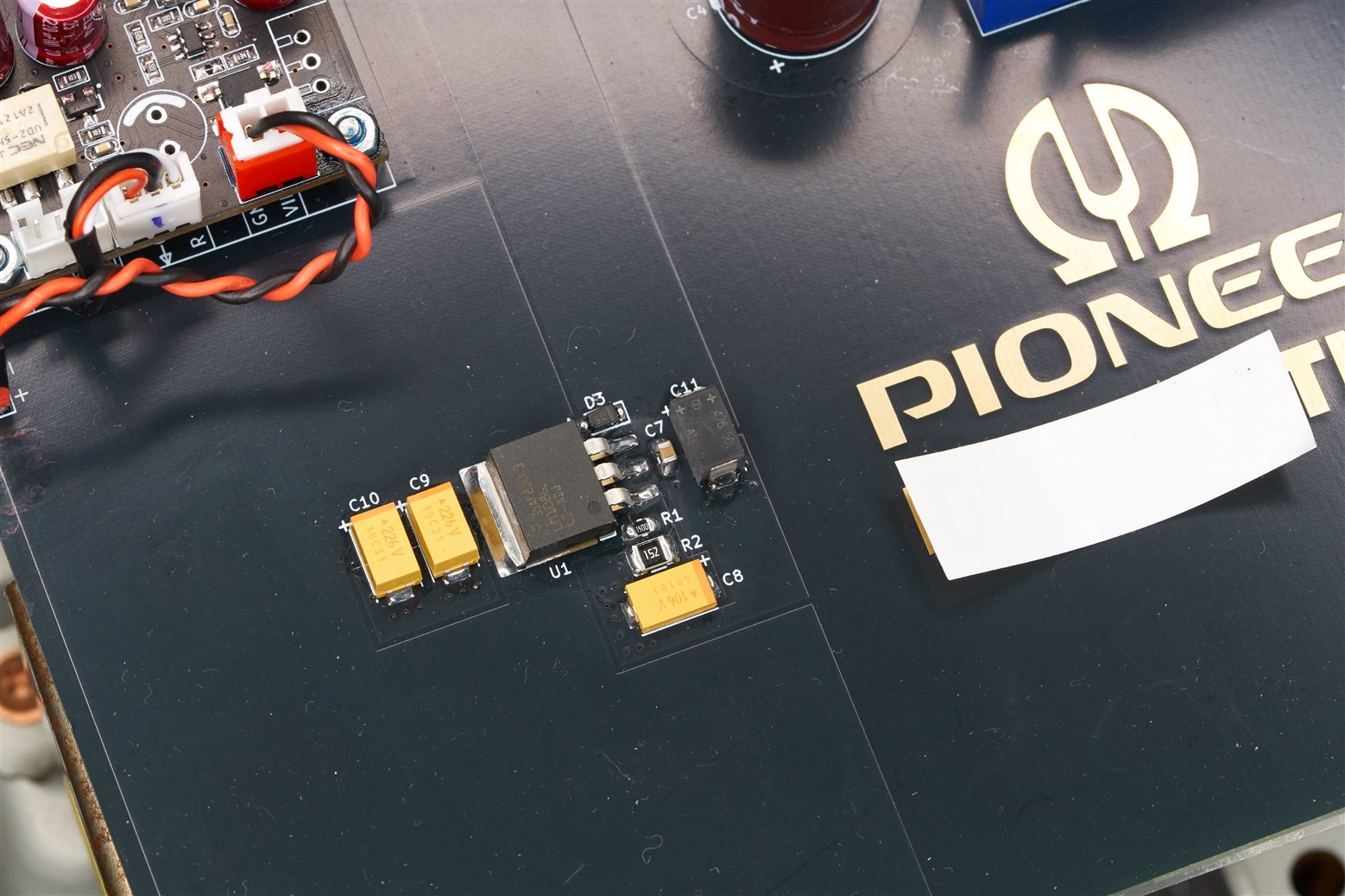

I received a new TV box from the cable provider They suggested to drop the old one at an electronics recycle collector. That didn't happen - I opened it up. I've put the internal hard drive for sale on a 2nd hand site. For the other components, I'm checking what (if anything) is worth keeping.

What caught the attention, is that one of the electrolytical caps is beyond end-of-life. It's definitely bulging: It's the first time that I see one where the symptom is so obvious. I had others that failed or leaked. But never such a visible sign of the internal pressure effects.

Can you spot the culprit?

Title inspiration: capacitor labs.