|

For the Sound and Vibration Measurement Hat for Raspberry Pi road test, I reviewed industrial Piezo Acceleration Sensor PCB Piezotronics 603C01. It's intended for unfriendly environments, and has built-in electronics.

image / video source for all content in this blog: me |

This is a collection of comments made on other articles on element14. I'm bringing them together here, and try to put some structure in them.

Problem Statement: a Piezo disk generates high voltages

A piezo element can generate real high voltages. It's the device that generates the ignition spark in gas lighters, stoves, ...). Not good for your inputs.

I purchased a kit from the internet, with a protection circuit. Advertised as: "for the Raspberry Pi". here's how the signal at the output of that kit looks like, when the Piezo is agitated (ticked with a plastic pen):

Still not good for your inputs. A better design is needed, both to buffer the actual piezo signal, and to crowbar the high voltages in a better way.

Charge Amplifiers for Piezo Electric Accelerometers

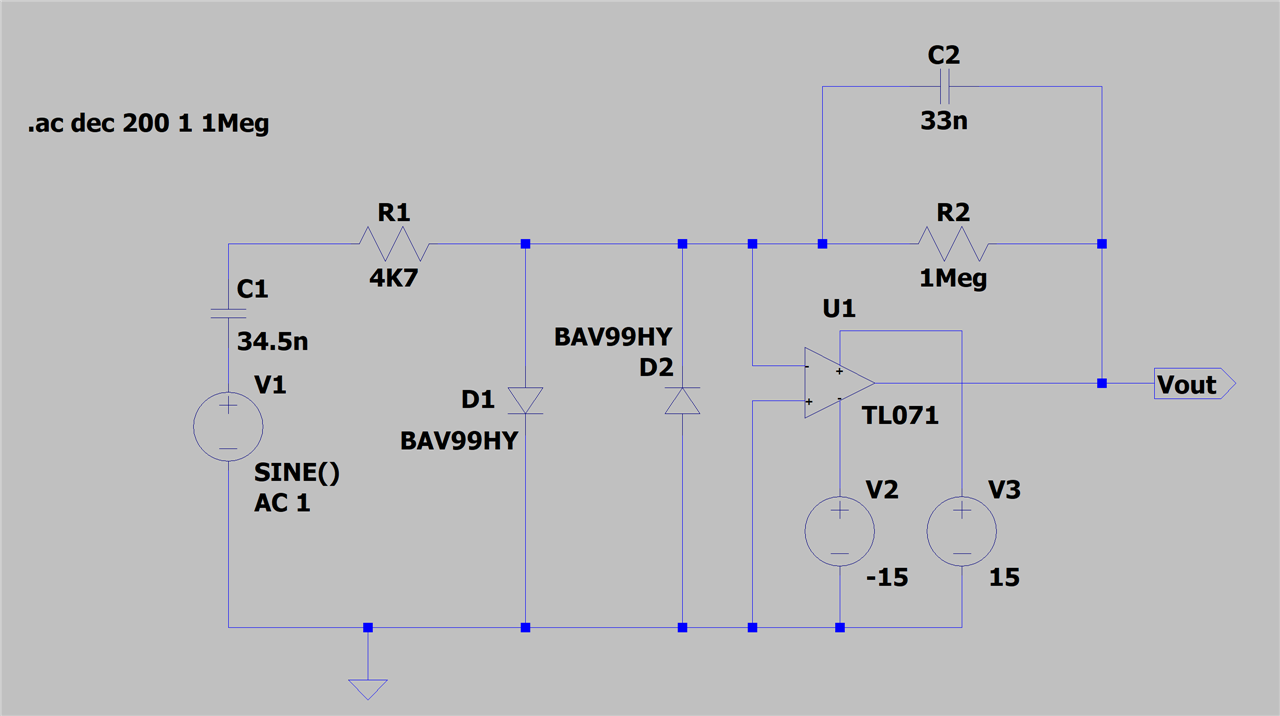

Michael designed a circuit that does both activities, and wrote a white paper about it. You can clearly see the two parts. Protection left, buffer right:

