Hey everyone,

I'm not a mechanical engineer by any stretch on anyone's imagination. I have one mechanical design issue that I'm not sure how to approach. I kind of know the theory, but I have no idea how to approach it practically.

Here's the problem...

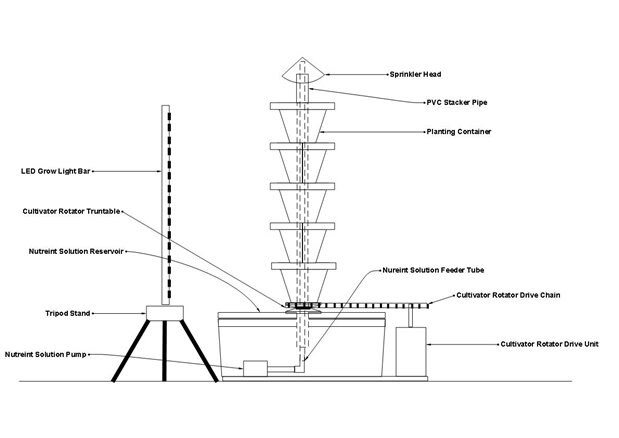

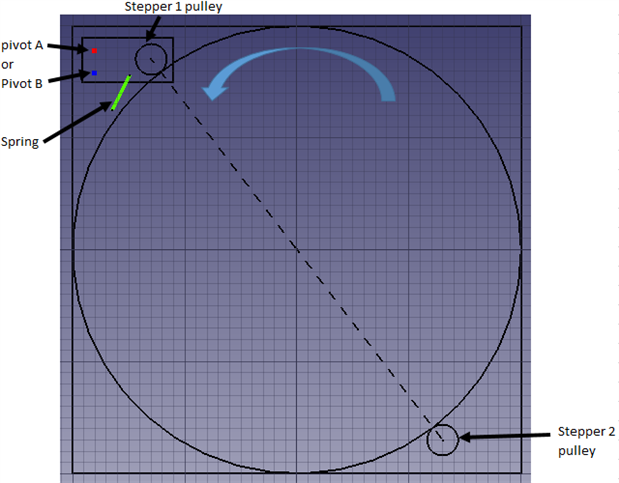

I have a load, my cultivator unit, that will be about 3' - 4' tall, maybe 12" to 18" in diameter and weigh between 20 and 40 lbs. The whole thing will be mounted on a lazy susan style turntable. The plan is to have a gear or pulley at the bottom that will be used with a hight torque stepper motor, and chain or belt, to rotate the cultivator. I'm using a stepper motor because they are pretty efficient and can be controlled very easily at very slow speeds. I want the rotation speed to be maybe 3 to 4 revolutions per day. A stepper would work well for this I think.

I have no idea how to properly size the motor. I see them speced at anywhere from 10s of oz-in to 1000s of oz-inches of torque. I get the concept of torque being rotational force. And that required torque has to do with acceleration time up to the desired RPM. But I have no idea how to relate this to my requirements.

I'm a 'puter software with some dangerous electronics knowledge guy! HELP!!! And feel free to tell me this just a stupid idea and I should be using a washing machine motor or something if that's the case.

For reference, here's a drawing of the rig. Note the drive at the bottom right. Please excuse the misspelled labeling. I haven't gotten around to correcting it yet. lol...