RoadTest: Panasonic Laser PM2.5 (Dust/Smoke) Sensor w/ MCU - Industrial Sensing

Author: BigG

Creation date:

Evaluation Type: Independent Products

Did you receive all parts the manufacturer stated would be included in the package?: True

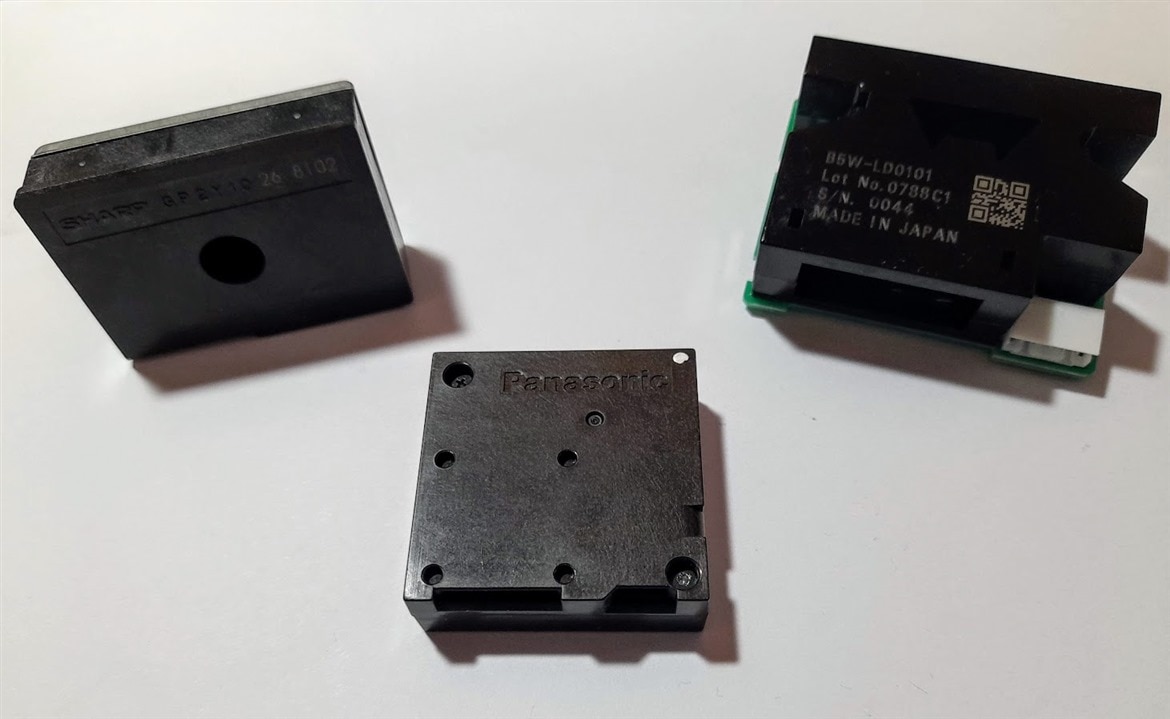

What other parts do you consider comparable to this product?: The Sensirion SPS30 PM2.5 sensor, or the Sharp Dust Sensor Units (e.g. GP2Y1026AU0F with UART output or GP2Y1010AU0F with analog output) or the B5W-LD0101 Air Quality Sensor from Omron.

What were the biggest problems encountered?: Cable connector was not readily available and mounting the product onto a surface.

Detailed Review:

The SN-GCJA5 particulate matter sensor from Panasonic Industries uses a laser diode instead of a light emitting diode (LED) to more reliably detect the quantities of PM2.5, PM10 & PM1 sized particles within the enclosure’s detection zone. A micro-fan is used to generate air flow and a microprocessor is then used to analyse the particulate matter counts based on a predefined algorithm to calculate particulate matter densities and this data is then transmitted via UART and I2C communication protocols.

The features and benefits of this sensor, as listed on the Panasonic North American website’s product page are as follows:

In addition to the above, the main Panasonic website also lists the auto calibration function as a feature.

I was not able to validate any of these claims other than the first one. It really was much easier to obtain measurement data than the other two sensors I tested as a comparison (see below).

What's not listed was that the sensor also provides a status function to indicate to the user if a fault has been detected. I thought this was a very useful feature.

The sensor does not come with demo software, hence the score given for "Demo Software was of good quality" category is NA (Not Applicable).

For this roadtest I reviewed how quickly it took me to get up to speed and develop an application using the documentation provided.

As I don’t have any calibration instruments to validate readings I also made comparative observations based on two other dust sensors I’ve used in the past, namely the Sharp GP2Y1026AU0F and the G5W-LD0101 from Omron.

Then by way of demonstration, I created three blogs explaining what could be done. The first two blogs were getting started guides demonstrating how easy it was to get started using UART and I2C with a Raspberry Pi Pico board and the Arduino IDE.

The third blog described how to build a BLE application using both the SN-GCJA5 particulate matter sensor and the B5W-LD01 from Omron.

A further demonstration using the Sharp GP2Y1026AU0F sensor with the SN-GCJA5 sensor will be provided in another blog for Arduino (I used the Arduino MKR1000 as the MCU).

