In this post, I will write about how I use the Arduino board, the DFRobotic shield and the TE connectors

1. Connections overview

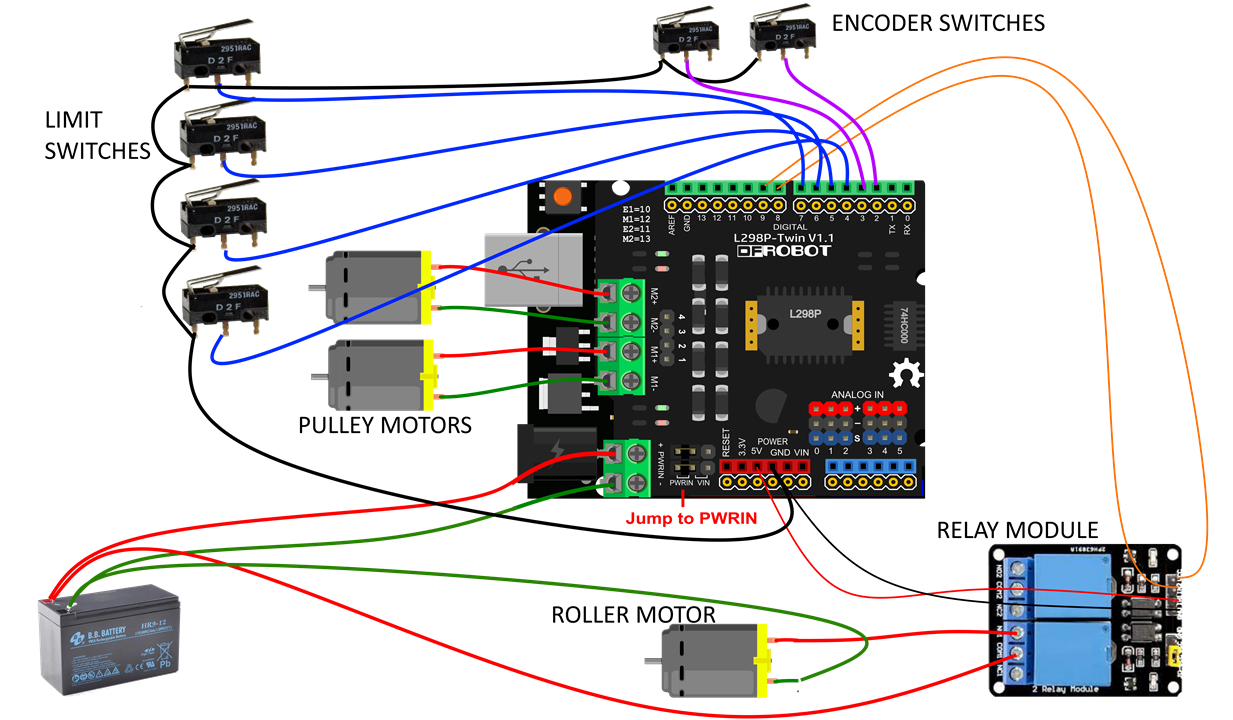

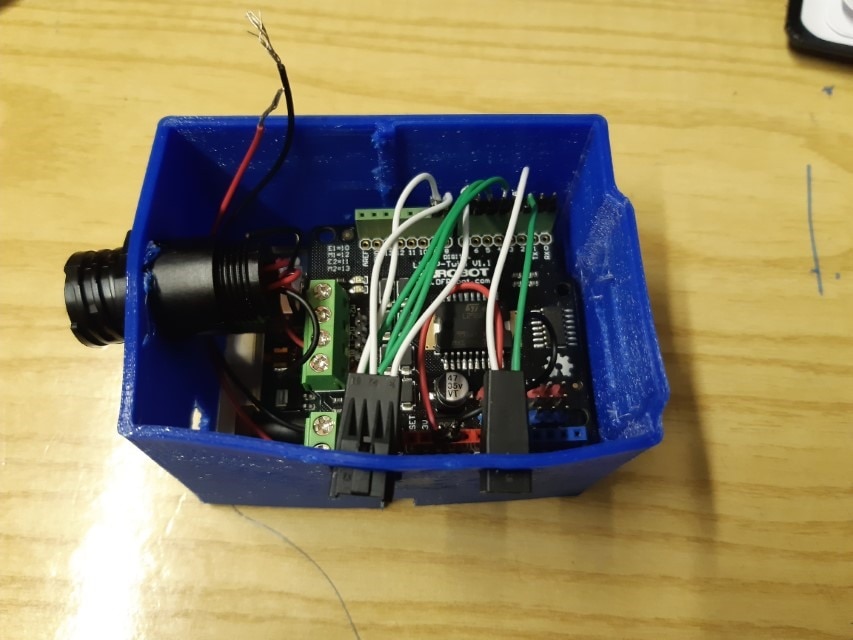

Picture below shows the components and the wiring

Main components are

- Arduino Uno R3 board

- Gravity: 2 x 2A Motor shield for Arduino to control the motors that move Rullit around

- 2 relay module to control the solenoid valve (to dispense water and detergent) and the roller motor

- 4 limit switches (front, rear, left and right) to stop Rullit when the edge of the PV modules has been reached

- [Experimental] 2 limit switches to implement a rough encoder and detect the real length of thread winded or unwinded. This could be useful because, at low PWM values, motors may stall and this may add an error that accumulates over time. The first release of the robot will not include this feature. I will evaluate performances and decide whether to implement it or not

2. Connectors

I planned to use the following parts included in the challenger’s kit

These are the parts [thanks dougw for the very detailed list of parts included in the challenger's kit]

I am not good at all in taking close-up shots. robogary wrote a great post with wonderful pictures about the crimping process

