I’ve been using the same PCB design software for over 20 years (Easy PC) and it’s served me well during that time. It’s had an update pretty much every year and it can still load files from 20 years ago. It hardly ever crashes and I’ve probably designed more than 300 boards with it.

So why am I writing this blog about Kicad ?

It’s because there is so much talk about KiCad and how good it is – and two other reasons that are becoming more and more important.

Easy PC is Windows only but Kicad will run on Windows or Linux platforms – this is becoming important to me because I think my patience with Windows is close to exhausted. I feel the weight of the enforced changes of OS, the constant pushing of their AI and cloud stuff and the general customer contempt crushing me. I don’t think I’m ever going to run Windows 11 as my main OS.

The other reason is that the popularity of KiCad means that more and more of my customers are likely to be using it, and because it’s free to install even those who don’t can easily load it to share a design if they wish.

There is a there, slightly off the wall reason. Altium, the biggest player in the mid-price sector I believe, has been bought by Renesas – so as far as I am concerned is no longer a sensible choice of PCB Cad supplier. I expect a lot of other people to react the same way.

So I decided that the next non critical internal (ie not for a customer) design that I would use KiCad.

I installed version 7 on a Linux machine and never quite got a suitable opportunity but recently I was looking at a broken HP59313A. This is a 4 channel 12 bit ADC capable of a staggering 12 bit resolution and 200 samples per second with HPIB (GPIB) bus interface. It is very old (47 years), cost me very little and doesn’t work. The first fault I found was a dead LM309 voltage regulator in a TO3 can. These parts are no longer made and although second hand (or even claimed new and unused) parts are available they cost silly money and can’t be trusted.

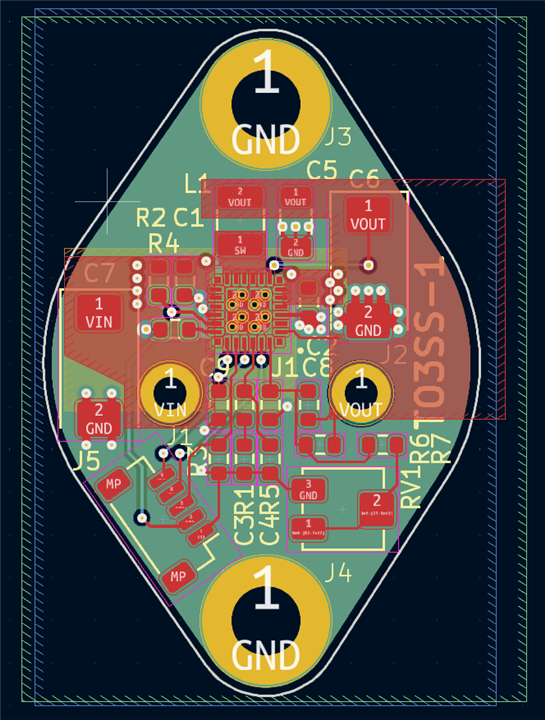

As you can see from the picture I bodged in a 7805 which got the 5V supply up but didn’t get the box working. But I though that making a TO3 shaped PCB with a regulator on it would be nice because this is not the first dead LM309 I’ve seen.

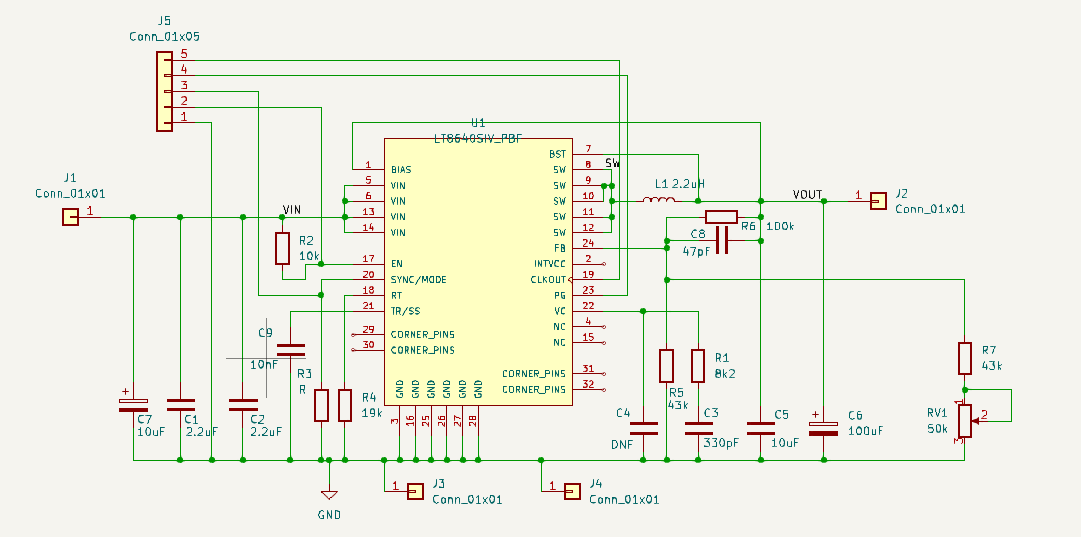

At first I was thinking of a linear regulator but looking on the web I found a design using a switching regulator. It was done a long time ago and used a rather dated switcher. While I was looking an email flyer form Linear Technology/Analog Devices turned up promoting their Silent Switcher 3 parts. These aren’t quite right for my intended spec (won’t take a high enough input voltage) although otherwise very good. So my design is going to use a Silent Switcher 2 part – the LT8640S.

