I purchased a very small (less than A4 paper sized footprint!) table saw called Proxxon KS 230 , and it arrived today. It's not my first Proxxon tool: Proxxon Rotary Tools Review: Micromot 50/EF, FBS 12/EF and NG 2/E

The KS 230 comes in a box not much dissimilar in size to a couple of reams of printer paper.

I have other cutting methods, but I deliberately wanted something compact for small woodworking and the occasional metalwork. The KS 230 is designed for up to 8 mm thick wood, or 3 mm plastic (which is the most popular thickness of plastic that I work with) or for metals (excluding steel and iron) up to 1.5 mm.

The KS 230 is intended to (possibly temporarily but I’m waiting to try the KS 230 out first – and see my comments later!) replace my older table saw, which is the Bohler Minitool 320 305. It must be at least 20 years old; I’ve had it at least 10 years, and I purchased it second-hand. It’s always been slightly underpowered. Recently, the saw blade has started to stall when slightly too much pressure is applied. I don’t know if the toothed belt needs replacement, it doesn’t look in best condition.

You’re supposed to attach a dust extractor to the table saw, and if you don’t, this is the result; probably an extreme fire hazard too when all the dust sits inside.

Anyway, back to the KS 230:

It came with grease on the top surface. Not sure why, since it’s plastic and aluminium. Maybe the supplier did this to protect it in storage. I wasn’t too happy that the mains plug had scuffed the metal, but it’s a minor thing.

The KS 230 has a saw cover visible in the photo below; it’s non-removable, and just lifts and hinges up while you’re sawing. You’re supposed to resist the temptation of ripping it off, because the metal thing it is attached to is supposed to keep the material that you’re cutting straight, because table saws are quite dangerous (the material can grab on the saw blade and propel precisely in the direction of the operator).

Here are all the supplied accessories. The angle guide stinks, it is made of plastic with the metal bar secured with one screw. You will need a square (unsupplied of course) to set it to precisely 90 degrees.

I have other Proxxon tools, and I wish they would do something about their angle guides, those are always poor quality.

I might machine up my own all-metal angle guides for say 90 and 45 degrees one day.

The photo below shows the guides installed as they would be used. Incidentally, that hole next to the saw blade is used with a supplied 2 mm hex key, to hold the shaft locked, while replacing saw blades.

The photo below shows the power switch, and to the right of it, one of the two holes that can be used to screw the table saw to a surface (I won’t be doing that).

The deep recess in the plastic top surface, on the left-hand-side, serves a purpose not currently known to mankind. No supplied accessory fits it.

You can see the dust extractor port in the photo below.

