Hi Ben,

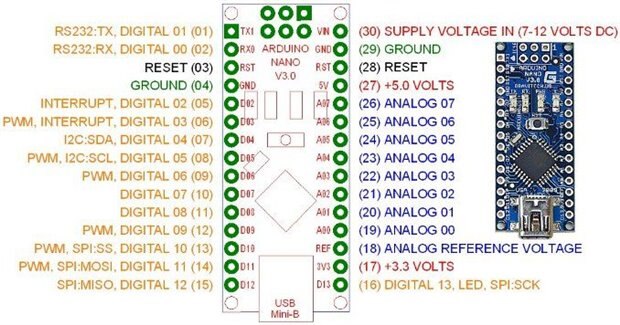

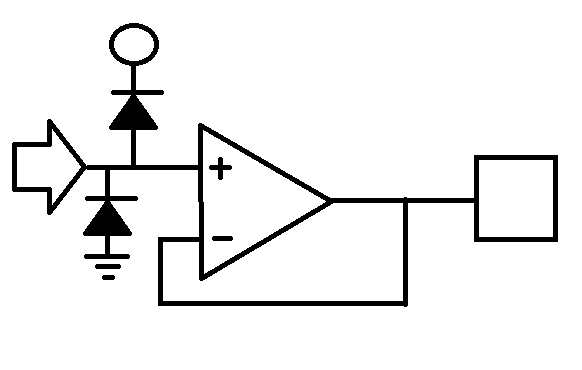

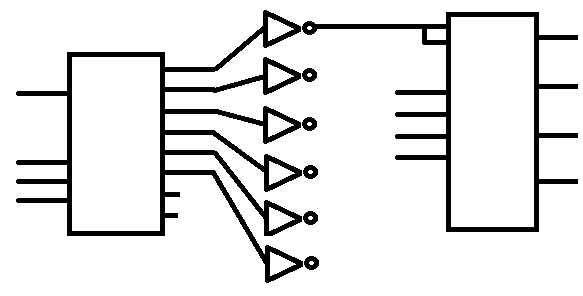

I am a programmer with a very small amount of skill with circuits, and am looking to create a platform for an engine management system, using an Arduino Mega 2560. I had done a bit of the coding, when I ran into some timing issues with the built in Arduino manager, so I switched over and started using AVR Studio and a programmer to go directly to the chip itself. The code looks like it should work ok, but now I need some additional circuits to handle the energy levels of coils and injectors (Something like IGBTs). Sensors are being run through simple dividers (no protection yet), and cam and crank inputs are through a simple comparitor

Let me know what you think,

Jack