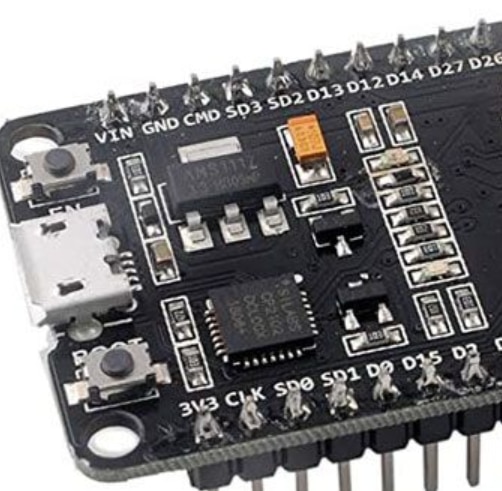

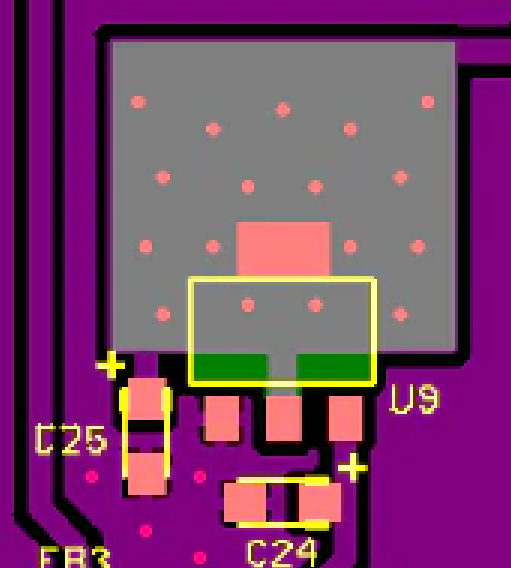

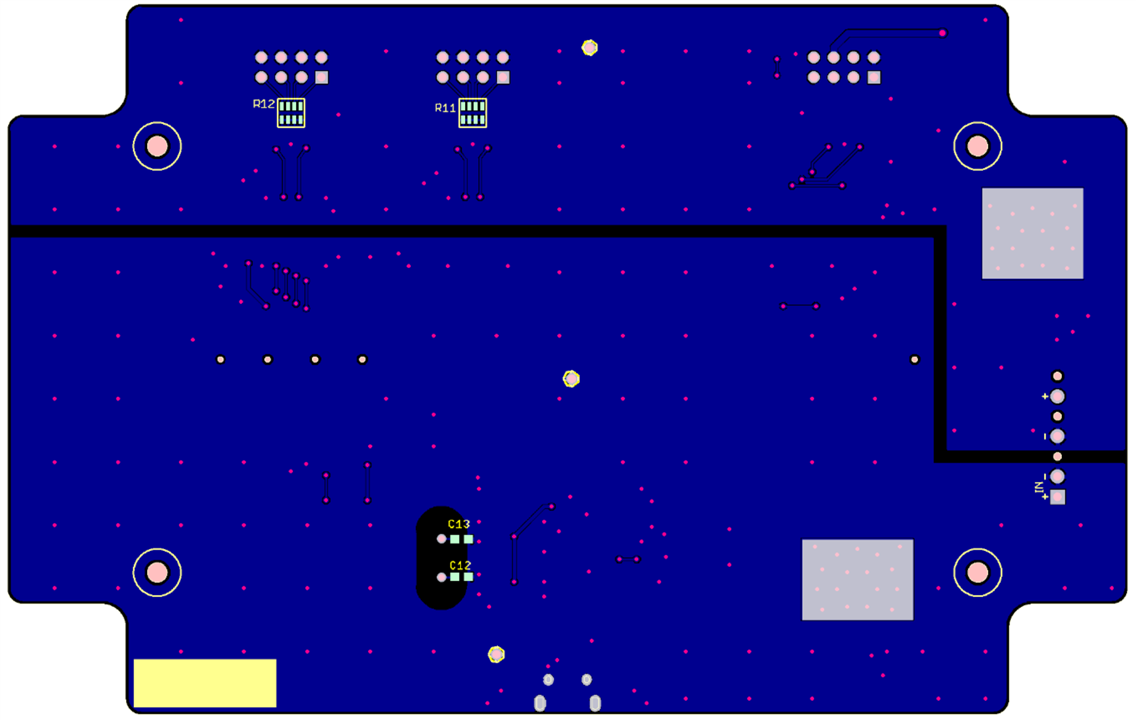

I guess I should have guessed what all that empty space on the original Raspberry Pi Pico board was for. They put a WiFi 802.11N chip there. CYW43439 from Infineon. This will be a nice board for IoT. And it's cheap. $6.

https://www.raspberrypi.com/news/raspberry-pi-pico-w-your-6-iot-platform/