I’ve been really stuck for hot air tools for ages, every few months checking out the prices, and always giving up!

I decided to bite the bullet and purchase one. I wanted one with a spinning blower (i.e. not a noisy vibrating air pump), and with the blower in the main body of the unit, not integrated in the handle.

I considered these options:

(1) E-bay used JBC JT 6040 tool that looked like it was manufactured in the last century, for £250 (minimum bid, it could have gone higher), with a description that stated “..currently just gauging interest” (Edit: someone purchased that for £260 in the end)

(2) E-bay Weller tool WTHA 1 apparently "new without box", for £500 starting bid, at which it didn’t sell, but it’s now re-listed at a more sensible starting price (Edit: someone purchased that for £610 in the end)

(3) Quick 861DW, new, for £260 including delivery

(4) Atten ST-862D, new, for £190 including delivery

(5) Multicomp MP740784 , new, for £174 including delivery

(6) Quick TR1300A, new, for £320 including delivery

I was really close to choosing option (2), because it is a current model, and I would be able to buy accessories for it. However, £500 is just a bit too high at Xmas time (EDIT: it sold for £610 including delivery at the final bid by someone, so I'm glad I didn't wait the week bidding for it) especially since I would only use it intermittently because I can always fallback to doing some surface-mount work with a normal soldering iron, I prefer the soldering iron for the simpler components such as SOIC, TSSOP, etc. I wanted the hot air tool for the more complicated packaged components.

I ruled (1) out almost immediately, since perhaps the seller isn’t even sure what price to sell it at, and it all looked pretty ugly. Blowers and other parts can wear out, and it could be a nightmare to fix if/when it goes wrong.

I considered (4) and (5) to be near-similar options, and with hindsight, I should have chosen one of those. I didn’t at the time, because option (4) used a courier service that I wasn’t happy with, and option (5) was currently out of stock.

That left options (3) and (6). Since the price difference was not much between the two, I went with the newer model, i.e. option (6).

It’s a beast, absolutely huge. That’s a negative since it means I won’t keep it on the bench all the time. I’ve placed it on a mini-shelf because I just cannot see myself leaving it on the main desk surface with the fat hose covering a huge portion of the desk too. Now I can see why people would prefer an integrated soldering station and hot air station. Otherwise, it's just too much equipment footprint.

I used a laptop stand for the photo above, but I will replace that with a better stand when I use it, I've seen a little desktop speaker stand that will be ideal. I will probably put the Quick device away to keep the desk clear when I don’t need it.

I’ve not used it yet, I only powered it up and checked that the air and heat work. The display is great. The entire unit looks well built. The handle sometimes tends to stick in the stand, it doesn’t always easily lift out with one hand. That’s slightly annoying.

The nozzles are really nice, they click on and off nicely without a lot of effort, and I think they are identical to the Quick 861DW nozzles. The unit came with three straight nozzles, and I purchased a couple of angled ones from the same seller, they were very low-cost.

Just as a size comparison, the photo below shows the tiny Metcal HCT2-120 alongside the Quick unit. They are not really comparable in heating performance. The Metcal unit is used frequently, since it’s excellent for connectors/wires, for heat-shrink purposes. It’s like a super-accurate heat gun. There is a newer HCT2-200 model which would be a better choice than the HCT2-120 nowadays.

For the Quick unit, I will use it with a pre-heater – I have a very basic one called TMT-PH200. It uses quartz infra-red heating tubes, which tend to cook the face if you get too close to the board! I don't think I can recommend it. It's OK-ish for the price but that's it.

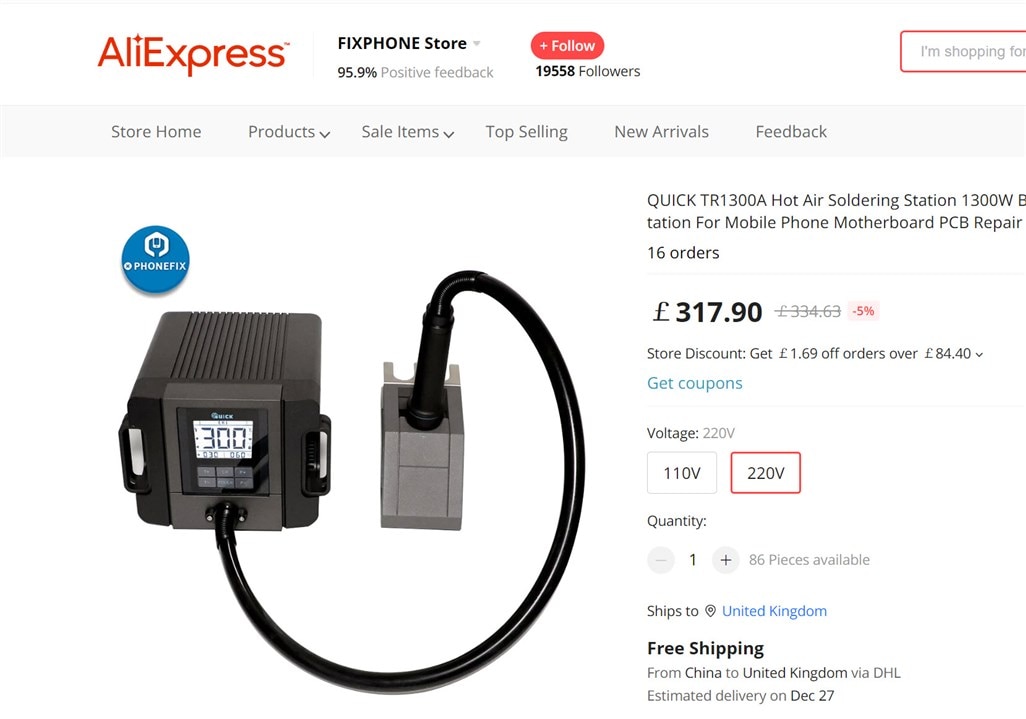

If anyone needs the info, I got the Quick TR1300A from the seller in the screenshot below:

But, if one really doesn't have the desk space and needs a hot air tool, then I believe the Atten or Multicomp products would be a far better option, (for occasional work, otherwise something like Weller/Metcal/JBC would be preferred!), since the ST-862D has excellent reviews. If you have other suggestions, it would be great to hear them, since everyone needs to find ways of working with surface-mount parts at some stage.

Thanks for reading!