And I’m using Kicad 8.0 to design the board.

First Impressions of KiCad

I bought some books (two, KiCad Fundamentals and Projects and KiCad Advanced Projects and Recipes both by Peter Dalmaris (on offer from Elektor as a bundle !)

I did not read all 590 pages of the Fundamentals before starting !

I dipped and then got on with it.

My biggest problem with KiCad is that it isn’t Easy PC. When you have 20 years experience with some software anything else is bound to feel a bit weird.

The schematic editor isn’t too hard to get used to but I found the part chooser a bit of pain. I was able to find a symbol and footprint for the LT8640s (on SnapMagic) quite easily and rather less easily add it to the library. This later cause a bit of a problem but it was the symbol not KiCad which I think was wrong.

Anyway – it wasn’t that hard to get a schematic done.

Translating to a PCB and placing that was OK. This is an odd design in that some parts must be placed in just the right positions and linked with lots of vias to ground or with copper pours rather than tracks. High speed switchers just don’t work right if you ignore this.

It was quite slow going because I had to keep looking up how to do stuff - but that was to be expected.

The SnapMagic schematic symbol has all ground pins and the 4 little unconnected corner pins on top of each other. I thought this was a KiCad thing and was a bit disappointed by it but when I realised that all that was wrong was a whole load of ground pins being placed on top of each other in the schematic symbol I was soon able to edit it into something sensible. What I can’t understand is how any one could have thought that was a good idea - not all ground pins are the same – even though they may be linked inside the chip.

Back to the layout – KiCad was a bit easier that EasyPC at allowing me to add vias to the PCB footprint of the LT8640s.

I don’t like the manual routing - the software still keeps trying to coerce the track into silly shapes. This may be the way I have things set up and I shall experiment more before whinging. I like to route with a snap grid and without 90 or 45 degree constraints and then to adjust things the way I like. I might well break some clearance rules and move things later.

One snag that bit me was trying to set the outline of the TO3. The first problem was that KiCad calls the board outline the “EdgeCut” layer - logical enough but hard to find when you search for things like “outline”. I had to actually read the book a bit to find that one.

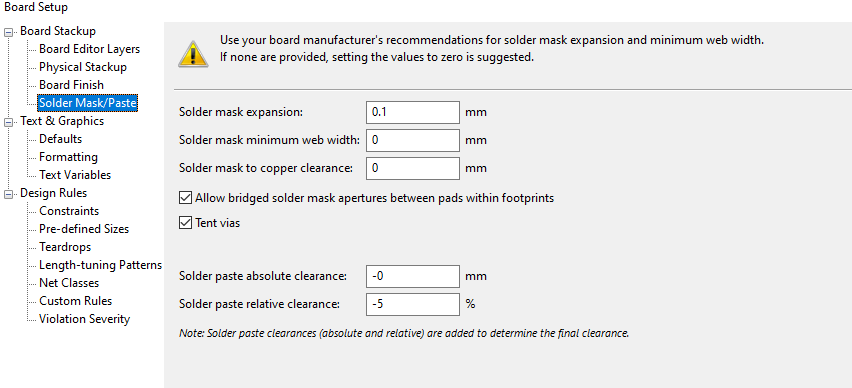

Then I hit a big snag – all the footprints from the library were making solder paste and solder mask apertures exactly the same size as the pad.

I spent the next two days on and off searching for a global way of setting a different default. I could easily change every pad on the board one at a time. I found several hits on the web that suggested that there is not global way to this and advised people to edit the PCB text file or write scripts. The index in the Dalmaris book is very week and while it does tell you in the book you won’t find it in the index.

Having done a good deal of cursing I returned to web searching and found what I needed. I’ll share it here in case it’s useful:

In PCB Editor click the Board Setup button.

Click Solder Mask/Paste under Board Stackup

Enter things for solder mask expansion and solder paste relative clearance.

So of course KiCad lets you set these things globally and its actually in a sensible enough place !

Now I could make the Gerber files and order the boards. It’ll be couple of weeks before they come back and I get bits on them and I can share some test results.

Conclusions

In conclusion – not too bad an experience. I’m not going to criticise because I haven’t used it enough to be sure that any problems I have are the software rather than me. But I didn’t hit any showstoppers. I think KiCad (on the basis of my limited experience) is a competent offering in the low - to mid performance sector of the PCB CAD market.

I still paid for this year’s maintenance upgrade for Easy PC !

Top Comments

-

genebren

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

genebren

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children