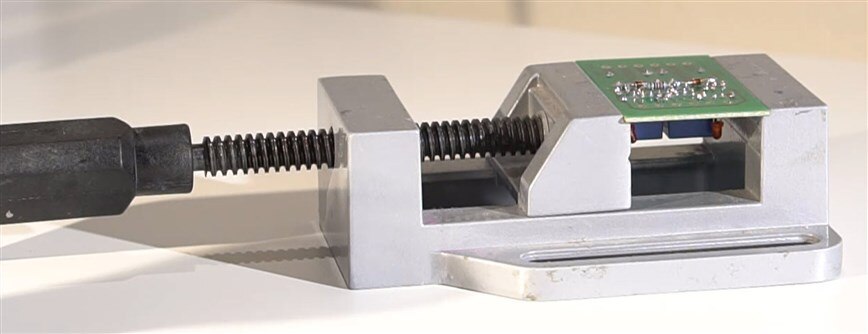

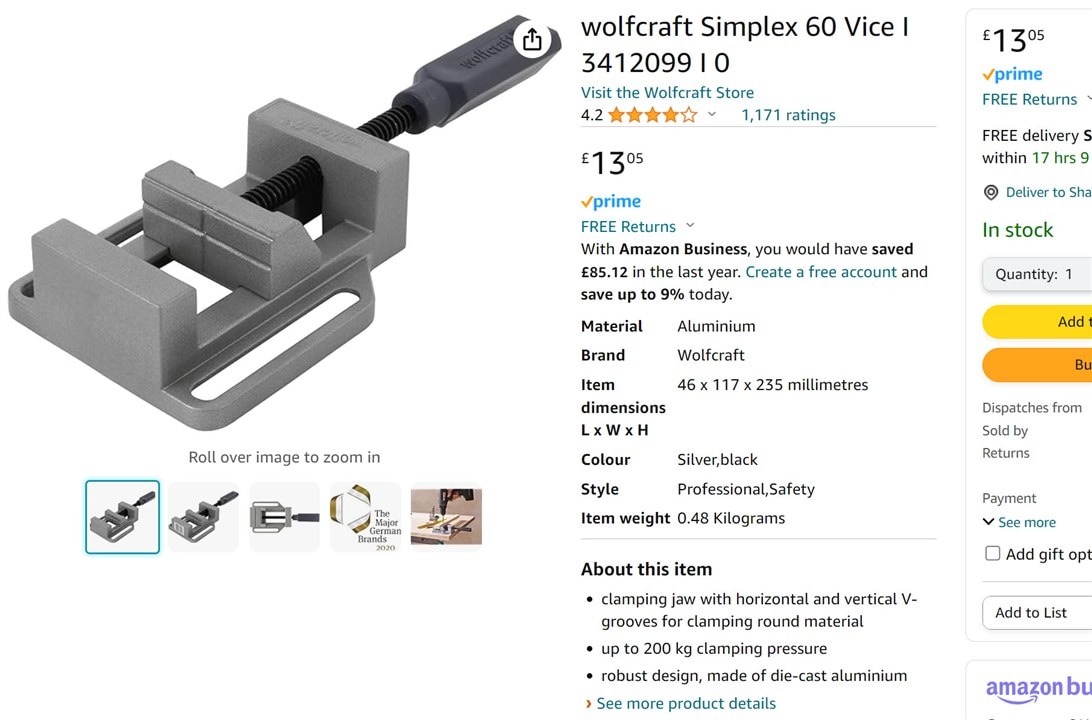

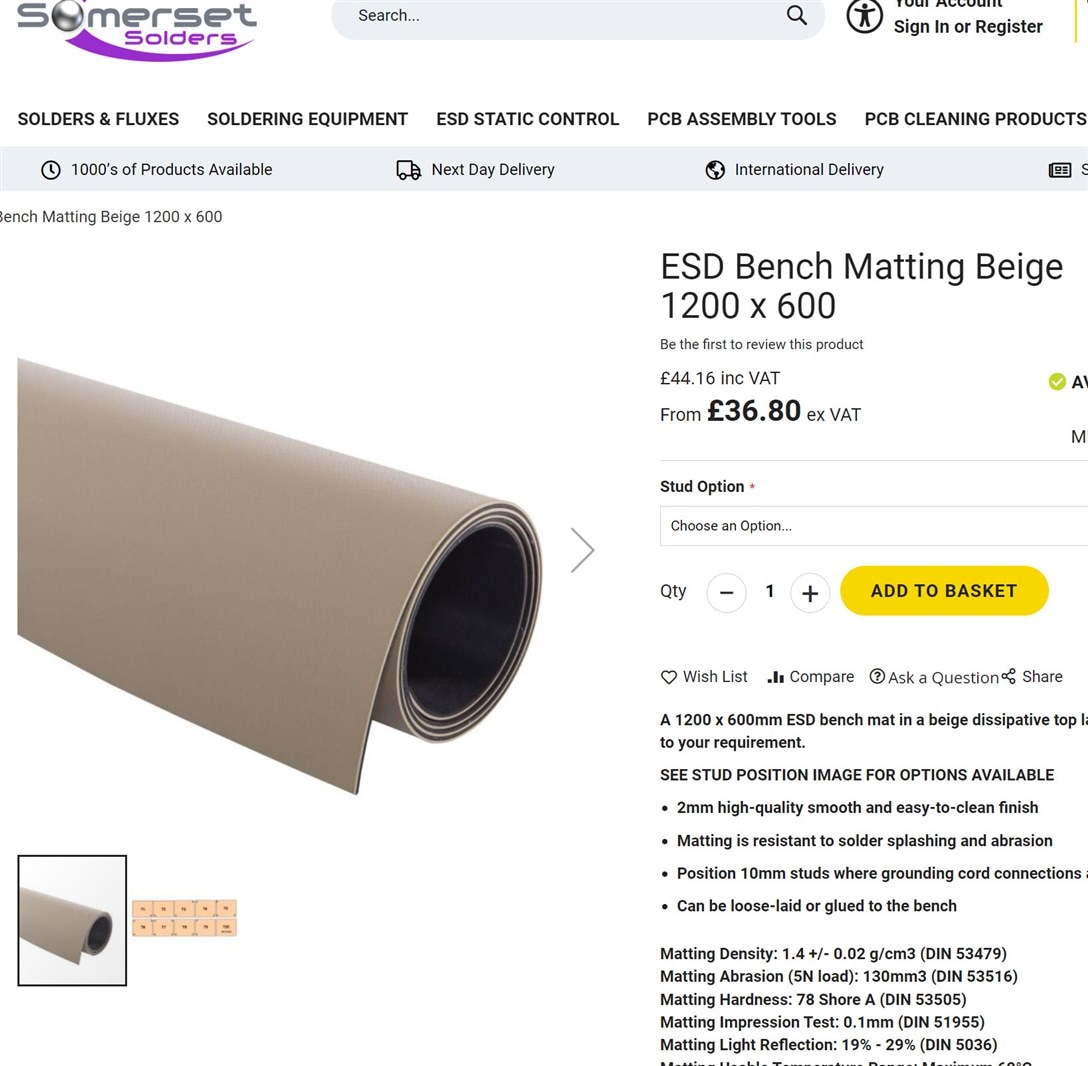

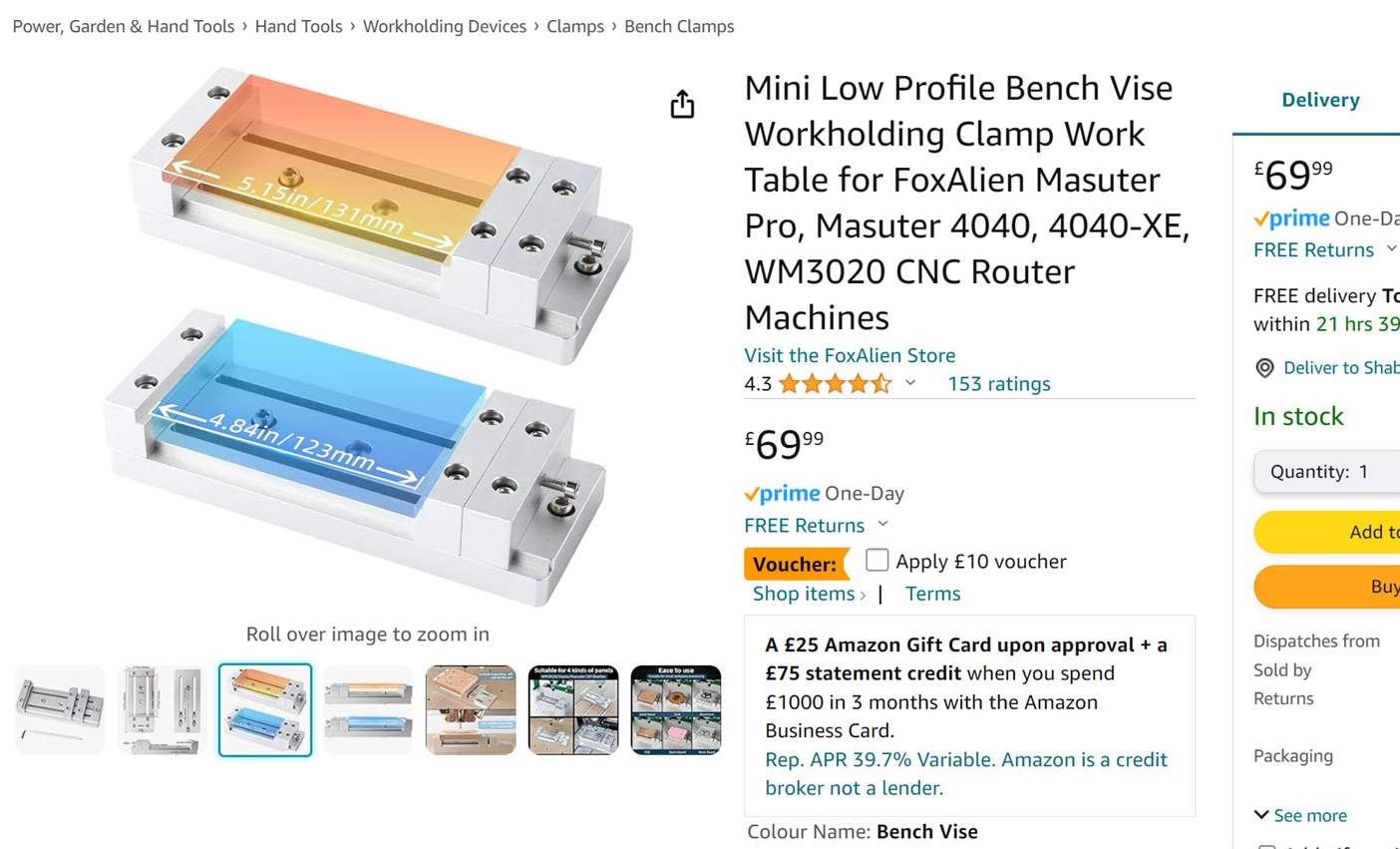

I've been doing some reorganizing and noticed I have a collection of PCB holders. I decided to do a quick post on them to spark some discussion around what constitutes a good PCB holder.

This video is a brief overview of the holders I have and how I use them.

What do you use to hold PCBs and what do you think is a good holder system?