Note: This is part 1 of a 2-part post. For part 2, click here: Raspberry Pi 3 Dynamic Current Consumption, Power and Temperature Tests

To see an implementation using a heat pipe, see the Outdoor Pi 3 Image Recognition Security Camera project (aka HAL-CAM 9001)

Inspired by Christopher's cstanton Raspberry Pi Operating Temperature report (with thermal photos from Gareth Halfacree) regarding the heat dissipated by the Broadcom chip on the Raspberry Pi 3, and the discussion with bwelsby we started searching around for ways to keep the Pi cool.

Ceramic heat sinks have an innovative structure (vias or micro-pores) which allow a heightened thermal conductivity compared to traditional aluminium heat sinks. They also can have the advantage that they won't affect radio frequency (RF) communications as much, when positioned close to the wireless antenna that is present on the Pi 3.

Furthermore, ceramic heat sinks are not electrically conductive and therefore there is no risk of accidentally shorting something on the Pi.

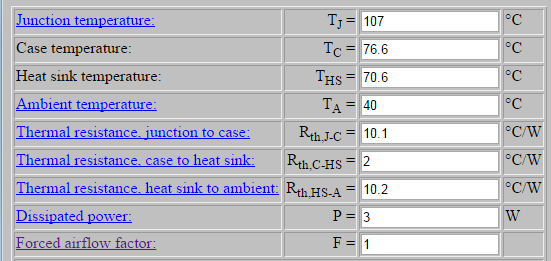

Back-of-the-envelope calculations (we don't have all parameters since we don't have a copy of the Broadcom datasheet to examine the device operating conditions in detail, nor a copy of the schematic to examine if we can measure device power consumption isolated from the remainder circuitry) suggests that a heat sink with thermal resistance of around 10 degrees C/W might be effective to keep the Broadcom chip's internal temperature below 120 degrees C when the ambient temperature is below around 40 degrees C. These are guesstimates until practical measurements have been taken.

Armed with this information, I searched for a suitable sized heat sink and I found a cheap aluminium one. However bwelsby and cstanton suggested that there may be issues with the heatsink getting in the way of connected HAT boards on top of the Pi, and Brian suggested examining ceramic heatsinks.

In summary, I think these parts may be suitable although measurements still need to be done:

22x22x2.5mm MPC222225T22x22x2.5mm MPC222225T

15x15x2.5mm MPC151525T15x15x2.5mm MPC151525T

(Optional) 20x20x10mm 5V DC fan MC33873(Optional) 20x20x10mm 5V DC fan MC33873

(EDIT: after some discussions below, it looks like this Sunon 'DR-MagLev' design fanSunon 'DR-MagLev' design fan is a far better choice, it is 25x25x10mm, quieter, higher throughput, and more efficient with overall lower power consumption. There is also a 25x25mm finger guard25x25mm finger guard).

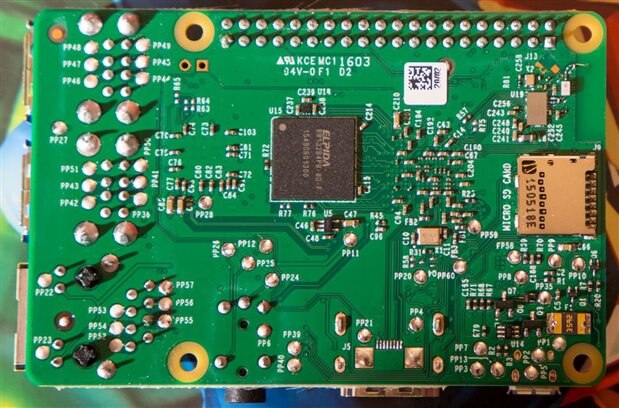

The Broadcom chip is about 14x14mm in size, and ceramic heat sinks do exist in approximately that size. However it is possible to attach a larger heat sink if desired.

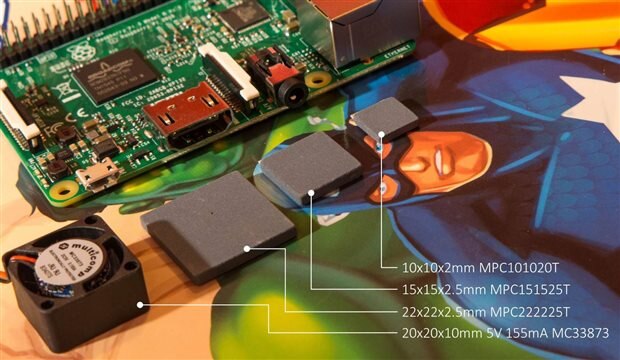

The photo below shows the parts that were examined. All of these ceramic heat sinks come with adhesive tape on the underside; the protective tape is removed and the heat sink will stick to the top of the integrated circuit.

The photo at the top of the blog post shows the largest 22x22mm ceramic heatsink.

The photo below shows a heat sink closer to the size of the Broadcom chip, 15x15mm. It also shows a 10x10mm heat sink on top of the USB hub/Ethernet controller chip, however this is really not needed. It doesn't get very hot according to the thermal photos in the previous blog post.

The memory chip on the underside gets hot too. If desired, the 15x15mm heat sink could be attached there too. The 22x22mm one is too large for that location due to nearby components (the memory chip has a lower height than the Broadcom chip on the top side).

So, I plan to attach a 22x22mm part to the Broadcom chip on the top of the board, and possibly a 15x15mm heat sink to the memory chip on the underside. I don't think a fan will be needed unless a very small enclosure with no natural ventilation was used, or if the Pi was in a very warm environment.

In that case, a fan may be an option. I tried the MC33873 fanMC33873 fan and it generates a usable level of air that can be felt from a distance of 10cm or more. However it does generate a small amount of noise too (possibly inaudible if the Pi will be behind other items such as a TV, but I think there is still a risk it could be audible. The voltage could be reduced from 5V to lessen the noise). It could be mounted on the heat sink as shown here although I think a small gap would be good to allow forced air to hit the entire top face of the heat sink. (The red dot on the fan was placed by me so that I could see it spinning). The fan could be secured with epoxy adhesive. The overall height is less than the height of the USB connectors on the Pi 3. The problem with this is that a HAT board cannot be plugged on top if there is a fan in the way.

A very nice solution would have been to put the fan on the side (to the left side of the photo above) so that the fan could blast air across the entire top face, and the underside of the board. However the display connector (the long white thing on the edge of the board in the photo above) is in the way and would block the flow of air which is extremely unfortunate. The Pi 3 wasn't designed with air flow in mind : ( However it might be possible with some 3D-printed duct design to achieve something that could work.

To summarize, some heat sinking ideas have been suggested however it is for further examination to see how well they perform. It will be good to see what solutions people come up with over time.

Top Comments

-

shabaz

-

Cancel

-

Vote Up

+4

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

bwelsby

in reply to shabaz

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

shabaz

in reply to bwelsby

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

bwelsby

in reply to shabaz

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

cstanton

in reply to bwelsby

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

bwelsby

in reply to cstanton

-

Cancel

-

Vote Up

+1

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

shabaz

in reply to cstanton

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

shabaz

in reply to cstanton

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children