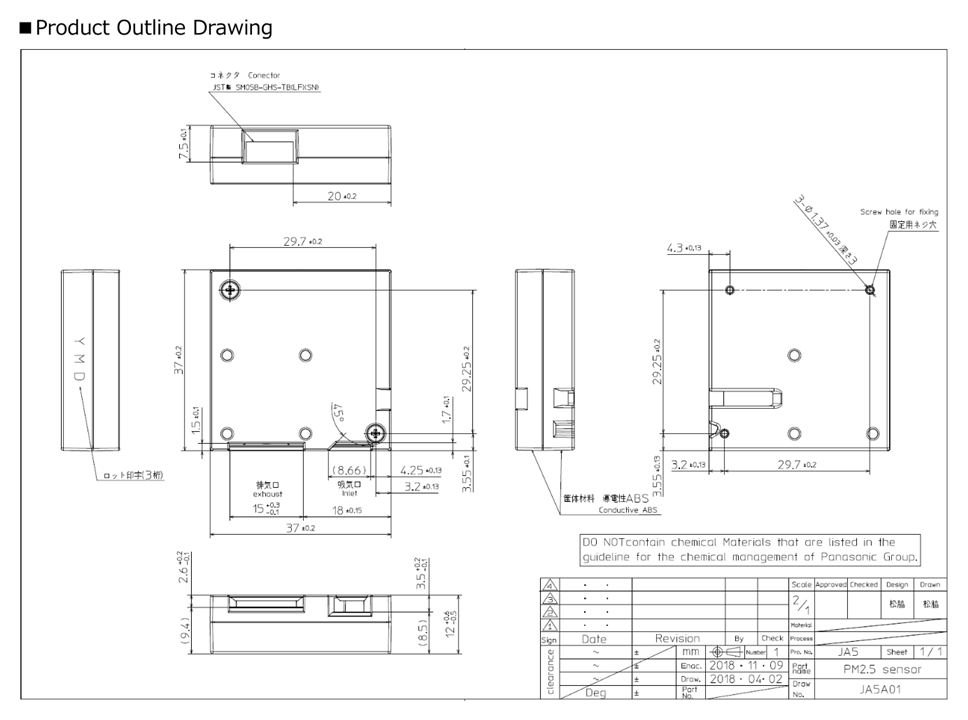

The SN-GCJA5 square enclosure is a mere 37mm x 37mm and is only 12mm thick, making it the smallest PM sensor enclosure I’ve ever come across.

However, this enclosure appears to be missing mounting holes. It was not immediately apparent as to how one fixes the enclosure in place. The above diagram indicates 3 screw holes for fixing but two of those already have screws on the underside keeping the two parts of the enclosure together. The sensor documentation instructs the user not to remove those two screws. I did not attempt to use the 3rd screw hole in case it damaged the sensor.

By way of comparison, the larger Omron B5W-LD01 sensor does include mounting holes while the Sharp GP2Y1026 sensor did not, although it did have a ledge to hold it in place.

| {gallery:autoplay=false}Mounting holes |

|---|

|

B5W-LD0101: Mounting holes |

|

Sharp GP2Y10 sensor: surface ledge to keep sensor in place |

The managed air flow through the SN-GCJA5 sensor is via a separated inlet and outlet port on the underside of the sensor when mounted vertically (see above diagram for location of each). The Omron B5W-LD01 sensor also has an inlet port on the underside of the sensor but the outlet is on the side of the sensor. The Sharp GP2Y1026 has a circular hole through the middle of the sensor.