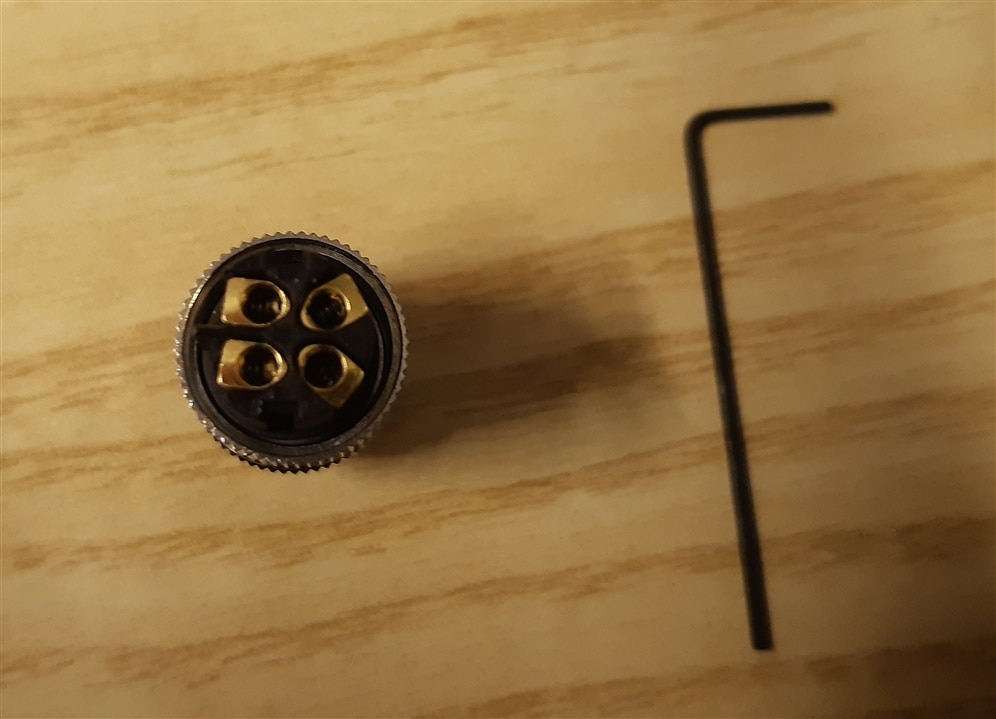

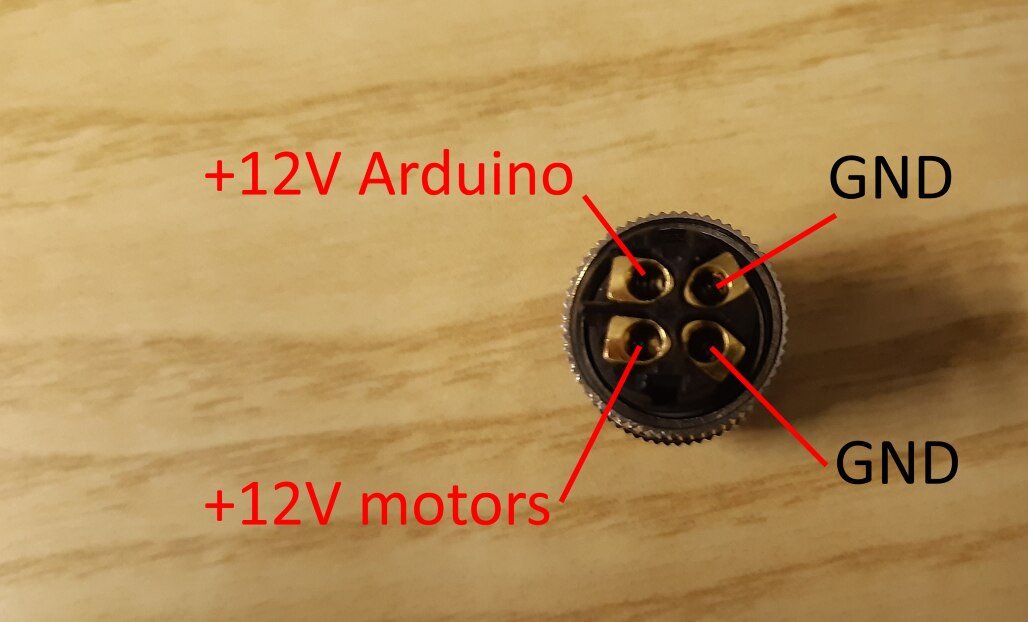

2.1 Connector N. 1: Power supply

The metal M8 connector will connect the battery to the Arduino board.

SKU: 71AJ9362

Manufacture part#: T4011019041-000

Description: Sensor Connector M8, Male 4 positions, Cable mount

SKU: 71AJ9360

Manufacture part#: T4010019041-000

Description: Sensor Connector M8, Female 4 positions, Cable mount

This connector has four pins and screw terminals – the wrench to tighten the screws is included

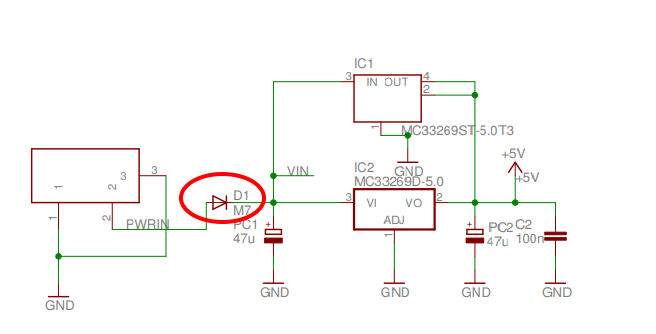

Looking at the power section of the Arduino Uno R3 board, it looks like it can not handle all the Amps the DFRobot motor shield can handle. The DFRobot shield is rated for a maximum current 2 x 2A, but the schematic of the power section of the Arduino board shows that a diode is mounted to prevent damages due to inverted polarity

I can't read the actual code of diode on the Arduino board, but a typical diode can handle a maximum current of about 1 A. For this reason, I will use two separates 12V power supplies: one for the Arduino board (through the jack connector) and one for the DFRobot shield (through the two wire screw terminals)

