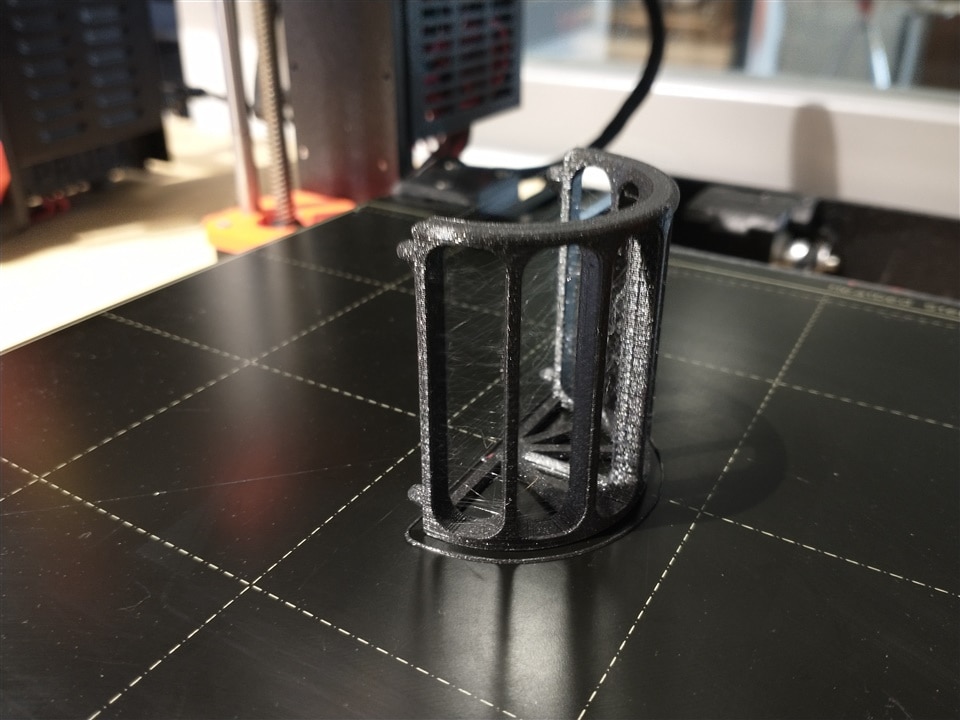

There is also a 3D printed guard to protect the internal sensor, but this is purely optional.

After cutting the parts they are glued as photographed with the front panel being a comfortable force fit.

| {gallery}Cool Wave Main Enclosure Build |

|---|

|

IMAGE TITLE: Laser cutting the enclosure |

|

IMAGE TITLE: Enclosure parts |

|

IMAGE TITLE: Enclosure part assembled |

|

IMAGE TITLE: The sensor guard |

|

IMAGE TITLE: Enclosure fully assembled |

I have included the files for the design here. I spotted a couple of missing holes in my design that you may spot in the photographs, but they have been fixed in the files. I hole for the power supply needed manually drilling where you need it.

