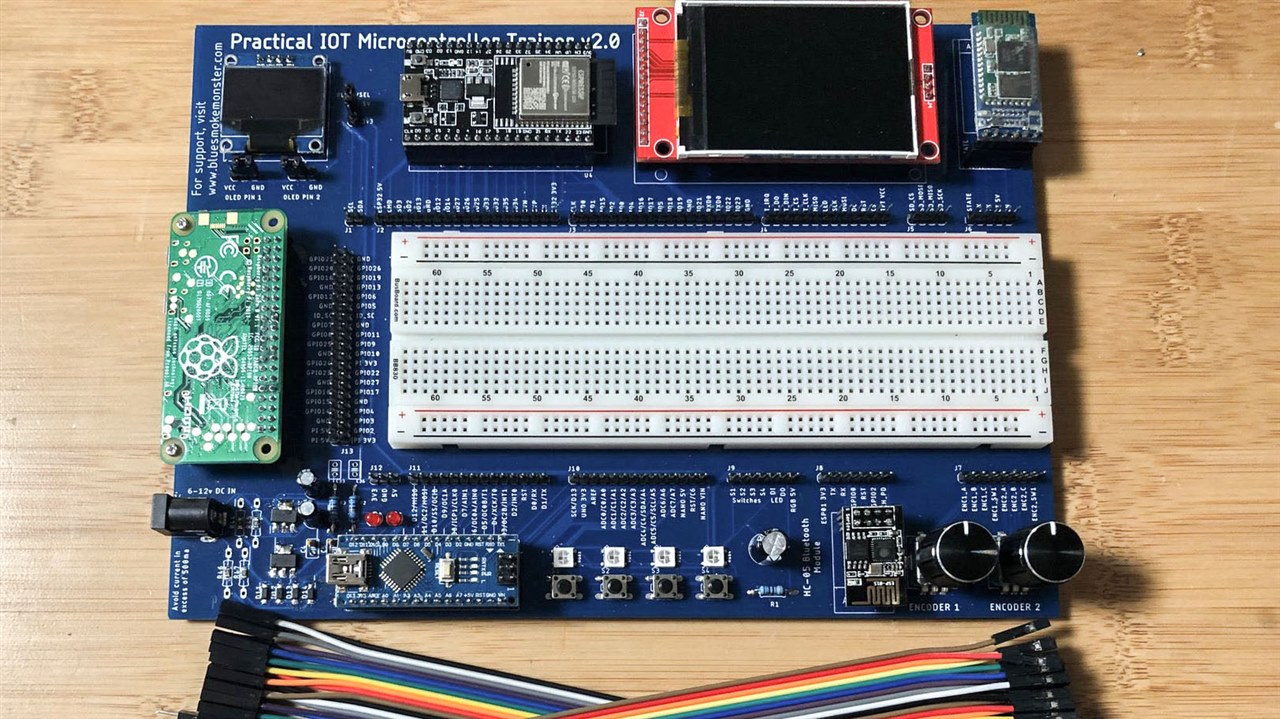

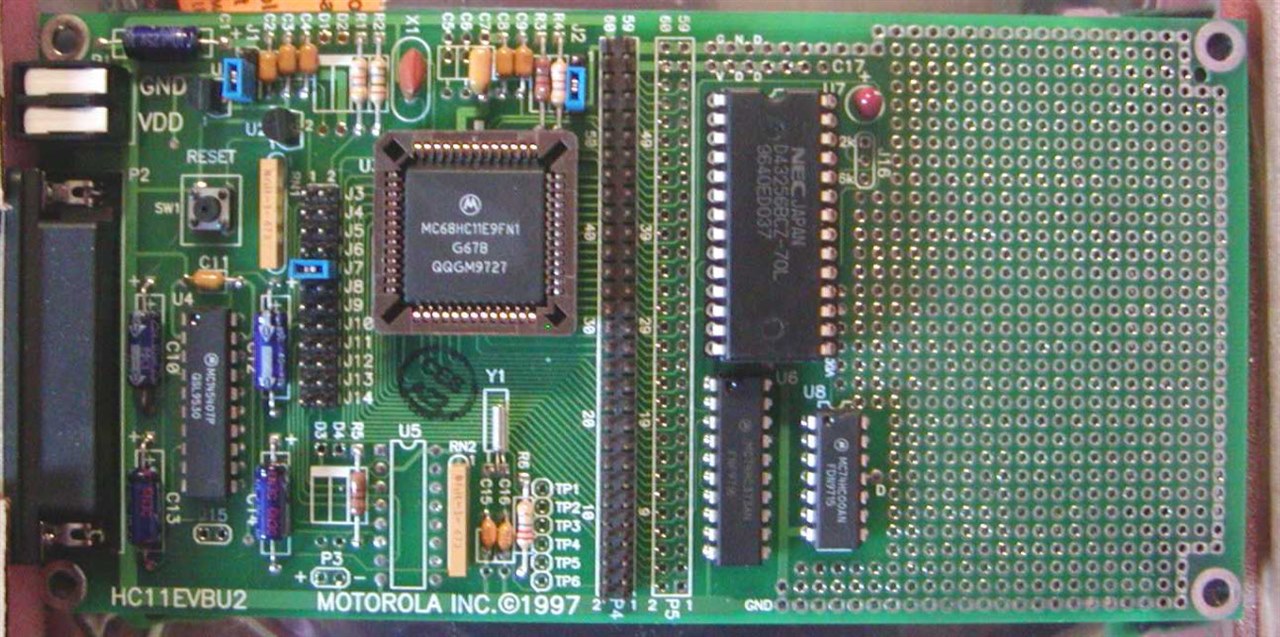

A couple of weeks ago, I bribed shabaz (with coffee) to send me one of his Pi PIco Eurocards. As the name implies, these are a development board for the Pi Pico / RP2040. In the past, another friend sent me one of his all-in-one microcontroller development boards (pictured above). And I have designed a few boards that had development features on them. Besides those, boards like Adafruit's Feathers or even the iconic Arduino Uno could be considered dev boards. Last, historically, microcontroller manufacturers had elaborate evaluation platforms for their chips.

All of these points made me wonder: what are the features YOU want to see in a microcontroller development board?

If we use shabaz's Eurocard, some notable features are:

- Headers for changing power source (external / Pi Pico / Programmer)

- Integrated programmer/debugger (RP2040-based Xiao, in this case)

- Prototype areas for through-hole and surface mount parts

- SD Card

- Button

- LED

- (and many more)

In addition to features, what tricks or tips have people learned when making a board like this one?

(Image source: Google Images)

(Image source: Google Images)