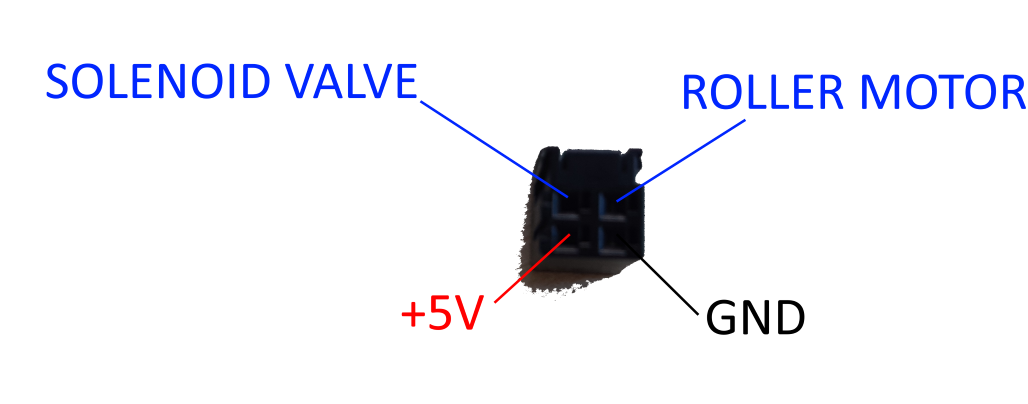

2.2 Connector N. 2: Relays

The second connector brings power supply and control signals to the relay board. Relays will switch on and off the solenoid valve and the motor that drives the paint roller

SKU: 53AJ9498

Manufacture part#: 1-2366515-4

Description: DYNAMIC D1000 SLIM, WIRE-TO-WIRE CONNECTOR, receptacle : 4 positions, 2 mm pitch key 1

SKU: 53AJ9501

Manufacture part#: 1-2366600-4

Description: DYNAMIC D1000 SLIM WIRE-TO-WIRE CONNECTOR pin housing : 4 positions, 2 mm pitch key 1

SKU: 53AJ9515

Manufacture part#: 2367819-2

Description: DYNAMIC D1000 SLIM WIRE-TO-WIRE CONNECTOR crimp contact pin

SKU: 53AJ9511

Manufacture part#: 2367817-2

Description: DYNAMIC D1000 SLIM WIRE-TO-WIRE CONNECTOR receptacle - crimp contact