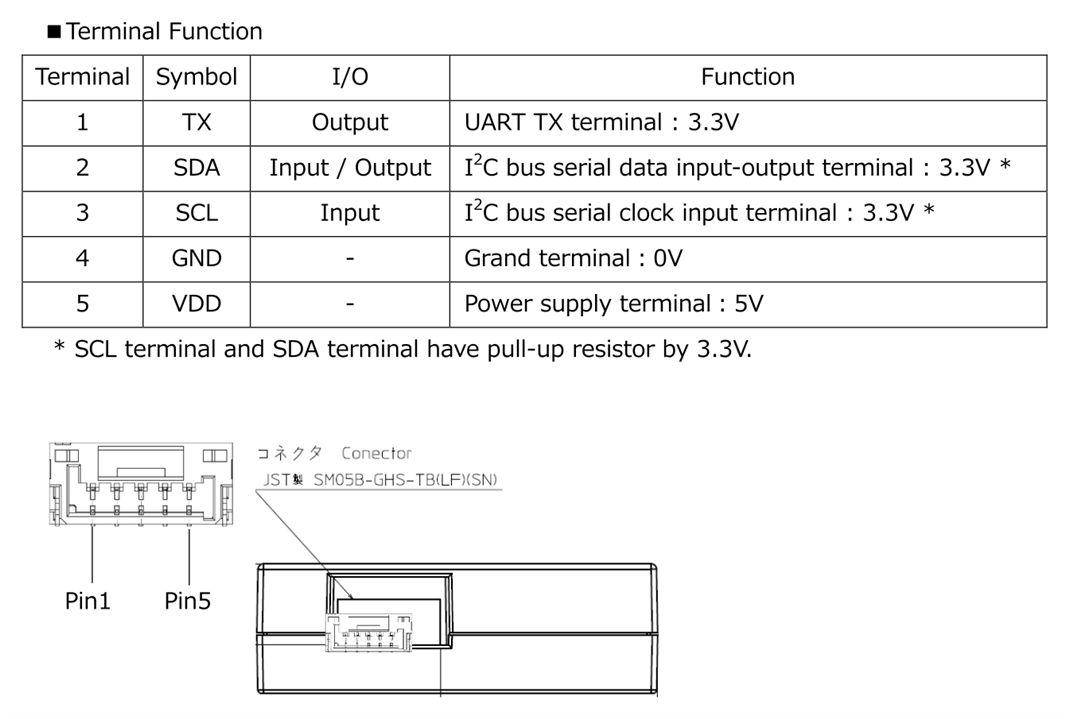

The connector used on the SN-GCJA5 sensor is a 5-pin JST (SM05B-GHS-TB) Wire-to-Board type connector with a 1.25mm pitch. As we all discovered, getting hold of a cable harness with this connector is hard to find at the moment as frequently distributors are temporarily out of stock.

This sensor is not the only one with a unique connector. The Sharp GP2Y sensor uses a 6-pin, 1.5mm pitch JCTC connector (11501W90-6P-S-HF) and the Omron B5W-LD01 sensor uses a 5 pin, 2mm pitch TE connector (AMP 292164-5).

The difference though is that with these two other sensors, it is easy to hack on your connector if you could not get hold of a suitable connector.

| {gallery:autoplay=false}Sensor Connectors |

|---|

|

SN-GCJA2: Connector inserted within enclosure |

|

Omron B5W-LD0101: 2.54mm header pins soldered onto test points |

|

Sharp GP2Y1026: attached a 4-pin Grove connector on top for UART |

The technical details of the sensor hardware is provided within the Panasonic SN-GCJA5 spec sheet: JA5-SSP-E20_Product-Specifications_e.pdf

As a summary here is a comparison of the key parameters against other sensors.

|

Panasonic SN-GCJA5 |

Sharp GP2Y1026 |

Omron B5W-LD01 |

Sensirion SGP30 |

|

|

Light emitting element |

Laser diode |

LED |

LED |

Laser diode |

|

Min. detectable dust size |

0.3μm |

0.5μm |

0.5μm |

0.3μm |

|

Dust density sensing range |

0 to 2000 μg/m³ (UART) |

0 to 1000 μg/m³ |

0 to 1000 μg/m³ |

0 to 1000 μg/m³ |

|

Sensing time |

1 second |

1 second |

> 1 second |

1 second |

|

Sensitivity / Accuracy |

Consistency ±10% |

0.35V ± 0.06V per 100 μg/m3 change Accuracy ±15% |

±1.25μg/m³per year (<100μg/m³) |

|

|

Sensing of separate PM sizes |

PM1.0 PM2.5 PM10 |

Total dust density only |

PM1.0 PM2.5 |

PM1.0 PM2.5 PM4 PM10 |

|

Interface |

I2C UART |

UART Analog (other GP2Y models)> |

Pulse Count |

I2C UART |

|

VCC |

5V |

5V |

5V |

5V |

|

Supply Current |

<100mA |

<20mA |

90mA |

<80mA Has sleep mode |

|

Operating Temperature |

-10 ~ 60°C, under 95%RH |

-10 ~ 65°C, under 95%RH |

0 ~ 45°C |

-10 ~ 60°C, under 95%RH |

|

Package Size |

37 x 37 x 12 mm³ |

46 x 30 x 18 mm³ |

50 x 40 x 18 mm³ |

41 x 41 x 12 mm³ |

|

Product mass |

13g |

17g |

? |

26g |

|

Lifetime |

+5 years |

? |

? |

10 years |

The I2C and UART data transfer protocols are described in the document: JA5-SSP-COMM-E14_Communication-Spec_e.pdf

I had no problems with this document.

Please refer to my getting started blogs on how to implement using Arduino.

I created two wireless remote monitoring applications as part of my review.

The first was a BLE based application where I used both the I2C data transfer protocol for the Panasonic SN-GCJA5 sensor and pulse counting for the Omron sensor.

The second was a WiFi based application where I used the UART data transfer protocol with both the Panasonic SN-GCJA5 sensor and the Sharp GP2Y1026 sensor. The details of this application will be provided in another blog for Arduino (TBC).

I found the Panasonic SN-GCJA5 sensor very easy to use and liked the fact that it provided both Particulate Matter (ug/m3) data and Particulate Matter counts for different particle sizes. I also found the status indication to be particularly useful.

The only downside was getting access to the pin connector, if you needed a workaround, and the lack of clearly marked mounting holes.

Finally, I would also like to thank Element14 and the suppliers Panasonic Industries for the opportunity and for the extension to complete my road test.

I trust you found my review informative and if you have any comments please leave those below. Thank you.