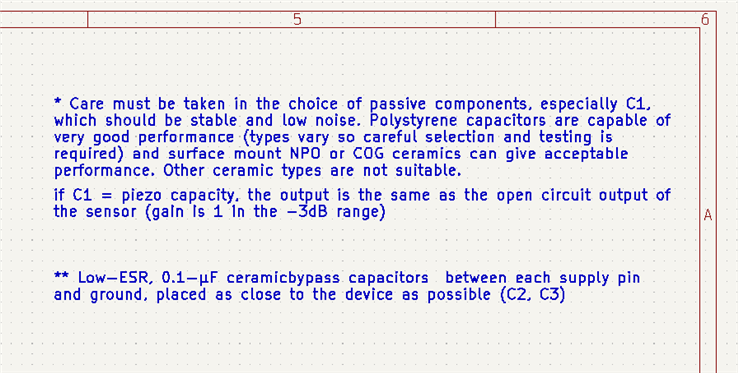

Two fast diodes keep the input under control, The buffer is a charge amp. To get 0dB (no gain), the capacitor in the feedback circuit should match the piezo element's capacity.

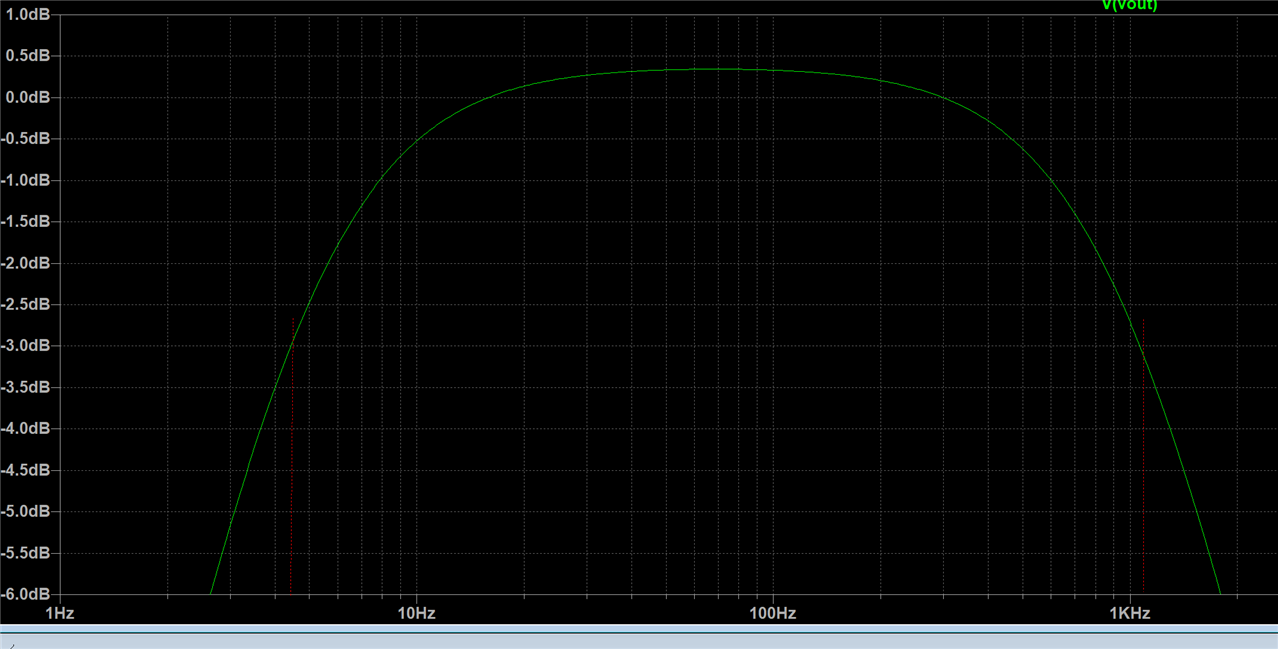

Simulation

LTSpice shows the amp's behaviour. The piezo element is replaced by a capacitor of the same value the piezo disk has (35 nF in my case, and an AC generator in serial.

Result:

I did not simulate the crowbar function and high voltage input behaviour, but that's possible too.