Here is the pinout of the connector

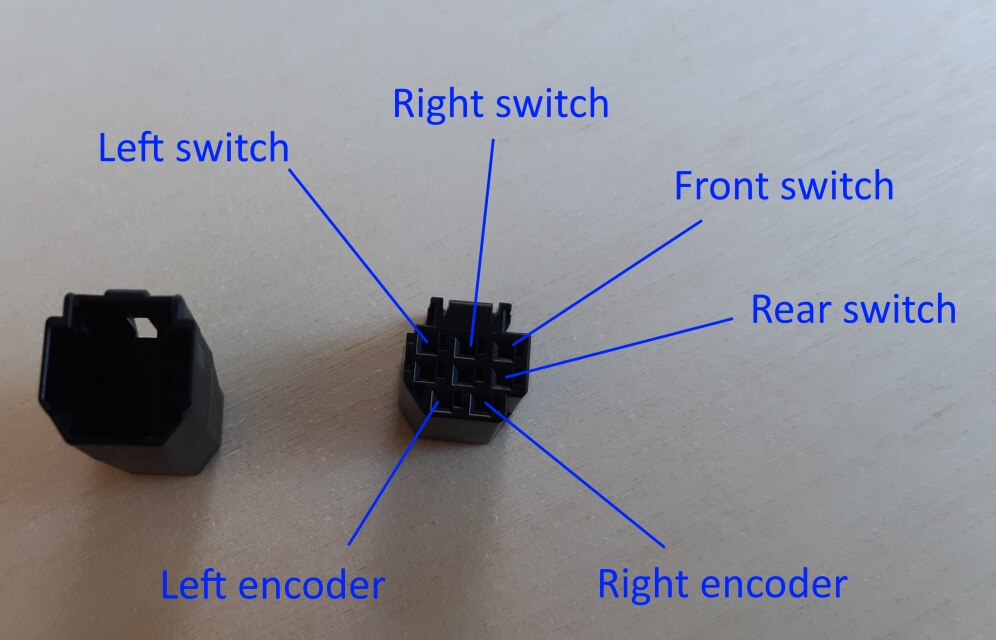

2.3 Connector N. 3: Inputs

The third connector brings input signals from encoder and limit switches.

SKU: 53AJ9500

Manufacture part#: 1-2366515-8

Description: DYNAMIC D1000 SLIM WIRE-TO-WIRE CONNECTOR receptacle : 8 positions, 2 mm pitch key 1

SKU: 53AJ9503

Manufacture part#: 1-2366600-8

Description: DYNAMIC D1000 SLIM WIRE-TO-WIRE CONNECTOR pin housing : 8 positions, 2 mm pitch key 1

Here is the pinout of the connector

NOTE: because the kit includes only 10 contact pins and housings, I will re-use the ground signal available on connector N.2

2.4 Connector N. 4: Motors

The fourth connector brings power to the DC motors that drive the pulleys

SKU: 46F314

Manufacture part#: 206153-1

Description: CPC Series Circular Connector 4 pin contacts

SKU: 44F8386

Manufacture part#: 206060-1

Description: CPC Series Circular Connector 4 receptacle contacts

SKU: 50F554

Manufacture part#: 201330-1

Description: CPC Type II Series 20 AWG pin contact

SKU: 50F553

Manufacture part#: 201328-1

Description: Multimate Type II Series 20 AWG socket contact

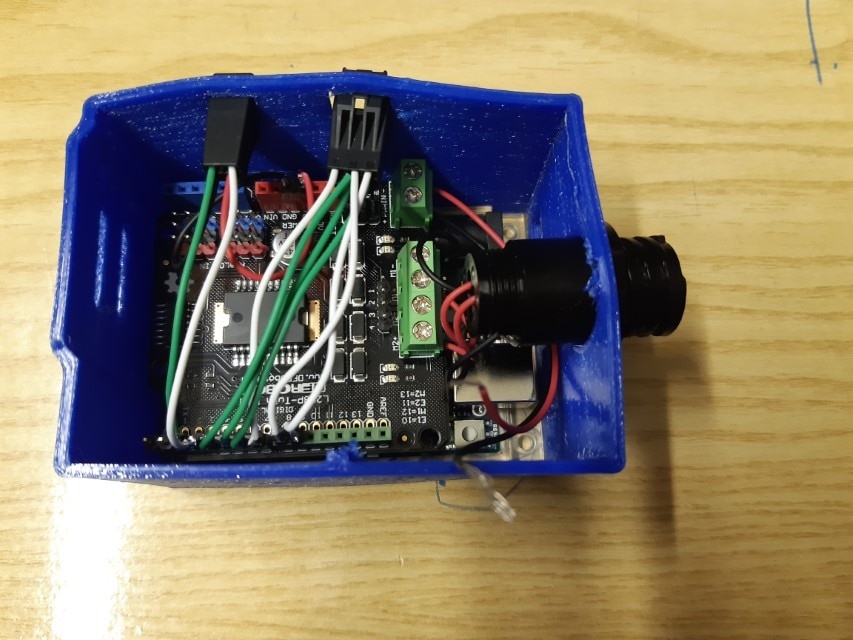

3. Prototype

This is the first prototype of the Arduino Uno with the case and the connectors in place. Unfortunately, I ordered the wrong filament (I ordered a TPU filament instead of PLA), so the case is flexible. I will print the final case as soon as the correct filament is delivered

|

Prev: Mechanical design |

Next: Building the robot |

-

DAB

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

DAB

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children