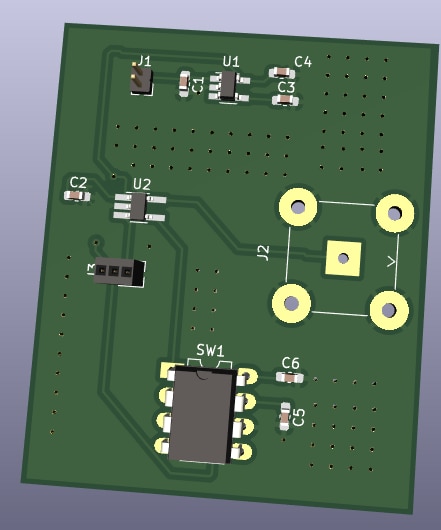

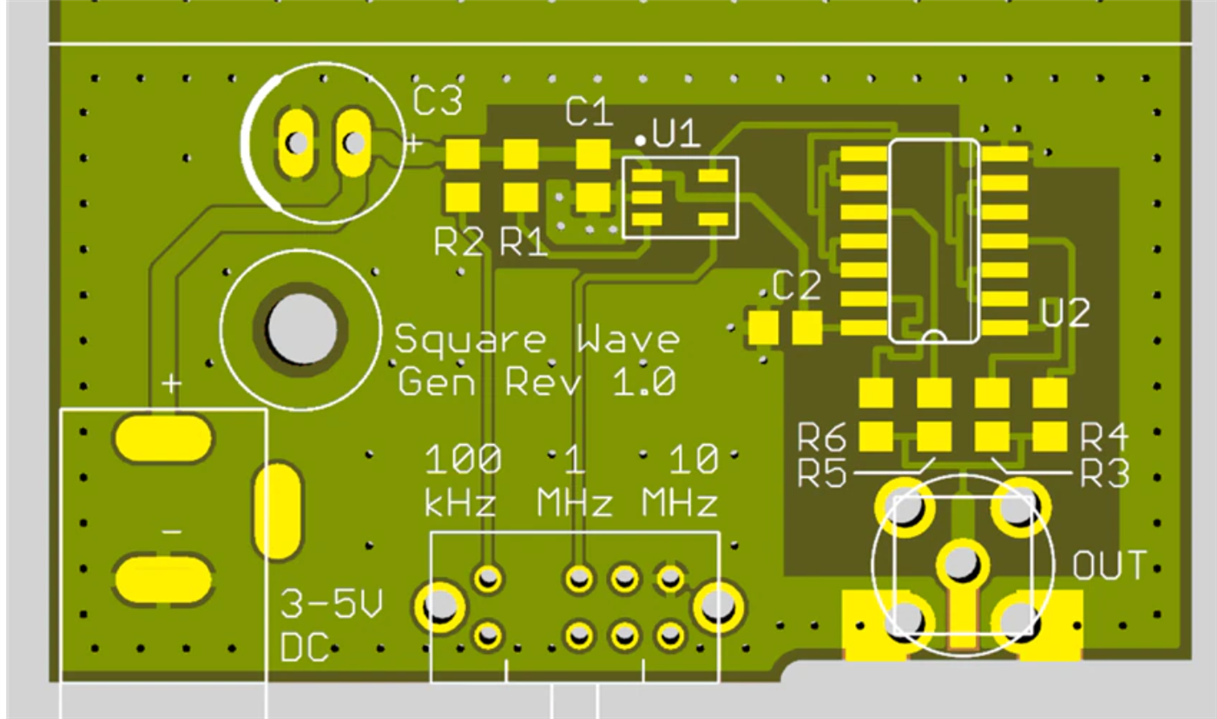

I'm working on an oscillator design using an off the shelf integrated circuit-based oscillator.

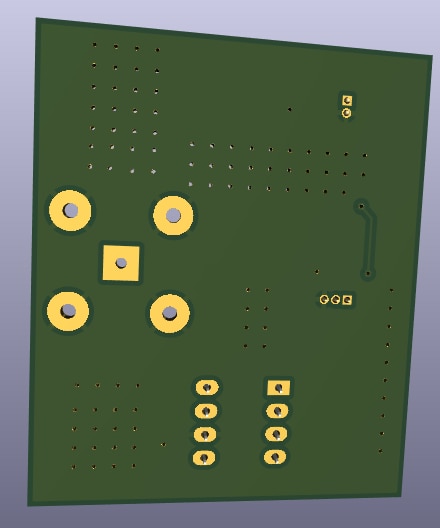

I have made two large gnd planes in the PCB, the top layer as well as the bottom layer.

Is this a good practice esp. for making PCBs for applications like oscillators?

I have also added plenty of vias to connect the two layers.

I just wanted suggestions (if any) before I send the PCB for fabrication.