I am trying to design a circuit for a new sensor board which essentially uses UART comms but I want to incorporate the option for USB to allow you to use a USB cable from a Raspberry Pi USB host to the sensor board.

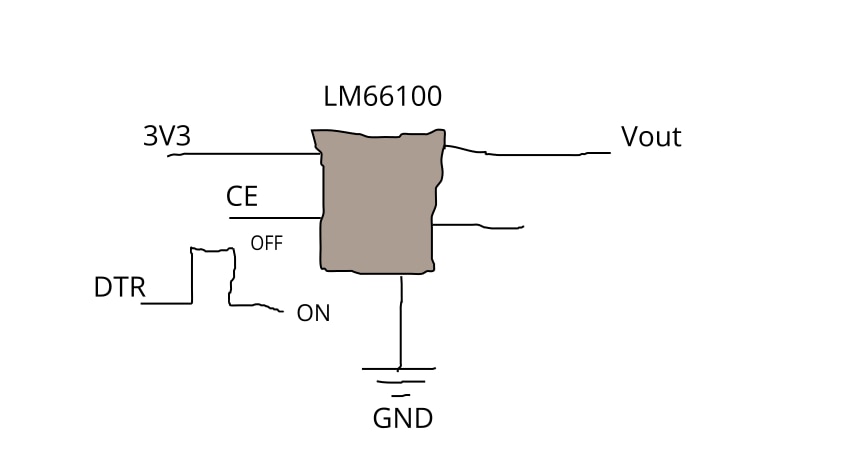

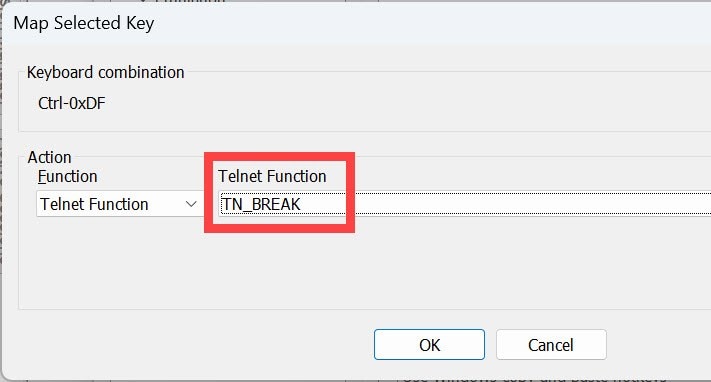

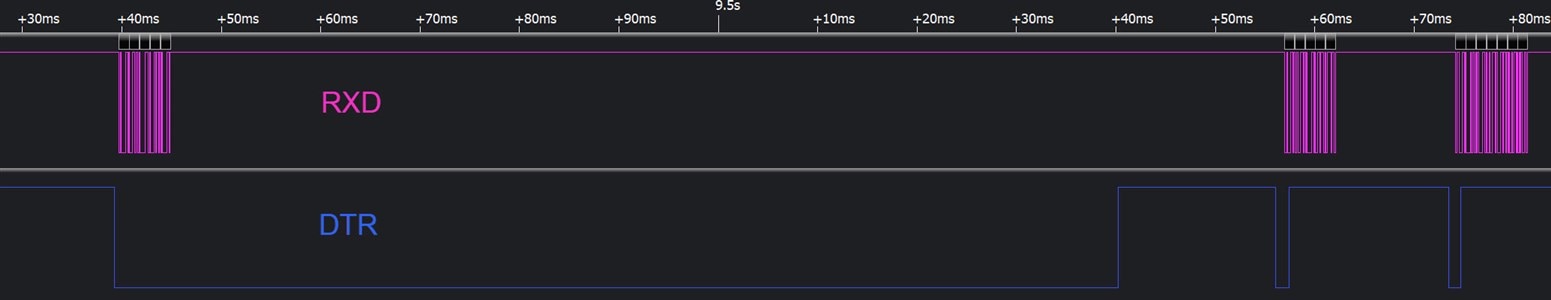

But if I'm using USB I don't have access to the Raspberry Pi's reset pin via the USB cable. This is no problem if the Raspberry Pi powers up, but that is no good if the Raspberry Pi reboots. I would like to have it that if the Raspberry Pi reboots, my sensor board will do so too.