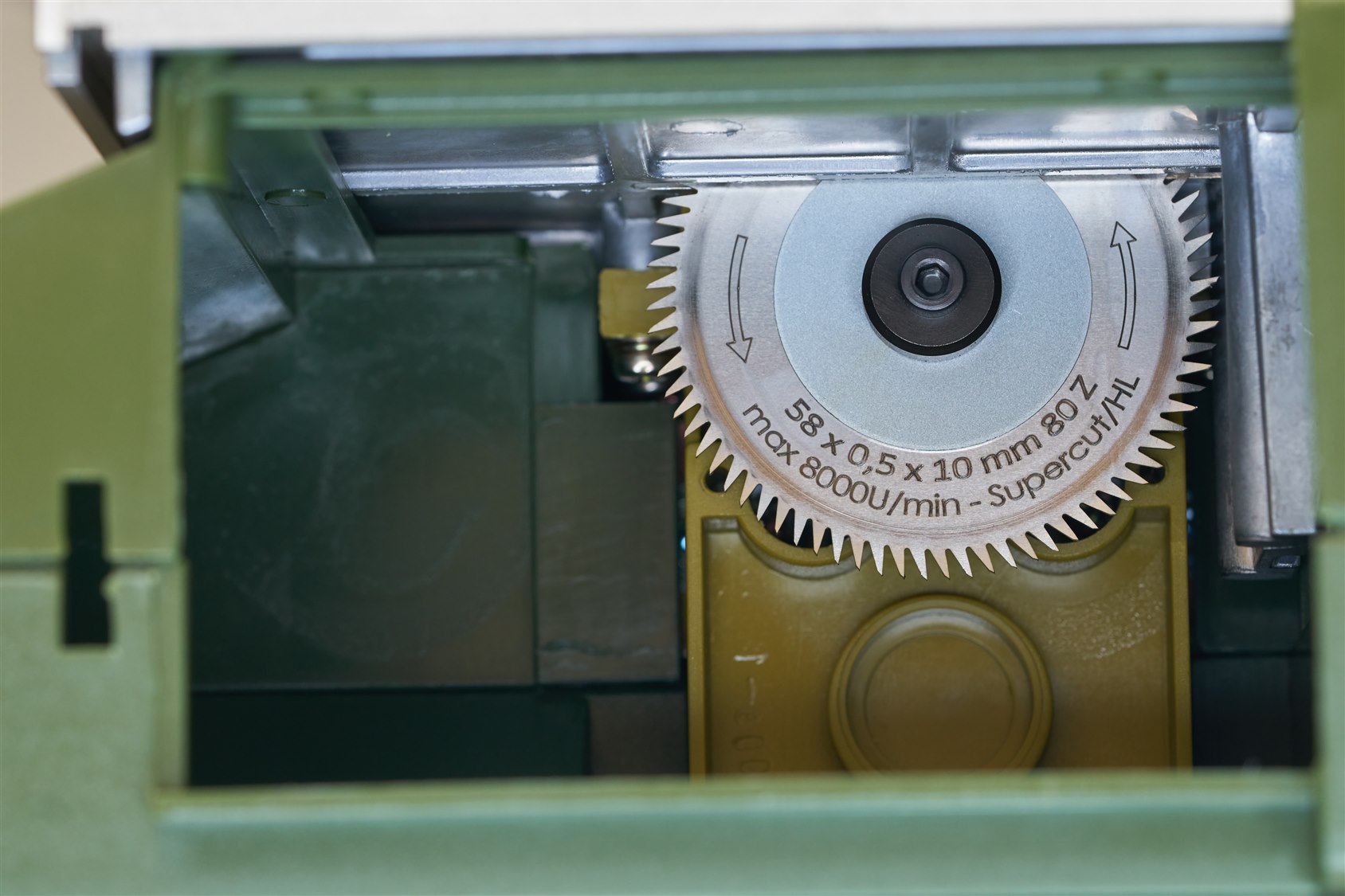

The side of the unit has a removable 3 mm hex driver, which is used to unscrew the saw blade, by first unscrewing the side cover, which is held in place with a captive hex cap screw latch.

With that side cover removed, you have access to the saw blade so that it can be swapped out.

No additional saw blades are supplied, but I purchased the following ones, intended for (from left to right) balsa/plywood, wood/plastics, and alu/brass/copper.

I’ve yet to use the tool, but at first impressions, it seems of OK construction for the price, apart from that stinky angle guide. It wouldn't have hurt the manufacturer to stick a 'push guide' (i.e. something you can prod the material that you're cutting with, to push it toward the saw blade) in the box, and perhaps a cheap square, to align that angle guide.

One thing I’m extremely unimpressed with, is that there’s no way to angle the blade, nor any way to raise or lower the blade. Seems quite a loss of functionality compared to the older Bohler tool, which supports all this. I'm glad I still have the Bohler tool (which doesn't seem to be manufactured any more, but maybe I'm mistaken) to repair one day, if I find the Proxxon tool's lack of functionality to become too much of an irritation.

Overall, at first impressions, I’d rate this product 6.5 out of 10, good from far, but far from good. There’s just not a lot of options at this price point, for a compact table saw for precise cuts. Do you think I'm being too picky and over-critical? Let me know.

Thanks for reading.

Top Comments

-

genebren

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

shabaz

in reply to genebren

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

genebren

in reply to shabaz

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

shabaz

in reply to genebren

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

dang74

in reply to genebren

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

shabaz

in reply to dang74

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

dang74

in reply to shabaz

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

dang74

in reply to shabaz

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children