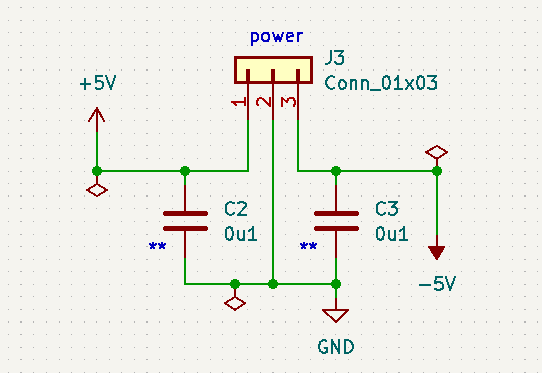

Building the Circuit

I designed a small PCB for this, in KiCAD. The main circuit is posted earlier in the blog. Here's additional circuitry, comments and the PCB design:

BOM:

| Vendor | Vendor # | type | qty | package | mf | mf code | description | url |

| farnell | 3416403 | C | 1 | 1206 | TDK | CGA5F2C0G1H333J085AA | SMD Multilayer Ceramic Capacitor, 0.033 µF, 50 V, 1206 [3216 Metric], ± 5%, C0G / NP0, CGA | https://be.farnell.com/tdk/cga5f2c0g1h333j085aa/cap-aec-q200-0-033uf-50v-mlcc/dp/3416403?st=33nf%201206 |

| farnell | 1907339 | C | 2 | 1206 | TDK | C3216X7R2E104K160AA | SMD Multilayer Ceramic Capacitor, 0.1 µF, 250 V, 1206 [3216 Metric], ± 10%, X7R, C | https://be.farnell.com/tdk/c3216x7r2e104k160aa/cap-0-1-f-250v-10-x7r-1206/dp/1907339?st=c3216x7r2e104k160aa |

| farnell | 2918843 | D | 1 | SOT-23 | ROHM | BAV99HMT116 | Small Signal Diode, Dual Series, 80 V, 125 mA, 1.25 V, 4 ns, 4 A | https://be.farnell.com/rohm/bav99hmt116/diode-small-signal-0-125a-80v/dp/2918843?st=bav99hm |

| farnell | 2447523 | R | 1 | 1206 | MULTICOMP PRO | MCWR12X4701FTL | SMD Chip Resistor, 4.7 kohm, ± 1%, 250 mW, 1206 [3216 Metric], Thick Film, General Purpose | https://be.farnell.com/multicomp/mcwr12x4701ftl/res-4k7-1-0-25w-1206-thick-film/dp/2447523?st=4k7%201206 |

| farnell | 2447478 | R | 1 | 1206 | MULTICOMP PRO | MCWR12X1004FTL | SMD Chip Resistor, 1 Mohm, ± 1%, 250 mW, 1206 [3216 Metric], Thick Film, General Purpose | https://be.farnell.com/multicomp/mcwr12x1004ftl/res-1m-1-0-25w-thick-film/dp/2447478?st=1m%20%201206 |

| farnell | 2849874 | U | 1 | SOIC | STMICROELECTRONICS | TL071CDT | Operational Amplifier, 1 Amplifier, 4 MHz, 16 V/µs, 6V to 36V, SOIC, 8 Pins | https://be.farnell.com/stmicroelectronics/tl071cdt/so-08-15-jede-single-j-fet-op/dp/2849874?st=tl071 |

The built-up circuit:

Measurements and Use with a DAQ

Here's a scope capture when performing the same torture on the disk as in the first section: ticking it with a plastic pen:

This is good behaviour. The signal stays within the voltage rails. For my DAQ this is fine, because it has a 5VPP ac range. If you use a Pi, you'll have to add a little circuit to transform this into the 0 - 3.3VPP range.

This is the device in action:

I then also mounted the industrial piezo accelerometer, and compared the signals in a LabVIEW flow I had made for the original DAQ road test:

Here are the results, showing that the piezo disk is capable of sensing vibrations. And that Michael's circuit delivers a useable output:

Channel 0 is the industrial accelerator, with its signal 3x attenuated compared to Channel 1, the piezo disk. I've also tried if the signal is good enough to detect acceleration and resonance frequency: yes

The frequency, in the FFT bottom of screen, is spot on. The acceleration works too, but note that this is not an accurate value, because I did not specify this device's voltage per gram.

I can specify it, using the industrial accelerometer as data point. That accelerator has this attribute documented (100 mV/g or 10.2 mV/s2).

LTSpice model: kellettdesign.zip

KiCAD project: piezo_charge_circuit_20220821.zip

Thank you for reading.

Top Comments