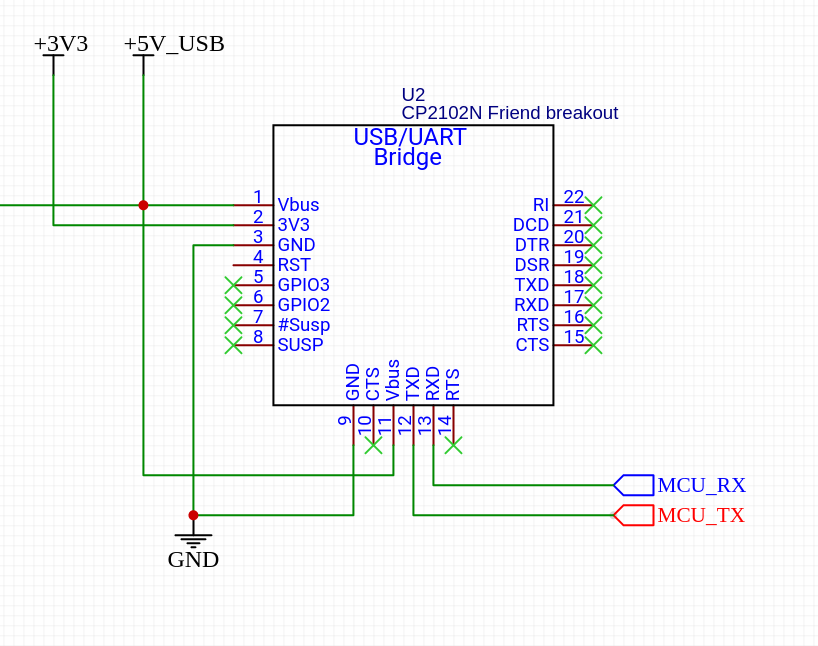

To simplify the design and testing process I am using one of these breakout boards: www.adafruit.com/.../5335

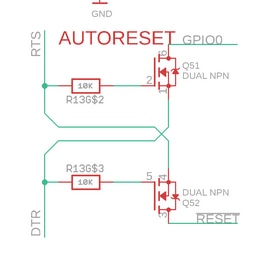

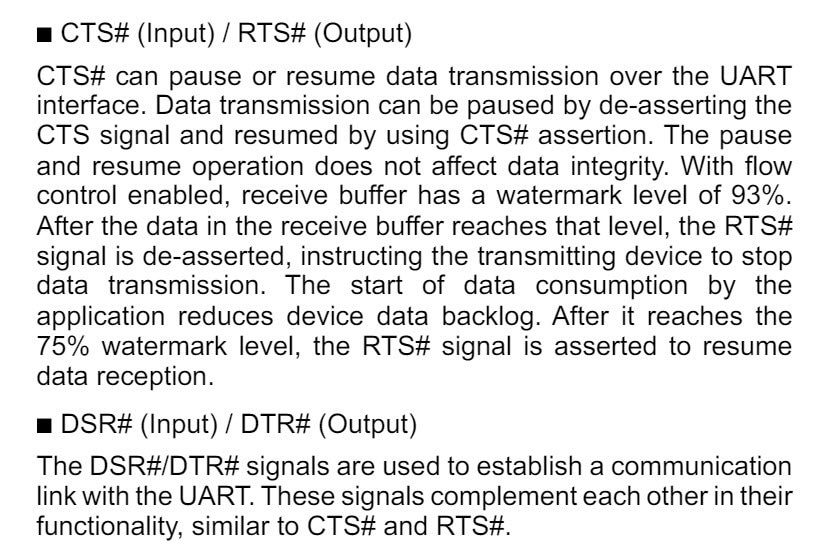

This uses a CP2102N and breaks out DTR, RTS, CTS etc etc. So I have options.

But I don't have any ideas... hence the question