Intro

This episode describe the circuit in my SuperCap Magic Meter. The meter circuitry is designed into an Arduino shield which will plug onto an Arduino Uno R4 Minima. This MCU has a 14 bit A/D and a 12 bit DAC that will be used with the shield, allowing the voltages and currents to the supercapacitor under test to be measured and controlled. There is a 6 position rotary switch that selects which mode the meter will operate in. The charging circuit will charge at a constant 100 mA and the discharging circuit will discharge at a programmable rate set by the DAC. The reason for doing the schematic now is that I need to get the PCB on order to stay on schedule.

The SuperCap Meter Circuit

Here is a description of the circuit and how it works:

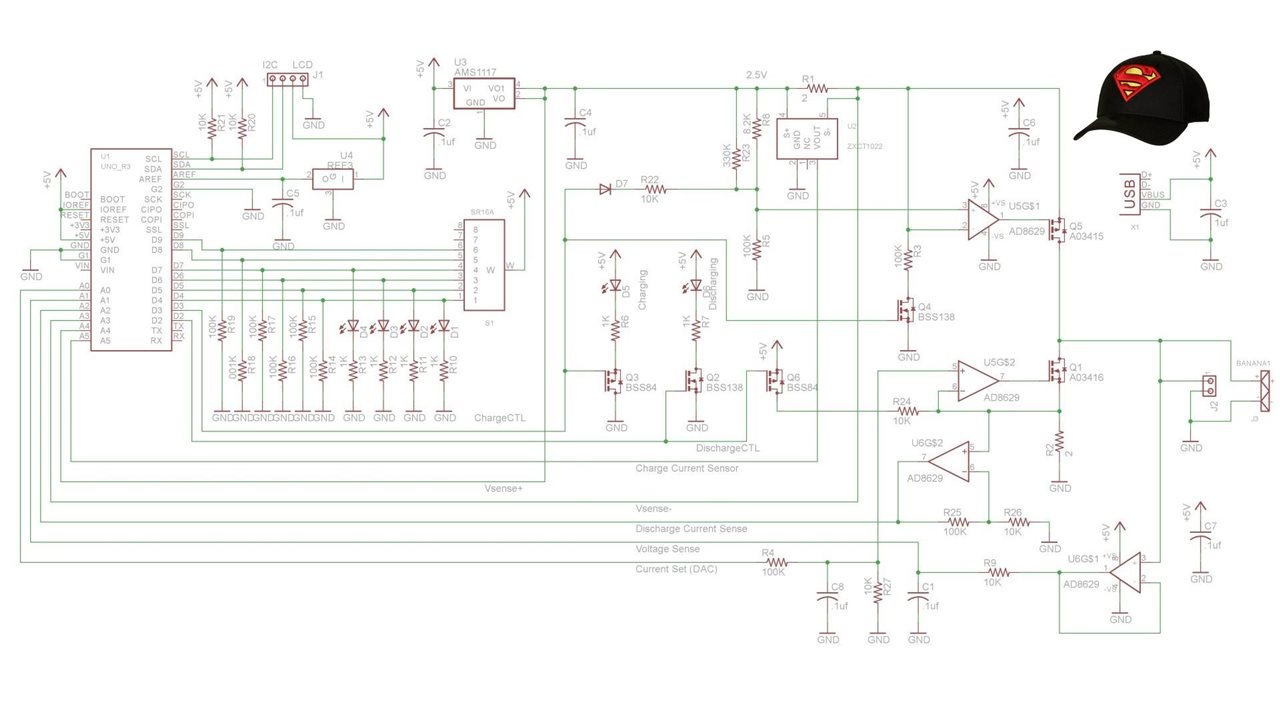

Here is the schematic of the supercapacitor meter shield:

Basically the circuit includes a constant current source fixed at around 100 mA and a separate variable current sink, both can be turned on and off by the UNO R4, which also can monitor voltages across both current shunts and across the supercapacitor under test. It also controls measurement cycles and the precise timing involved. Those cycles will be described in the software blog when the software has been tested. However you can deduce that for a constant current, capacitance can be calculated from the time taken to charge the capacitor. (C=i*dt/dv).

Since this is a one-off build, all voltages and currents can be calibrated by measurement with bench instrumentation. The discharge current is controlled by a DAC on the MCU. This is needed since the recommended measurement method suggests the discharge current should be 1 mA/F. All opamps are chopper-stabilized to minimize errors due to offset voltages and offset drift. The capacitor voltage measurement is buffered by a high impedance unity gain amp to minimize stray leakage from the supercapacitor under test. There are a couple of extra control FETs to ensure the current shuts off completely when the MCU wants it off.

There is an redundant current sense chip which will not be populated because it doesn't improve current measurement accuracy.

There are still a couple of tweaks in the works, such as adding more test points, but the PCB will be complete in a day or so..

Discussion

The PCB is being designed early to allow time for it to be fabricated. This is before the software can be worked on so it needs to have enough flexibility to accommodate software revisions. I did think about how the firmware might help improve performance and accuracy, but that is a lot different than writing code. The Uno R4 has a USB port that allows interfacing to a host computer if the instrument needs to eventually talk to other instruments and computers, however that is not in the plan for this project. Some of the design choices for the system were dictated by what I had on hand, but there is also a significant amount of ordering to procure everything needed. At this time there is so much planning and design work going on, it is tough to put blogs together.

This circuit took longer than expected to design and has morphed quite a bit as I learned more about how supercapacitors work and what needs to be done to measure their parameters.

Next I need to spend time on the other 5 systems to get their PCBs designed and make sure all needed parts are at least on order. I have already ordered a bunch of stuff, but until the detailed design is done, I won't be sure I have everything on order.

Links:

The SuperCap Magic Meter Shield

SuperCap Meter Shield Functional Test

SuperCap Magic Meter - Operational

SuperCap Magic Meter - Experimenting with Supercapacitors

Experimenting with Supercapacitors Design Challenge

Cornell Dubilier Supercapacitor Technical Guide