The External Enclosure

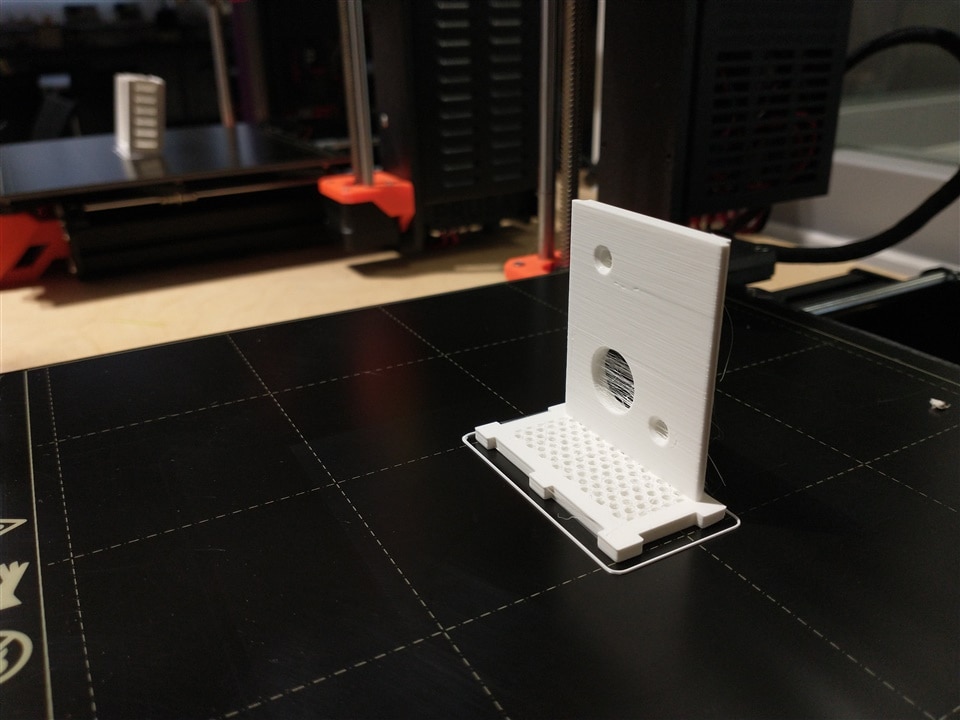

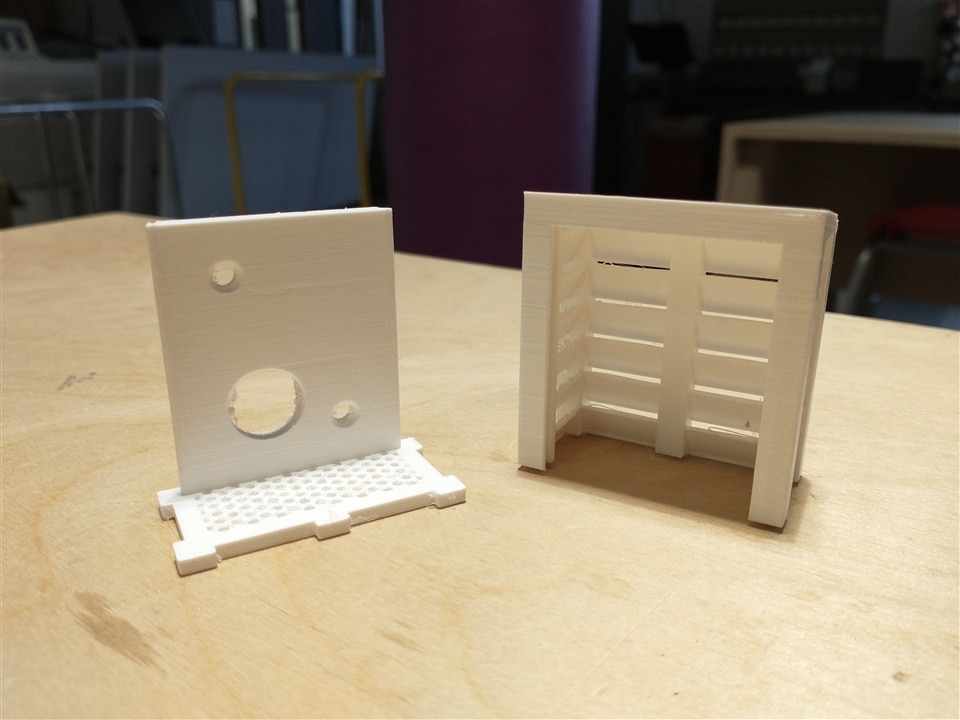

The outside sensor needs to be housed so air can get to it, but it is not susceptible to direct sunlight, wind or rain. I have taken a few design tips from weather station designs for this one. It is designed so it can be printed in just two parts and slide together once mounted on the wall.

| {gallery}Cool Wave External Enclosure Build |

|---|

|

IMAGE TITLE: 3D Printing the back |

|

IMAGE TITLE: 3D Printing the front |

|

IMAGE TITLE: The front and back separate |

|

IMAGE TITLE: The front and back assembled |

The files to print your own are here. It may seem odd to print one have at that odd angle, but I have designed it that way so the roof will allow rain to drip off instead of evaporating, while not needing to waste materials by printing supports.

Installing the Electronics

Now all the electronics from the last blog post need to be installed in to the enclosure.

It is worth noting that there is no wrong direction to mount the fan. We are circulating air through the house and not creating or destroying it. If we suck air in, the equivalent amount of air will be pushed out through the various cracks and other vents in the building. If we blow air out then more air coming into the house in the same way.

Everything else now slots into place. I have not gone overboard in making the layout overly neat. If I had more time I would make some custom mounts for the modules, but I do not so I will not. If this works well I am likely to design a custom board with everything laid out appropriately so I can consider this as the prototype.

Installing the Finished Hardware

To mount it to the wall I inserted some custom plugs that I screwed in to and can drill out if no longer required. The layout of the enclosure has been measured to fit over the air brick’s holes as efficiently as possible so finding the location of the plugs when mounting to the wall was easy.

One thing I did not realise until after I had started the installation is the holes get slightly smaller as they go into the wall. Only a little, but enough that I needed to change the connector going to the external sensor (most photos show the original). Also I was surprised that the air brick on the outside of the property was not exactly parallel with the inside, so the wire came out through a different hole than I thought it would.

Now that is done everything is in place and installed. It is effectively working with some basic test code and ready for the next heat wave. I am still improving the firmware and that will be my next blog post.